Your Donation Will Be Matched 1-to-1! Can You Chip In?

Dear Patron: Please don’t scroll past this. The Internet Archive is a nonprofit fighting for universal access to quality information. We build and maintain all our own systems, but we don’t charge for access, sell user information, or run ads. Instead, we’re powered by online donations averaging about $14. We’d be deeply grateful if you’d join the one in a thousand users that support us financially.

Right now, we have a matching gift campaign that will double the impact of every donation. We understand that not everyone can donate right now, but if you can afford to contribute this Wednesday, we promise it will be put to good use. Our resources are crucial for knowledge lovers everywhere—so if you find all these bits and bytes useful, please pitch in.

Your Donation Will Be Matched! Can You Chip In?

Dear Patron: Please don’t scroll past this. Right now we have a matching gift campaign that will double the impact of every donation. We understand that not everyone can give right now, but if you can afford to contribute this Wednesday, we promise it will be put to good use. If you find all these bits and bytes useful, please pitch in.

|

MILKSHAKE AND SOFT-SERVE MACHINES |

SS 3 |

Taylor Company

Milkshake and Soft-serve Machine

Model C602

Daily maintenance tasks

|

SS 3 D1 |

Opening |

|

procedures |

|

|

SS 3 D2 |

Closing procedures |

Weekly maintenance tasks

SS 3 W1 Clean and sanitize syrup lines with duckbill valves

SS 3 W2 Clean hot sundae topping water baths

SS 3 W3 Clean and sanitize hot sundae topping pumps

Bi-weekly maintenance tasks

SS 3 B1 14 day brush cleaning

Monthly maintenance tasks

|

SS 3 M1 |

Calibrate hopper |

|

|

temperatures |

||

|

SS 3 M2 |

Calibrate draw |

|

|

temperatures |

||

|

SS 3 |

M3 |

Calibrate hot |

|

sundae topping |

||

|

temperatures and |

||

|

volumes |

||

|

Quarterly maintenance tasks |

||

|

SS 3 |

Q1 |

Replace soft-serve |

|

mix scraper blades |

||

|

SS 3 |

Q2 |

Clean non- |

|

aluminum air filter |

||

|

SS 3 |

Q3 |

Replace machine |

|

components |

Semi-annual maintenance tasks

SS 3 S1 Replace milkshake mix scraper blades

Annual maintenance tasks

|

SS 3 A1 |

Replace syrup |

|

pump tubes |

|

|

SS 3 A2 |

Replace non- |

|

aluminum air filter |

Model C602

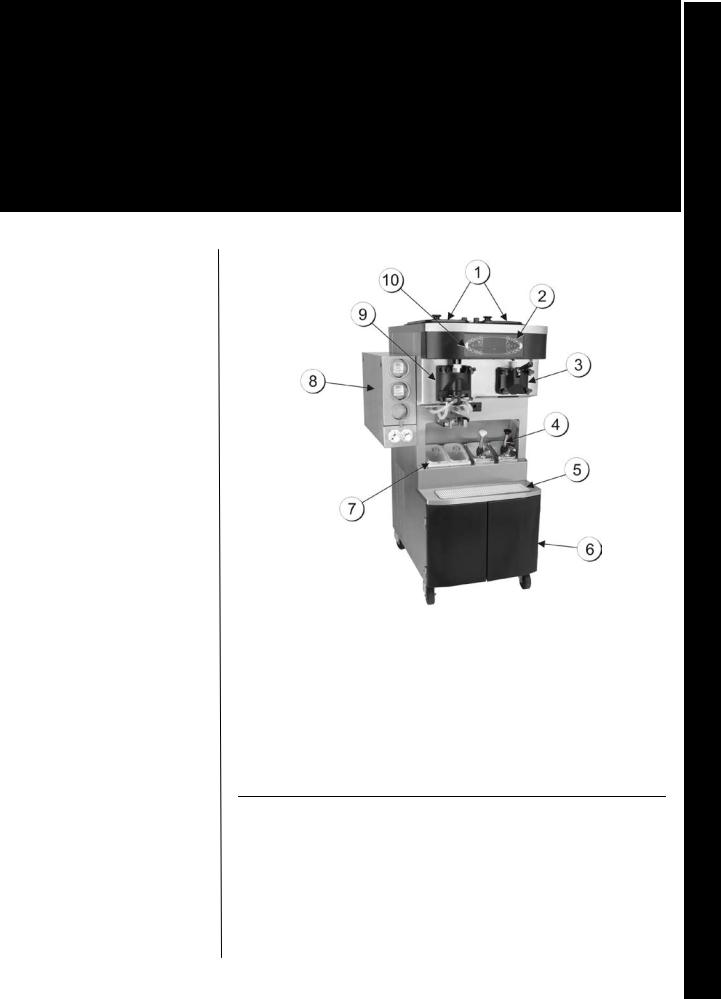

|

1. |

Hopper Covers |

6. |

Cabinet Doors |

|

2. |

Keypad-Soft Serve |

7. |

Cold Topping Containers |

|

3. |

Soft Serve Door Assembly |

8. |

Cup & Cone Dispenser |

|

4. |

Topping Pump |

9. |

Shake Door Assembly |

|

5. |

Drip Tray/Splash Shield |

10. |

Keypad-Shake |

These icons alert you to a possible risk of personal injury.

Look for this icon to find information about how to avoid damaging the equipment while doing a procedure.

Look for this icon to find helpful tips about how to do a procedure.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021

<![if ! IE]>

<![endif]>C602 model machine serve-soft and milkshake Company Taylor

<![if ! IE]>

<![endif]>3 SS

|

Opening Procedures |

Daily |

SS 3 D1 |

|||||||||

|

Why |

Prepare Milkshake/Soft-Serve machine for serving |

||||||||||

|

Time required |

product after the heat treatment cycle is completed |

||||||||||

|

5 minutes to prepare |

30 minutes to complete |

||||||||||

|

Time of day |

When store opens in the morning |

24-hour restaurants: during low-volume periods |

|||||||||

|

Hazard icons |

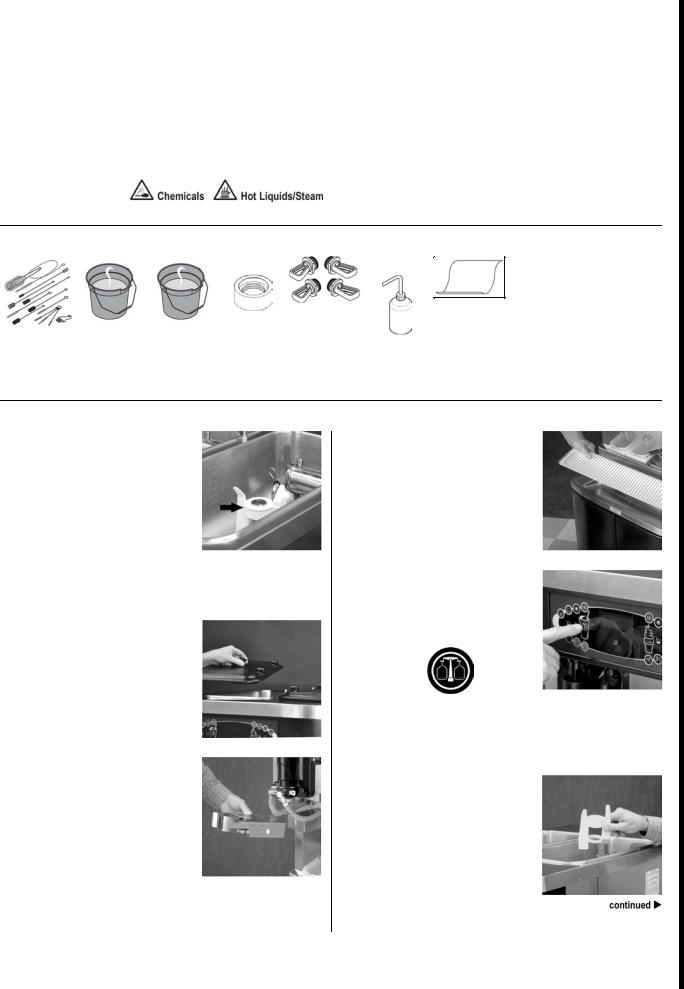

Tools and supplies

|

Brushes |

Bucket with Kay 5 |

Kay 5 |

Taylor Seal |

Taylor Lube HP |

Clean Sanitized |

|

Sanitizing Solution |

Sanitizing |

Install / |

Towels |

||

|

Solution |

Removal Tool |

Procedure – Set Up

1Fill heated topping wells with clean water.

Remove the topping containers. Fill the heated wells with clean water, up to the fill line located on the bottom of the well.

2Place topping heaters in ON position.

Place the topping heaters in the ON position by touching the topping heater symbols.

Note: Clean and sanitize topping containers, topping pumps, and heated wells weekly. (See PM cards SS01 W2 & W3.)

3Fill topping containers.

Fill the topping containers. Place the caramel and fudge topping containers in the heated wells and the remaining two containers in the unheated wells. Cover the containers.

4Sanitize topping ladles.

Sanitize the topping ladles and place them in the cold topping containers.

5Fill cup dispensers, cup lid holder and cone dispenser.

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 1 of 4 |

<![if ! IE]>

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]>

<![endif]>3 SS Daily

<![if ! IE]>

<![endif]>D1

Opening Procedures (continued)

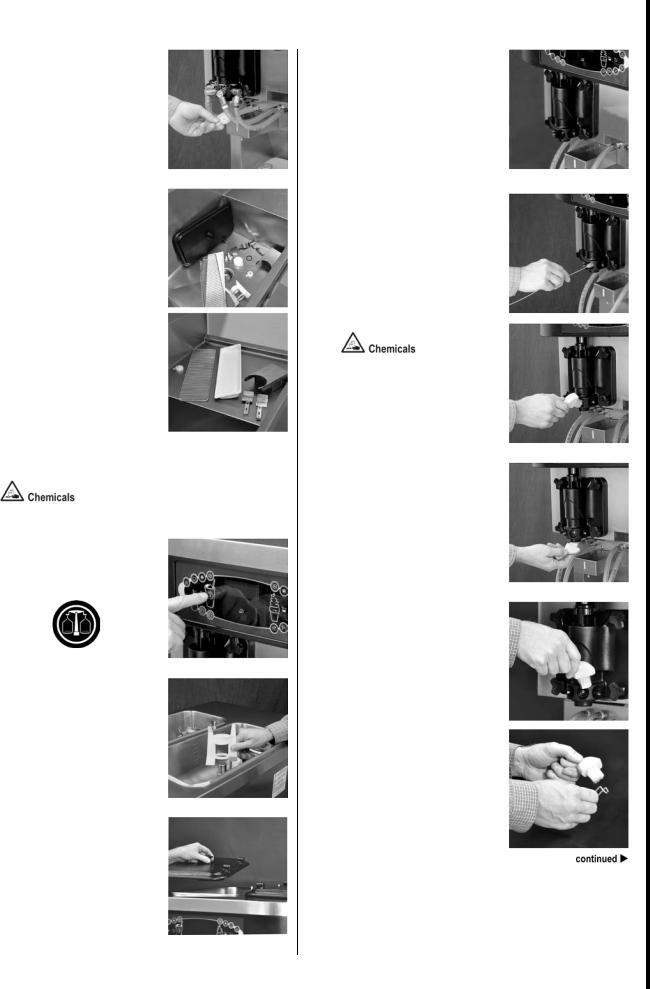

Procedure – Shake Side

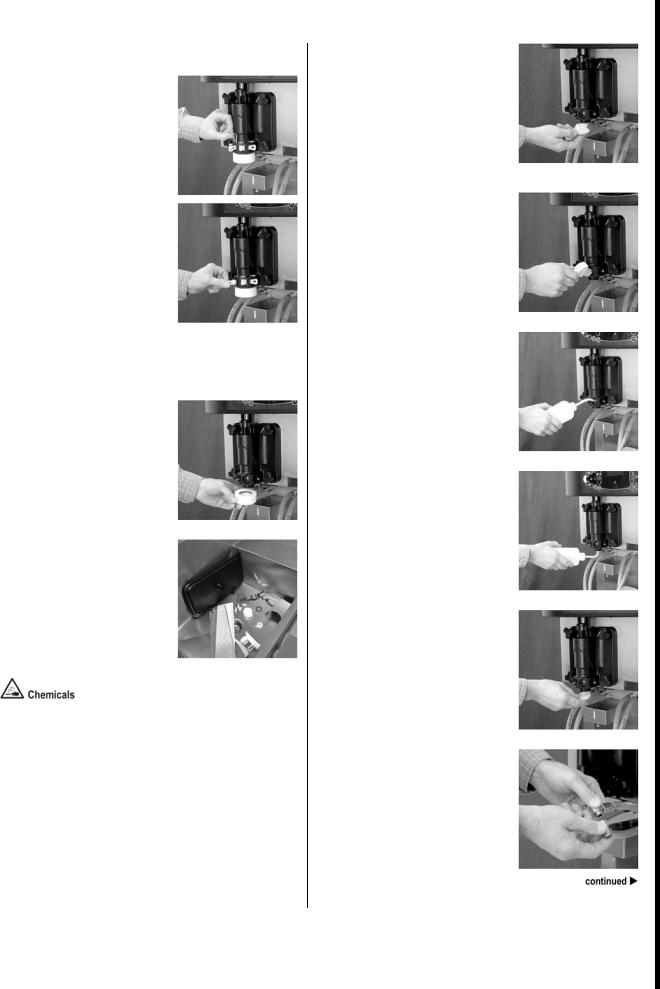

1Remove syrup valve retainers and syrup hole plugs.

Remove the syrup valve retainers and the syrup hole plugs.

Remove the o-rings from the syrup hole plugs.

2Remove draw valve cap.

Remove the draw valve cap and remove the o-ring.

3Sanitize parts.

Prepare a small amount of KAY-5 Sanitizer solution. Sanitize the o-rings, restrictor cap, syrup hole plugs, syrup valve retainers, draw valve cap, shake cup holder, front drip tray, and splash shield in this solution.

Sanitizer Solution

4Sanitize door spout, driven spinner, spinner blade, and syrup line fittings.

Brush clean each item for a total of 60 seconds, repeatedly dipping the brush in sanitizing solution.

5Sanitize syrup port holes.

Place a pail below the door spout.

Brush each syrup port hole 10 to 15 times. Dip the brush in sanitizing solution before brushing each port.

6Flush syrup port holes with sanitizing solution.

Insert tube end of squeeze bottle into each syrup port and squeeze the bottle firmly. Flush each port for 10 seconds.

7Flush door spout with sanitizing solution.

Flush the bottom of the door spout door with sanitizing solution.

8Install syrup valve retainers and restrictor cap on door spout.

9Remove syrup nose fittings.

Remove the syrup nose fitting from each syrup line by turning the syrup nose fitting counter-clockwise.

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 2 of 4 |

<![if ! IE]>

<![endif]>m rvesC l mod-softchineand milkshake Company Taylor

<![if ! IE]>

<![endif]>602

<![if ! IE]>

<![endif]>Daily

<![if ! IE]>

<![endif]>D1 3 SS

Opening Procedures (continued)

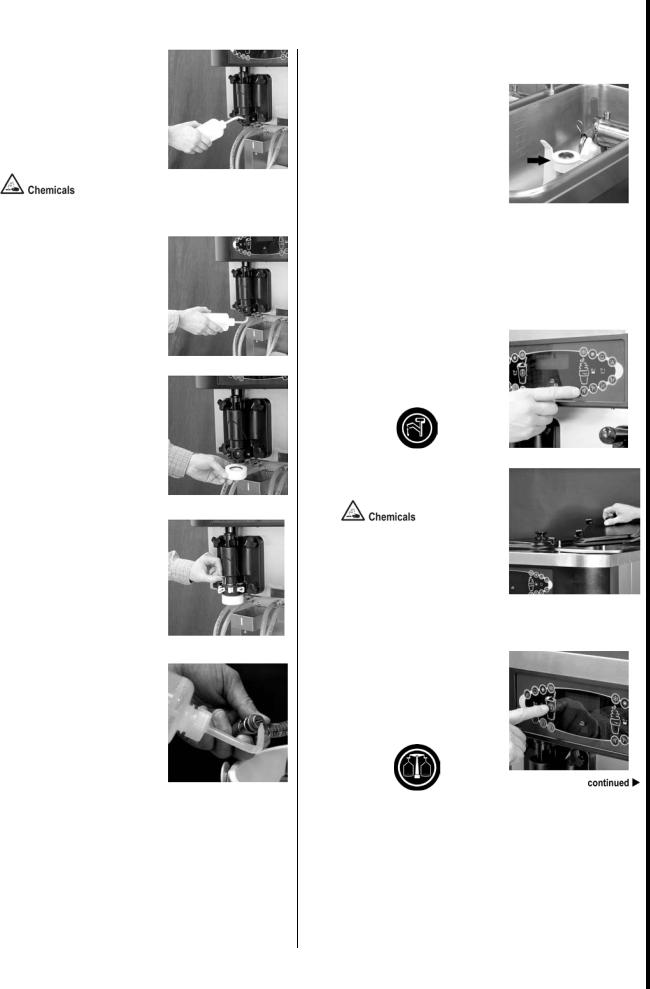

10Remove duckbill valve.

Remove the duckbill valve and the o-ring from each syrup nose fitting, by using the seal removal tool.

11Clean syrup nose fitting.

Using a brush and the sanitizing solution, brush clean the inside of each syrup nose fitting until there is no remaining syrup or mix inside the fitting.

12Sanitize syrup nose fittings and duckbill valve.

Using a clean, sanitized towel, gently wipe any syrup and mix from each duckbill valve.

Use a milkshake cup filled with sanitizing solution to thoroughly rinse the nose fittings and duckbill valve.

13Install duckbill valve into syrup nose fitting and install syrup nose fitting onto syrup line fitting.

Install the duckbill valve into the syrup nose fitting with the flat end aligned with the open slot in the fitting.

Install the syrup nose fitting onto the syrup line fitting. Tighten by hand (clockwise) until snug.

Install and lubricate the o-ring on the syrup nose fitting.

14Install syrup valves.

Raise the syrup valve retainer and install the syrup valve. Push the retainer down to hold the valve in place. Repeat for each syrup valve.

15Check syrup lines for air pockets in the line.

If air pockets are present, prime the syrup lines. (See Operator Manual for priming syrup lines.)

16Install syrup plugs for unused syrup lines.

Install a syrup hole plug into the syrup port in the door whenever a syrup line is not in use. (Example: When the optional flavor shake is not being served.)

Do not install an empty syrup line into the syrup port of an unused syrup line.

Note: The syrup system must be flushed and sanitized weekly.

(See PM card SS01 W1)

17Wipe exterior of machine.

Using a clean, sanitized towel, wipe down the freezer door, front panel, and other areas that have a build up of moisture or food substance.

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 3 of 4 |

<![if ! IE]>

<![endif]>m rvesC l mod-softchineand milkshake Company Taylor

<![if ! IE]>

<![endif]>602

<![if ! IE]>

<![endif]>Daily

<![if ! IE]>

<![endif]>D1 3 SS

Opening Procedures (continued)

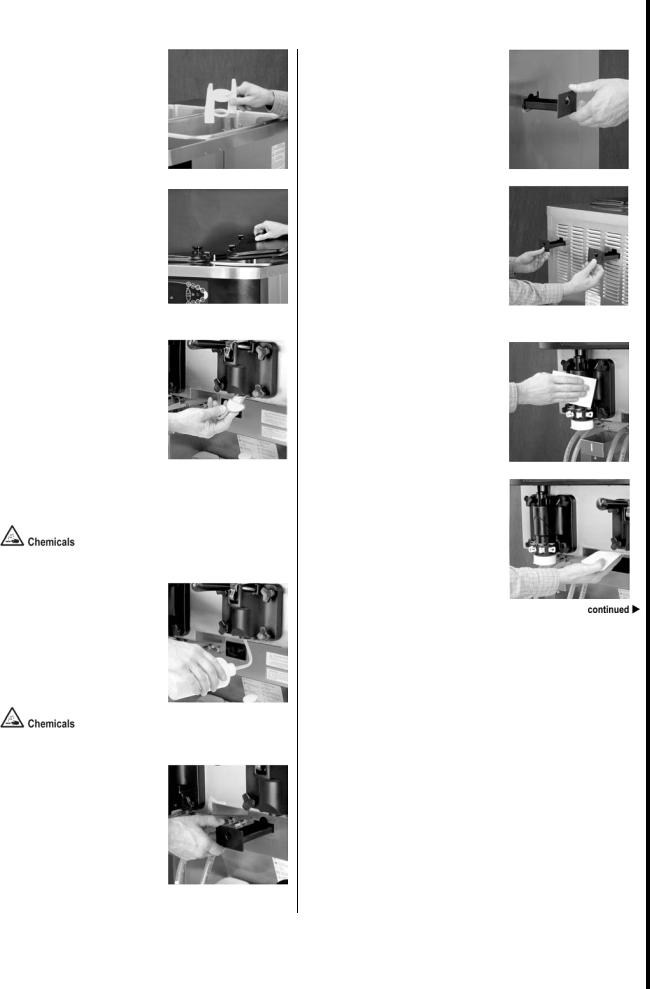

18Install shake cup holder, front drip tray and splash shield.

19Select the AUTO symbol.

When ready to resume normal operation, touch the AUTO symbol. The frozen product should be ready to serve in approximately 10 minutes.

Note: This step should be performed approximately 15 minutes prior to serving product.

Procedure – Soft Serve Side

1Sanitize door spout and bottom of draw valve.

With a pail placed beneath the soft serve door, dip the door spout brush in sanitizing solution. Brush clean the door spout and bottom of the draw valve. Repeatedly dip the brush in sanitizing solution and brush clean each item for 60 seconds.

2Flush door spout and bottom of draw valve with sanitizing solution.

Use the squeeze bottle filled with sanitizing solution to flush the door spout and bottom of the draw valve.

3Wipe exterior of machine.

Using a clean, sanitized towel, wipe down the freezer door, front panel, and other areas that have a build up of moisture or food substance.

4Select the AUTO symbol.

When ready to resume normal operation, touch the AUTO symbol. The frozen product should be ready to serve in approximately 10 minutes.

Note: This step should be performed approximately 15 minutes prior to serving product.

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 4 of 4 |

<![if ! IE]>

<![endif]>m rvesC l mod-softchineand milkshake Company Taylor

<![if ! IE]>

<![endif]>602

<![if ! IE]>

<![endif]>Daily

<![if ! IE]>

<![endif]>D1 3 SS

|

Closing Procedures |

Daily |

SS 3 D2 |

|||||||||

|

Why |

Prepare Milkshake/Soft-Serve machine for the heat treatment cycle |

||||||||||

|

Time required |

30 minutes |

||||||||||

|

Time of day |

At closing |

24-hour restaurants: one hour before heat treatment cycle |

begins

Hazard icons

Tools and supplies

|

Brushes |

SolidSense All |

Kay 5 Sanitizing |

Valve Cap |

Syrup Hole Plugs |

Kay 5 Sanitizing |

Clean Sanitized |

|

Purpose Super |

Solution |

Solution |

Towels |

|||

|

Concentrate (APSC) |

||||||

|

Solution |

Procedure – Shake Side

1Fill mix hopper.

Fill the hopper with fresh mix, up to the line on the agitator paddle. Do not fill above the agitator paddle.

Important: The level of mix in the hopper must be at the line on the agitator paddle. The mix low light must not be on.

2Remove hopper cover.

3Remove milkshake cup holder.

4Remove drip tray and splash shield.

5Remove agitator paddle.

Select the calibrate symbol to momentarily stop the agitator paddle from turning.

Important: Make sure your hands are clean and sanitized before performing the next steps.

With sanitized hands, remove the agitator paddle from the hopper.

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 1 of 5 |

<![if ! IE]>

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]>

<![endif]>Daily

<![if ! IE]>

<![endif]>3 SS

<![if ! IE]>

<![endif]>D2

Closing Procedures (continued)

6Remove restrictor cap.

Remove the restrictor cap from the door spout.

7Clean and sanitize parts.

At the sink, brush clean and sanitize:

Agitator paddle

Hopper cover

Milkshake cup holder

Milkshake restrictor cap

Drip tray

Splash shield

Syrup hole plugs

Spout cap

Spout cap o-ring

Place the restrictor cap, splash shield, drip tray, and milkshake cup holder on a clean, dry surface to air dry overnight or until the heat treatment cycle is complete.

APSC & Sanitizer solution

8Install agitator paddle.

Select the calibrate symbol to momentarily stop the agitator drive motor.

Using sanitized hands, reinstall the agitator paddle on the drive post in the hopper.

9Install hopper cover.

10Remove syrup lines.

Raise the retaining pins and remove the syrup valves.

11Clean syrup port holes.

Place a bucket beneath the door. Brush clean each syrup port hole 10 to 15 times. Dip the brush in cleaning solution before brushing each port.

Brush each item for a total of 60 seconds.

APSC solution

12Clean door spout, bottom of driven spinner, spinner blade and syrup line fittings.

Brush clean each item for a total of 60 seconds, repeatedly dipping the brush in cleaning solution.

13Clean syrup valve retainers and holes.

With sanitized hands, remove the syrup valve retainers. Dip the brush in cleaning solution and brush clean the retainers and the retainer holes. Reinstall the syrup valve retainers.

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 2 of 5 |

<![if ! IE]>

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]>

<![endif]>3 SS Daily

<![if ! IE]>

<![endif]>D2

Closing Procedures (continued)

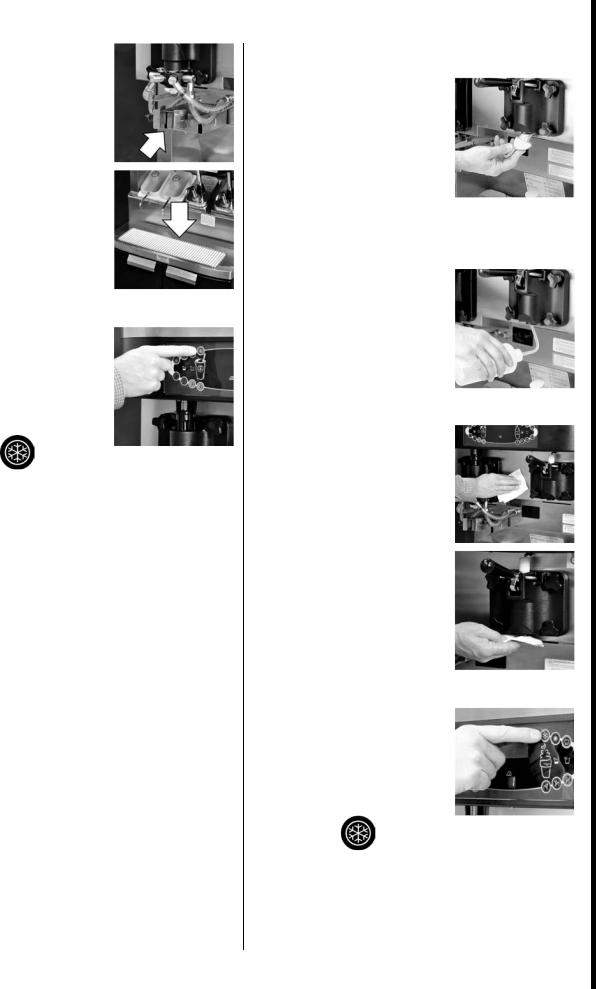

14Flush syrup port holes with sanitizing solution.

Insert the tube end of the squeeze bottle filled with sanitizing solution into each syrup port. Squeeze the bottle firmly. Flush each port for 10 seconds.

APSC solution

15Flush door spout with sanitizing solution.

Flush the bottom of the door spout door with sanitizing solution.

16Fill valve cap with sanitizing solution and install.

Fill the insulated valve cap with sanitizing solution and install the cap onto the milkshake door spout.

17Install syrup hole plugs.

Raise the retainer pins. Install a syrup hole plug into each syrup port. Lower the retainer pins to secure the syrup hole plugs.

18Sanitize syrup nose fittings.

Hold the squeeze bottle over a bucket. Squeeze the bottle and thoroughly rinse the slot of each syrup nose fitting.

Wipe the outside of the syrup nose fittings with a clean, sanitized towel.

Note: The syrup system must be flushed and sanitized weekly.

(See PM card SS01 W1.)

Procedure – Soft Serve Side

1Fill mix hopper.

Fill the hopper with fresh mix, up to the line on the agitator paddle. Do not fill the mix hopper above the agitator paddle.

Important: The level of mix in the hopper must be at the line on the agitator paddle. The mix low light must not be on.

2Place topping heaters in OFF position.

Turn the topping heaters OFF by selecting the topping heater symbols.

3Remove, clean, and sanitize hopper cover.

APSC & Sanitizer solution

4Remove, clean, sanitize, and reinstall agitator paddle.

Select the calibrate symbol to momentarily stop the agitator paddle from turning.

Important: Make sure your hands are clean and sanitized before performing the next steps.

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 3 of 5 |

<![if ! IE]>

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]>

<![endif]>3 SS Daily

<![if ! IE]>

<![endif]>D2

Closing Procedures (continued)

Remove the agitator paddle from the hopper and take it to the sink. Brush clean, sanitize, and reinstall the agitator paddle.

5 Install hopper cover.

6Clean door spout and bottom of draw valve.

Place a bucket beneath the soft-serve door. Dip the door spout brush into cleaning solution and brush clean the door spout and bottom of the draw valve. Repeatedly dip the brush in cleaning solution and brush clean each item for 60 seconds.

APSC solution

7Flush door spout with sanitizing solution.

Use the squeeze bottle filled with sanitizing solution to rinse the bottom of the door spout. Rinse the spout with sanitizing solution for 10 seconds.

Sanitizer solution

8Remove, clean and reinstall drip pans.

Remove the drip pans and take them to the sink. Brush clean, sanitize, and reinstall the drip pans.

Note: Mix in the drip pans indicates there is a leak that needs to be corrected before damage occurs inside the machine.

Examples:

If mix is in the front or side drip pans, inspect/replace the beater drive shaft seals. If mix is in the rear drip pan, inspect/replace the pump drive shaft seals.

9Wipe exterior of machine.

Use a clean, sanitized towel to wipe down the freezer doors, front panels, and any other areas that have a build-up of either moisture or food substance.

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 4 of 5 |

<![if ! IE]>

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]>

<![endif]>3 SS Daily

<![if ! IE]>

<![endif]>D2

Closing Procedures (continued)

10 Make sure unit is in AUTO.

Note: The machine must be in AUTO (or STANDBY) to start the heat treatment cycle at the programmed time.

DO NOT attempt to draw product or disassemble the machine during the HEAT cycle. The product is hot and under extreme pressure.

When the heat cycle is complete, the control panel will change to the STANDBY mode. The STANDBY symbols will be illuminated.

<![if ! IE]>

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]>

<![endif]>3 SS Daily

<![if ! IE]>

<![endif]>D2

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 5 of 5 |

|

Clean and sanitize syrup lines with duckbill |

Weekly |

SS 3 W1 |

|||||||||

|

valves |

|||||||||||

|

Why |

To break the bacteria cycle |

||||||||||

|

Time required |

5 minutes to prepare |

20 minutes to complete |

|||||||||

|

Time of day |

At close |

For 24-hour restaurants: during breakfast menu |

|||||||||

|

Hazard icons |

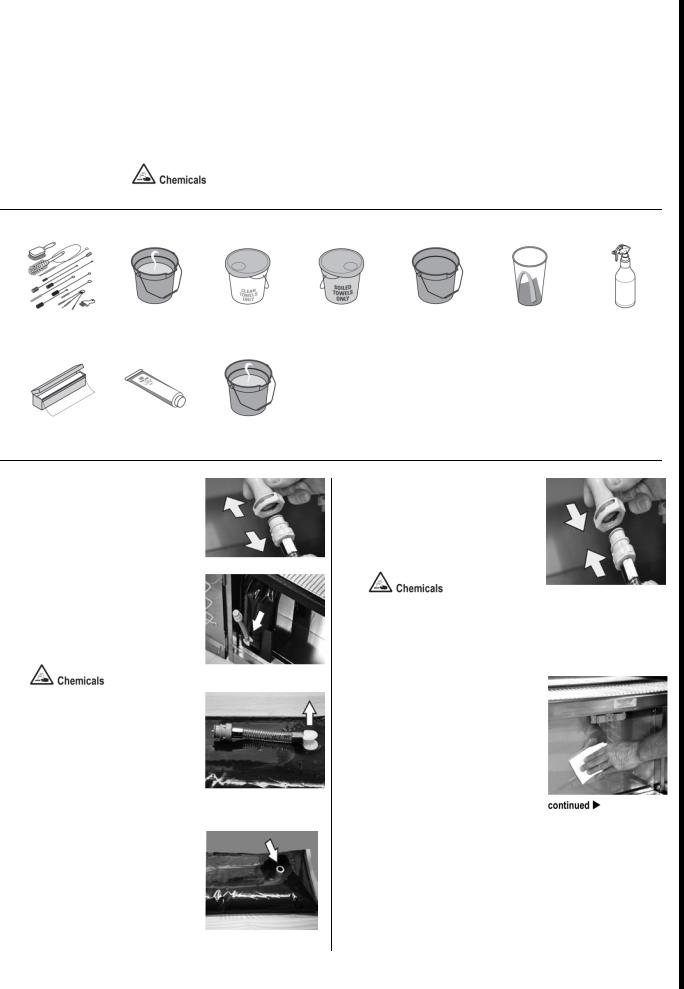

Tools and supplies

|

Brushes |

Bucket, SolidSense |

Bucket, clean and |

Bucket, soiled towels |

Bucket, plastic |

Cold-drink cup |

Kay-5 Sanitizing |

|

All Purpose Super |

sanitizer-soaked |

solution |

||||

|

Concentrate (APSC) |

towels |

|

Plastic wrap |

Taylor Lube HT |

Kay-5 Sanitizing |

|

solution |

Procedure

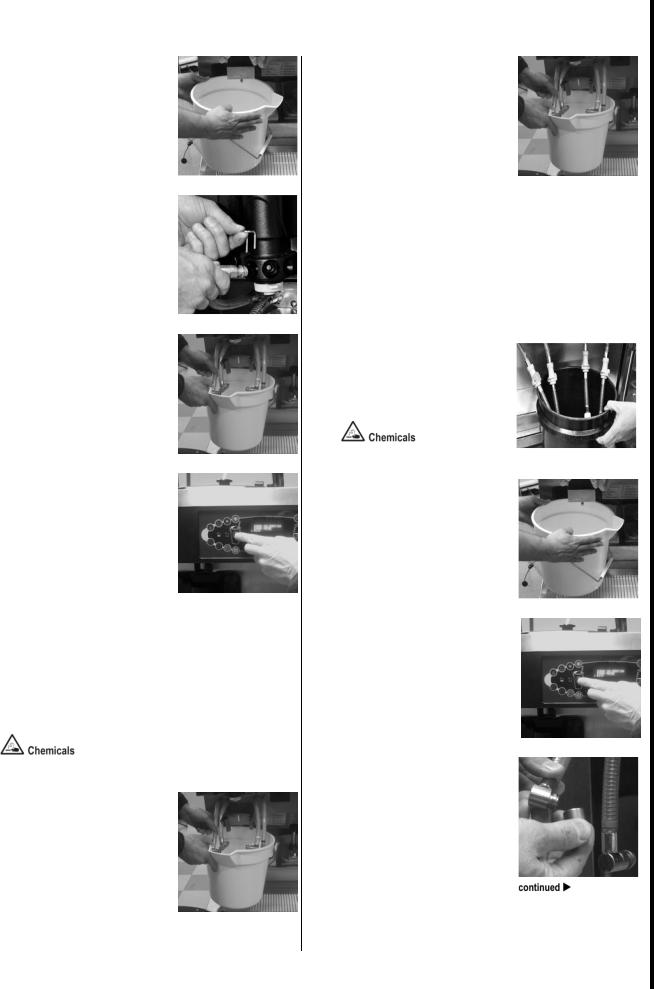

1Disconnect the QD fitting

Disconnect the QD fitting on the syrup bag.

Remove the syrup bags with the line attached from the cabinet.

Wipe the outside of the feed tubes or the hose connector fittings with a clean, sanitizer-soaked towel.

Sanitizer solution

2Place the syrup bag on a level surface. Remove the syrup bag line from the syrup bag.

4Re-connect the QD

Fitting/Hose from the syrup bag

Place the syrup feed hose in a bucket of APSC solution.

APSC Solution

5Clean inside of cabinet.

Wipe down the inside of the syrup cabinet with a clean, sanitizer-soaked towel. Spray resistant areas with additional sanitizer solution.

3Cover the syrup inlet port with plastic wrap.

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 1 of 4 |

<![if ! IE]>

<![endif]>C602 model machine serve-soft and milkshake Company Taylor

<![if ! IE]>

<![endif]>Weekly

<![if ! IE]>

<![endif]>W1 3 SS

Clean and sanitize syrup lines with duckbill valves (continued)

6Place empty bucket under milkshake draw valve.

Place a clean plastic bucket under the milkshake draw valve.

7Remove syrup line from milkshake freezer door.

Disconnect the corresponding syrup line from the milkshake freezer door by raising the syrup valve retainer. Pull the valve straight out.

8Place syrup line and valve in bucket.

Hang the syrup line and valve in the empty bucket.

9Start flow of APSC solution.

Press the Calibration key on the control panel to display the menu options.

Touch the Auto key to move the arrow to “Syrup Prime.”

Touch the Calibration key again to display the syrup prime screen.

Press the Flavor Select key for the correct flavor, to start the flow of APSC through the line.

APSC solution

10Flush syrup line with APSC solution.

Allow the APSC solution to continue to flow into the empty bucket until all the syrup is flushed from the line. When the liquid from the syrup line runs clear, the line is completely flushed.

11Pump all liquid from syrup line.

Remove the syrup feed tube from the bucket of APSC solution and continue to run the pump until APSC solution no longer runs from the syrup line.

Touch the Flavor Select key to stop the flow of APSC solution through the syrup line.

12Rinse with clean, hot water

Repeat steps 7-10 with clean, hot water.

13Place feed tubes in sanitizer solution.

Place the syrup bag connect fittings into a bucket of sanitizer solution.

Sanitizer solution

14Place empty bucket under milkshake draw valve.

Place a clean plastic bucket under the milkshake draw valve.

15Flush syrup line with sanitizer solution.

Repeat steps 7 through 9 using sanitizer solution.

16Remove nose fitting.

Unscrew the nose fitting from the syrup valve in the bucket by turning the cap counterclockwise.

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 2 of 4 |

<![if ! IE]>

<![endif]>C602 model machine serve-soft and milkshake Company Taylor

<![if ! IE]>

<![endif]>Weekly

<![if ! IE]>

<![endif]>W1 3 SS

Clean and sanitize syrup lines with duckbill valves (continued)

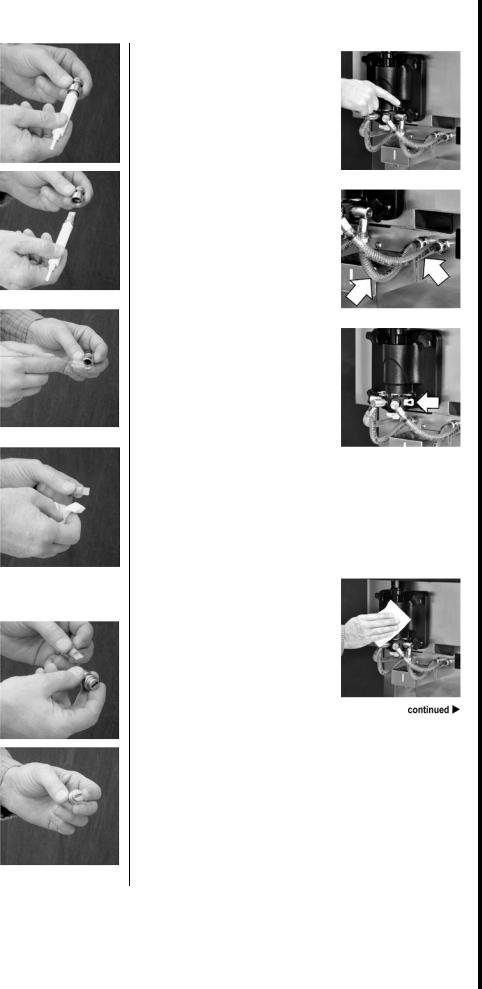

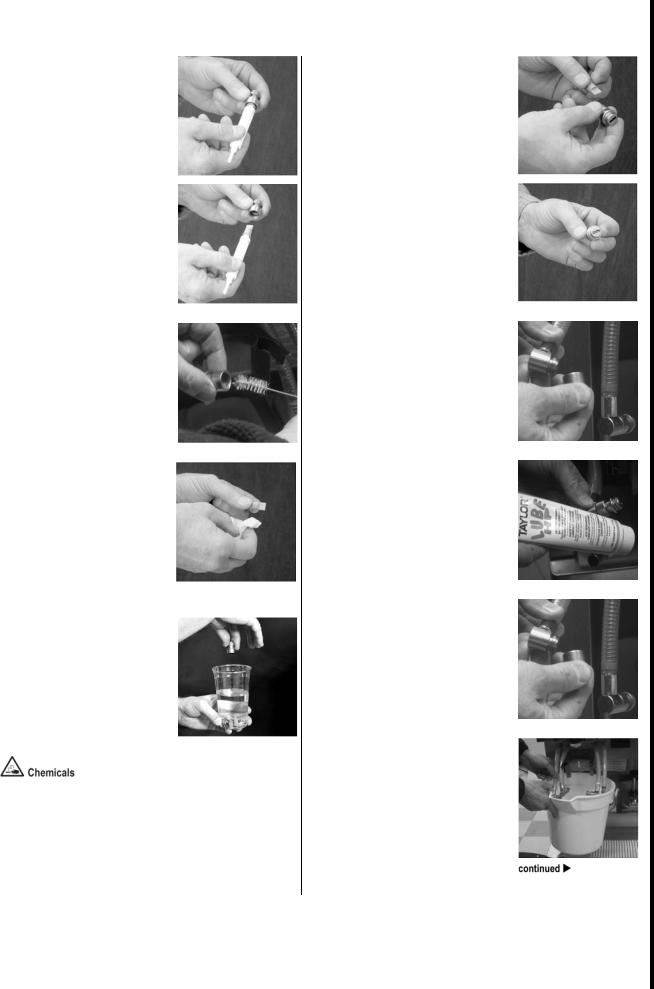

17Remove valve and o-ring.

Remove the duckbill valve and o-ring from each syrup nose fitting, by using the seal removal tool.

18Clean nose and elbow fitting.

Use the white end of the double-ended brush to scrub the inside of the syrup nose fitting and the elbow fitting. Remove any residual particles.

19Clean duckbill valves.

Use a clean, sanitizer-soaked towel to wipe any syrup from the duckbill valves.

20Sanitize syrup valve fittings.

Fill a cup with sanitizer solution. Submerge the syrup valve fittings in the sanitizer solution in the cup. Rotate the cup gently so the fittings are washed thoroughly. Allow to soak for at least one minute.

Sanitizer solution

21Insert duckbill valve.

Install the duckbill valve into one of the nose fittings with the flat end aligned with the open slot in the nose fitting.

Do not lubricate the duckbill valve.

22Connect nose fitting.

Screw the nose fitting onto one of the syrup valve elbows by turning it clockwise. Tighten it by hand until snug.

23Install and lubricate o-ring.

Push one of the o-rings onto the nose fitting and lubricate it with Taylor Lube HP.

24Reassemble remaining valves.

Repeat steps 20 through 22 to reassemble the remaining syrup valves.

25Place clean bucket under milkshake draw valve.

Place a clean plastic bucket under the milkshake draw valve. Position the sanitized valves so they are hanging over the bucket.

|

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 3 of 4 |

<![if ! IE]>

<![endif]>C602 model machine serve-soft and milkshake Company Taylor

<![if ! IE]>

<![endif]>Weekly

<![if ! IE]>

<![endif]>W1 3 SS

-

Page 1

Soft serve/shake combination freezer taylor model c602 place this chapter in the shakes/desserts section of the equipment manual. Manufactured exclusively for mcdonald’s® by taylor® company 750 n. Blackhawk blvd. Rockton, il 61072 phone: (815) 624-8333 toll free number outside illinois: 1 (800) 228-…

-

Page 2

1 introduction the model c602 is a combination shake and soft serve freezer. The soft serve side uses a 3.4 quart (3.2 liter) freezing cylinder with a single spout door. The shake side has a 7 quart (6.6 liter) freezing cylinder with a four flavor dispensing door. The touch panel has four flavor sym…

-

Page 3

2 do not operate the freezer unless all service panels and access doors are restrained with screws. Failure to follow this instruction may result in severe personal injury from hazardous moving parts. Do not attempt to draw product or disassemble the unit during the heat cycle. The product is hot an…

-

Page 4

3 notes :.

-

Page 5

4 parts identification/functions exploded view (see figure 1) item part no. Description qty. Function warr. Class 1 053809-1 cover-hopper*black* 2 protects mix in mix hopper from any debris. Helps keep temperature in mix hopper uniform. 103 2 x44797 agitator assembly 2 stirs product in mix hopper to…

-

Page 6

5 exploded view (continued) item part no. Description qty. Function warr. Class 20 056131 plate-dec. 1 touch sensor display panel on front of machine. 103 21 055957 panel-side left 1 panel which provides access to internal components. 103 22 052779-3 filter-air 18.0 l x 13.5 h x .70 w 2 filters dust…

-

Page 7

6 front view (see figure 2) item part no. Description qty. Function warr. Class 1 x35584ser2 motor a.-spinner 1 turns spinner shaft assembly. 103 2 059462 solenoid -draw valve 1 energized to raise the shake draw valve. 103 3 020108 coupling-flexible w/screws 1 connects spinner motor to coupling asse…

-

Page 8

7 front view (continued) item part no. Description qty. Function warr. Class 15 x53800-brn pump a.-syrup- heated (chocolate) 1 dispenses heated sundae topping. 103 16 x53800-tan pump a.-syrup- heated (caramel) 1 dispenses heated sundae topping. 103 17 056008 holder-cup shake 1 holds cup in place dur…

-

Page 9

8 front view figure 2.

-

Page 10

9 syrup cabinet view (see figure 3) item part no. Description qty. Function warr. Class 1 056016 shelf-syrup 1 provides access to syrup pumps. 103 2 052916 pump-peristaltic 4 pumps syrup to freezer door. 103 3 058725 motor-gear 161 rpm 4 drives peristaltic pump rollers. 103 4 059144 rack-syrup cabin…

-

Page 11

10 mix pump & tubes (see figure 4) item part no. Description qty. Function warr. Class 1 052916 pump-peristaltic 4 contains rollers to propel syrup. 103 2 x54978 kit a.-peristaltic pump tube 4 compressed by pump rollers to propel syrup. 000 3 053036 ferrule-.625 id 2 ea. Clamps syrup hose on fitting…

-

Page 12

11 mix hopper — top view (see figure 5) item part no. Description qty. Function warr. Class 1 x44761 sleeve a.-mix pump 2 hub used to hold the air/mix pump in a locked position. 103 2 x41348 probe a.-mix out 2 electrical device to indicate level of mix in the hopper. Activates the mix out light on f…

-

Page 13

12 x57028-xx pump a. — mix simplified — shake (see figure 6) item part no. Description qty. Function warr. Class 1 — 7 x57028-xx pump a.-mix simplified shake 1 delivers air and mix to the freezing cylinder. 103 1 057944 cylinder-pump- hopper-shake 1 chamber to house the piston. 103 2 x55450 pin a.-r…

-

Page 14

13 x57028-xx pump a. — mix simplified — shake figure 6.

-

Page 15

14 x57029-xx pump a. — mix simplified — soft serve (see figure 7) item part no. Description qty. Function warr. Class 1 — 7 x57029-xx pump a.-mix simplified soft serve 1 delivers air and mix to freezing cylinder. 103 1 057943 cylinder-pump- hopper-soft serve 1 chamber to house the piston. 103 2 x554…

-

Page 16

15 x57029-xx pump a. — mix simplified — soft serve figure 7.

-

Page 17

16 x56652 syrup line assembly — triple thick shake syrup (see figure

item part no. Description qty. Function warr. Class 1 053036 ferrule-.625 id 2 clamps syrup hose on fitting. 000 2 056675 fitting-barb 1 connects syrup lines to front panel. 103 3 500205 o-ring 1 provides seal for quick disconne…

-

Page 18

17 x59304 syrup line assembly — thin viscosity syrup (see figure 9) item part no. Description qty. Function warr. Class 1 029834 ferrule-.650 id 2 clamps syrup hose on fitting. 000 2 056675 fitting-barb 1 connects syrup lines to front panel. 103 3 500205 o-ring 1 provides seal for quick disconnect f…

-

Page 19

18 x58450 syrup line assembly — syrup-in-bag option (see figure 10) item part no. Description qty. Function warr. Class 1 024278 o-ring-1/2 od x .070 1 provides a seal in the pump tube connection. 000 2 054526 fitting-male 1 connects to the pump tube. 103 3 053036 ferrule-.625 id np brass 2 secures …

-

Page 20

19 accessories (see figure 11) item part no. Description qty. Function warr. Class 1 x56121 dispenser a.-cone 1 dispenses shake and soft serve cups and cones. 103 1a 052193 baffle-rubber cone 2 holds and dispenses soft serve cones. 000 2 x58474 kit a.-syrup plug kit 4 seals syrup ports in the shake …

-

Page 21

20 accessories item part no. Description qty. Function warr. Class * x49463-59 kit a.-tune up c602 1 tune up kit containing: 1/x56200-10 pump kit, 1/x56200-12 draw valve kit, 1/x56200-13 shake door kit, 1/x56200-14 soft serve door kit, 1/x56200-15 syrup valve kit, 1/048260 o-ring removal tool. 000 *…

-

Page 22

21 x44127 brush kit assembly (see figure 12) item part no. Description qty. Function warr. Class 1 013071 black bristle brush 1 used to clean rear shell bearing and mix pump drive hub. 000 2 013072 double end brush 1 used to clean o-rings, holes in metal parts, piston grooves, mix inlet tube, mix in…

-

Page 23

22 beater door assembly — shake side (see figure 13) item part no. Description qty. Function warr. Class 1 032560 seal-drive shaft 1 provides seal from product inside freezing cylinder to internal areas of freezer. 000 2 050985 shaft-beater 7 qt. Fluted blade 1 connects beater assembly to gear unit….

-

Page 24

23 beater door assembly — shake side figure 13.

-

Page 25

24 beater door assembly — soft serve side (see figure 14) item part no. Description qty. Function warr. Class 1 x56421-1 handle a.-draw 1 operational component of the draw valve assembly. 103 2 055989 nut-stud 4 tightening mechanism to secure freezer door to freezing cylinder. 103 3 x57332-ser door …

-

Page 26

25 beater door assembly — soft serve side figure 14.

-

Page 27

26 x53800-brn/tan syrup pump (see figure 15) item part no. Description qty. Function warr. Class 1 x36576-tan x36576-brn plunger a. 1 used to dispense toppings. Nnn 1a 032762-tan 032762-brn knob-plunger 1 holds plunger assembly in place. Tan and brn indicate the hot caramel and hot fudge toppings. 1…

-

Page 28

27 x53800-brn/tan syrup pump figure 15.

-

Page 29

28 059088 tray-parts-shake side figure 16 item part no. Description 1 x50958 beater a.-7 qt. 2 041103 blade-scraper-16” 3 050985 shaft-beater 7 qt. 4 032560 seal-drive shaft 5 055989 nut-stud 6 053890 o-ring -syrup port 11mm id green 7 053867 plug-syrup port 8 034054 spinner 9 x59331 blade a.-spinne…

-

Page 30

29 059087 tray-parts-soft serve side figure 17 item part no. Description 1 x56421-1 handle a.-draw 2 055819 pin-pivot 3 050348 bearing-front 4 055989 nut-stud 5 014402 o-ring (draw valve) 6 048926 gasket (freezer door) 7 x55820 valve a.-draw 8 x57332-ser door a.-w/baffle item part no. Description 9 …

-

Page 31

30 056525 tray-parts-pump-simplified figure 18 shake side item part no. Description 1 044641 clip-mix pump retainer 2 057944 cylinder-pump- hopper-shake 3 x55450 pin a.-retaining 4 053526 piston 5 044731 pin-cotter 6 020051 o-ring 2-1/8” od- red 7 056873-xx cap-valve 8 053527 gasket-simplified pump …

-

Page 32

31 important to the operator figure 19 item description function 1 keypad-shake used for selecting operating functions on the shake side of the machine. 2 display-vacuum fluorescent menu (vfd) screen which displays menu options and notifies operator if a fault is detected. 3 keypad-menu (entry/exit)…

-

Page 33

32 symbol definitions to better communicate in the international arena, the words on many of our operator keys have been replaced by symbols to indicate their functions. Your taylor equipment is designed with these international symbols. The following chart identifies the symbol definitions. = auto …

-

Page 34

33 heat mode symbol when the heat mode symbol is illuminated, the freezer is in the process of a heat cycle. The heat mode symbol may be selected to start a heat cycle following a freezer soft lock condition. For some international models, the heat symbol can be selected to manually start a heat cyc…

-

Page 35

34 shake fill level adjustment the portion control sensor located under the cup holder can be adjusted to fill the cup to the desired level. If the fill level is too low, or the cup is overfilling, it may be necessary to adjust the sensor position. (see figure 22.) figure 22 1. Using a crescent wren…

-

Page 36

35 4. Fill the topping containers with topping. Place the caramel and fudge topping containers in the heated wells. Place the remaining two topping containers in the unheated wells. Cover the containers. 5. Sanitize the two topping ladles and place in the cold topping containers. 6. Fill the cup dis…

-

Page 37

36 5. Fill the squeeze bottle with sanitizing solution. With a pail beneath the door, insert the tube end of the squeeze bottle into the syrup port, and squeeze the bottle firmly. This action will force solution out of the adjacent port and down around the spinner. This procedure should be performed…

-

Page 38

37 14. Install the duckbill valve into the syrup nose fitting with the flat end aligned with the open slot in the syrup nose fitting. Note: replace the duckbill valve if it is damaged or extends past the syrup nose fitting slot. (see figure 29.) figure 29 15. Install the syrup nose fitting onto the …

-

Page 39

38 21. Touch the auto symbol or the optional flavor symbol to scroll the arrow to syrup prime. (see figure 33.) unflavored draw syrup calibration > syrup prime exit figure 33 22. Touch the calibration symbol to enter the syrup prime mode. (see figure 34.) syrup prime select a flavor press to clear f…

-

Page 40

39 30. When ready to resume normal operation, touch the auto symbol . (see figure 37.) the control has a feature in the manager’s menu to enable or disable the auto start feature. When auto start in enabled, the machine will automatically exit the standby mode and start both sides in the auto mode a…

-

Page 41

40 once this rate is set, the correct amount of syrup will be blended with the shake base regardless of the size of shake served. Please note that syrup calibration is critical when changing the promotional 4th flavor syrup. Calibration procedure syrup lines must be properly primed with syrup to eli…

-

Page 42

41 5. To calibrate the syrup dispensing rate, hold the small portion of the calibration cup under the valve for the flavor to be calibrated. Touch the corresponding flavor select symbol to activate the syrup pump and start the flow of syrup. When the syrup level measures one ounce, touch the same fl…

-

Page 43

42 8. Touch the auto symbol or the optional flavor symbol to scroll the arrow to syrup prime. (see figure 47.) unflavored draw syrup calibration > syrup prime exit figure 47 9. Touch the calibration symbol to enter the syrup prime mode. (see figure 48.) syrup prime select a flavor press to clear fig…

-

Page 44

43 5. Place the restrictor cap, front drip tray, shake cup holder and splash shield on a clean, dry surface to air-dry overnight or until the heating cycle is complete. 6. Prepare a small amount of mcd sanitizer (hcs) solution. Use one packet in 2.5 gallons (9.5 liters) of water (100 ppm). 7. Saniti…

-

Page 45

44 13. Fill the squeeze bottle with cleaning solution. With a pail beneath the door, insert the tube end of the squeeze bottle into the syrup ports, and squeeze the bottle firmly. This action will force solution out of the adjacent port and down around the spinner. This procedure should be performed…

-

Page 46

45 soft serve side this procedure must be done at the close of business. Important: the level of mix in the mix hopper must be above the mix low probe. (the mix low light must not be on.) note: if the brush clean counter display has counted down to one day, do not add mix. The machine must be disass…

-

Page 47

46 10. Remove, clean and reinstall the long drip pan through the front panel. (see figure 60.) figure 60 11. Remove, clean and reinstall the two short drip pans in the rear panel. 12. Remove, clean and reinstall the two notched drip pans in the left and right side panels. (see figure 61.) figure 61 …

-

Page 48

47 scheduled maintenance — syrup system syrup pump tube removal 1. Remove the syrup feed tubes from the syrup containers. Wipe the outside of the feed tubes with a clean, sanitized towel. For syrup bag system: disconnect the syrup bag fitting from each bag. 2. Remove the syrup containers and the pum…

-

Page 49

48 pump tube installation 1. Lubricate the o-rings on the syrup line fittings with taylor lube hp. Figure 64 2. Press the fittings into the new pump tube. 3. Install the clips into their respective collars. 4. Using your hands, rotate the pump rollers so they are in the 10 and 2 o’clock position. 5….

-

Page 50

49 15. Install the duckbill valve into the syrup nose fitting, with the flat end aligned with the open slot in the syrup nose fitting. Note: replace the duckbill valve if it is damaged or extends past the syrup nose fitting slot. (see figure 29.) figure 65 16. Install the syrup nose fitting onto the…

-

Page 51

50 syrup topping pump syrup topping pump disassembly before the first use, and after use weekly, disassemble and clean the pump. 1. Flush and rinse the pump in a container of warm water. Place the lower end of the pump into the water container. Operate the pump until only warm water flows from the d…

-

Page 52

51 8. Remove the seal o-ring from the seal. (see figure 72.) figure 72 9. Remove the discharge tube lock nut by turning it counterclockwise. Remove the discharge lock nut from the discharge tube. (see figure 73.) figure 73 10. Remove the lid by sliding it off the discharge tube. 11. Remove the cylin…

-

Page 53

52 4. Insert the black shielded brush into the top side of the inlet valve. Scrub this area, specifically around the steel ball. (see figure 77.) figure 77 5. Insert the black shielded brush into the top side of the outlet valve. Scrub this area, specifically around the steel ball. (see figure 78.) …

-

Page 54

53 syrup topping pump assembly after pump disassembly and cleaning is complete, assemble the pump. 1. Lubricate and install the seal o-ring into the seal. (see figure 82.) figure 82 2. Install the seal assembly onto the piston end of the plunger assembly. 3. Install the washer and spring onto the pl…

-

Page 55

54 10. Lubricate and install the 1-5/16” o-ring into the valve body. (see figure 86.) figure 86 11. Install the discharge tube onto the smaller opening in the valve body by aligning the flats on the discharge tube with the locking grooves on the valve body. Push down the discharge tube until it is s…

-

Page 56

55 draining product from the freezing cylinder to drain the product from the freezing cylinders on both sides of the machine, the steps will be the same. Therefore, first drain the product from the shake side, then go back and duplicate these procedures for the soft serve side. 1. Place the heater t…

-

Page 57

56 rinsing 1. Pour two gallons (7.6 liters) of cool, clean water into the shake mix hopper. With the white hopper brush, scrub the mix hopper, mix level sensing probes and the outside of the agitator drive shaft housing. Using the double ended brush, brush clean the mix inlet hole. (see figure 91.) …

-

Page 58

57 8. Prepare 2.5 gallons (9.5 liters) of mcd sanitizer (hcs) solution. Use one packet in 2.5 gallons (9.5 liters) of water (100 ppm). Repeat steps 2 through 7 with the sanitizing solution. Repeat steps 1 through 8 for the soft serve side of the freezer. Disassembly — shake side note: failure to rem…

-

Page 59

58 10. Remove the pump drive shaft from the drive hub in the rear wall of the mix hopper. (see figure 95.) figure 95 remove the two small o-rings and one large o-ring from the pump drive shaft. Disassembly — soft serve side note: failure to remove the parts specified below for brush cleaning and lub…

-

Page 60

59 10. Remove the two short drip pans from the rear panel. Remove the two notched drip pans from the left and right side panels. Take them to the sink for cleaning. (see figure 98.) figure 98 note: if the drip pans are filled with an excessive amount of mix, it is an indication that the drive shaft …

-

Page 61

60 equipment set-up freezing cylinder assembly — shake side make sure the power switch is in the off position. Failure to follow this instruction may result in severe personal injury from hazardous moving parts. With the parts tray available for the shake side: 1. Before installing the shake beater …

-

Page 62

61 if the blades are in good condition, place each scraper blade over the holding pins on the beater assembly. (see figure 104.) figure 104 note: the holes in the scraper blade must fit over the pins to prevent damage. 4. Holding the blades on the beater assembly, insert the beater assembly in the f…

-

Page 63

62 7. Insert the spinner shaft seal into the bottom of the draw valve as far as it will go. The spinner shaft seal should fit into the seal groove located inside the draw valve cavity. (see figure 108.) 11245 figure 108 important: inspect to see that the spinner shaft seal is correctly installed in …

-

Page 64

63 11. Place the freezer door o-ring into the groove on the back of the freezer door. Lubricate the outside diameter of the front bearing. Slide the front bearing into the door hub. Note: if necessary, put two small spots of lubricant at the 10 o’clock and 2 o’clock positions on the upper portion of…

-

Page 65

64 15. Raise the locking collar of the spinner coupling and insert the spinner shaft into the cavity of the coupling until the locking collar can drop into the locked position. (see figure 116.) figure 116 16. Snap the restrictor cap over the end of the door spout and install the syrup valve retaine…

-

Page 66

65 note: to ensure the mix does not leak out of the back of the freezing cylinder, the middle section of the boot seal should be convex or extend out from the seal. If the middle section of the boot seal is concave or extending into the middle of the seal, turn the seal inside out. (see figure 119.)…

-

Page 67

66 5. Install the beater shoes. (see figure 123.) figure 123 6. Slide the beater assembly the rest of the way into the freezing cylinder. Make sure the beater assembly is in position over the drive shaft by turning the beater slightly until the beater is properly seated. When in position, the beater…

-

Page 68

67 10. Install the freezer door. Insert the baffle rod through the beater in the freezing cylinder. With the door seated on the freezer studs, install the handscrews. Tighten equally in a criss-cross pattern to insure the door is snug. (see figure 129.) figure 129 11. Install the draw handle. Slide …

-

Page 69

68 mix pump assembly 1. Inspect the rubber pump parts. O-rings and gasket must be in 100% good condition for the pump and entire machine to operate properly. The o-rings and gasket cannot properly serve their intended function if nicks, cuts, or holes in the material are present. Replace any defecti…

-

Page 70

69 7. Insert the valve cap into the hole in the mix inlet adapter. (see figure 139.) 15111 figure 139 8. Insert the mix inlet assembly into the pump cylinder. (see figure 140.) 15112 figure 140 the adapter must be positioned into the notch located at the end of the pump cylinder. 9. Secure the pump …

-

Page 71

70 13. Slide the large black o-ring and the two smaller black o-rings into the grooves on the drive shaft. Thoroughly lubricate the o-rings and shaft. Do not lubricate the hex end of the shaft. (see figure 145.) figure 145 14. Install the hex end of the drive shaft into the drive hub at the rear wal…

-

Page 72

71 6. Caution! Install the pump end of the mix feed tube and secure with the cotter pin. Failure to follow this instruction could result in sanitizer spraying on the operator. 7. Using the white hopper brush, clean the mix level sensing probes, the mix hopper, mix inlet hole, the outside of the agit…

-

Page 73

72 17. Remove the cotter pin from the pump. Stand the mix feed tube in the corner of the mix hopper. Place the cotter pin in position in the outlet fitting of the pump. Figure 152 18. Remove the restrictor cap and the syrup hole plugs. 19. Return to the freezer with a small amount of sanitizing solu…

-

Page 74

73 5. Prepare another 2.5 gallons (9.5 liters) of mcd sanitizer (hcs) solution. Use one packet in 2.5 gallons (9.5 liters) of water (100 ppm). 6. Pour the sanitizing solution into the mix hopper. 7. Brush the exposed sides of the hopper. Wait at least 5 minutes before proceeding with these instructi…

-

Page 75

74 priming — shake side note: use only fresh mix when priming the freezer. 1. With a mix pail beneath the door spout, touch any flavor select symbol to open the draw valve. Pour 2-1/2 gallons (9.5 liters) of fresh mix into the mix hopper and allow it to flow into the freezing cylinder. This will for…

-

Page 76

75 during the initializing… Language screen, the alarm will be on. If the system de- tects corrupt data during initializing, the following display will alert the operator that the control settings may have been changed (see figure 159.) service req’d nvram fault reset to defaults figure 159 once t…

-

Page 77

76 do not attempt to draw product or disassemble the unit during the heat cycle. The product is hot and under extreme pressure. In the heat cycle, the mix temperature in the hoppers and freezing cylinders must be raised to 151 _ f (66.1 _ c) within 90 minutes. When the heating phase is complete, the…

-

Page 78

77 if the machine has hard locked and an attempt is made to enter auto, the machine will enter the standby mode and display the following message. (see figure 170.) freezer locked figure 170 to restore the message that identified the rea- son for the hard lock, turn the power switch off for five sec…

-

Page 79

78 when one of these messages appears, automatic freezer operation cannot take place until the freezer is disassembled and brush cleaned, or has completed a heat treatment cycle. Select the heat symbol to start a heat cycle, or select the wash symbol to disassemble and brush clean the machine. Once …

-

Page 80

79 the sundae side will continue operation in the mode it was in when the menu was selected. However, the sundae side control keys will not be lit and are non-functional when the manager’s menu or calibration menu is displayed. The control keys for both sides are functional in the manager’s menu whe…

-

Page 81

80 the verify calibration option is used to verify the amount of syrup dispensed is within the proper specification. (see figure 180.) verify calibration select a flavor figure 180 remove the syrup valve from the dispensing door. With the line fully primed with syrup, position the syrup valve over t…

-

Page 82

81 change the time by touching the auto or optional flavor symbol with the cursor under the hour position. Move the cursor to the minutes by selecting the calibration symbol . Once the correct minutes are entered, select the calibration symbol to advance the cursor to the month. (see figure 185.) se…

-

Page 83

82 enable the auto start time by selecting the auto symbol to move the arrow up to enable. Select the calibration symbol to advance to the next screen. (see figure 190.) auto start time 00:00 change > exit figure 190 program the auto start time by selecting the auto symbol to move the arrow to chang…

-

Page 84

83 the mix level audible option when enabled will alert the operator with an audible tone when there is mix low or mix out condition. The following screen is displayed upon selecting this option. (see figure 195.) mix level audible > enable disable figure 195 disable the audible tone feature by sele…

-

Page 85

84 faults occurring entering a heat treatment cycle power switch off — the power switch is off. Auto or stby off — the control was not in auto or standby. Mix out failure — a mix out condition was present. No heat cycle tried — the auto heat time was set to attempt a heat cycle more than 24 hours af…

-

Page 86

85 the heat cycle data screen contains a record of up to 366 heat treatment cycles. The most recent heat cycle data will be shown first. Each heat cycle record has three screens. The first screen displays the month and day of the heat cycle, the start time and end time, and the fault description. Th…

-

Page 87

86 listed below are variable failure code messages which could appear on line 2. Ht heat time failure mix temperature did not rise above 151 _ f (66.1 _ c) in less than 90 minutes. Cl cool mode failure mix temperature in the hopper and freezing cylinder did not fall below 41 _ f (5 _ c) in less than…

-

Page 88

87 the current conditions screen provides the viscosity readings for the product when the side is running and hopper and barrel temperatures for both sides of the machine. The left column displays the readings for the shake side and the right column displays the sundae side readings. The bottom line…

-

Page 89

88 tro uble s h o o t in g g ui de p robl e m sh ake sid e p roba bl e c a u s e so ft serve s id e p roba bl e c a u s e eit h er sid e p roba bl e c a u s e c o rr ect ive a ct io n soft lo c k m e s s age appear s o n d isp la y an equi pm ent faul t has oc c u rr ed. D e ter m ine reas on the fa…

-

Page 90

89 p robl e m sh ake sid e p roba bl e c a u s e so ft serve s id e p roba bl e c a u s e eit h er sid e p roba bl e c a u s e c o rr ect ive a ct io n n o pr oduc t is bei ng d i d low on m ix . T h e m ix ou t light is on. Add m ix to the m ix hopper . R etur n to a u t o m ode. G di s pens ed. Th…

-

Page 91

90 p robl e m sh ake sid e p roba bl e c a u s e so ft serve s id e p roba bl e c a u s e eit h er sid e p roba bl e c a u s e c o rr ect ive a ct io n t h e p roduc t is too s oft. T o o m uc h s y rup — 1 fl o z (3 0 m l) in 5 s e c onds . F or t ri p le t h ic k s hak e s y rup: 1 oz (3 0 m l) ± …

-

Page 92

91 p robl e m sh ake sid e p roba bl e c a u s e so ft serve s id e p roba bl e c a u s e eit h er sid e p roba bl e c a u s e c o rr ect ive a ct io n t h e p roduc t is to o th ick. N o t enough s y rup — 1 fl o z (3 0 m l) in 5 s e c onds . F or t ri p le t h ic k s hak e s y rup: 1 oz (3 0 m l) …

-

Page 93

92 p robl e m sh ake sid e p roba bl e c a u s e so ft serve s id e p roba bl e c a u s e eit h er sid e p roba bl e c a u s e c o rr ect ive a ct io n pr oduc t is co lle ct in g o n to p of the d ra w l inadequate lubr ic ati o n of s p inner s haft o r s eal . Lubr ic ate p roper ly . Va lve . Sp…

-

Page 94

93 p robl e m sh ake sid e p roba bl e c a u s e so ft serve s id e p roba bl e c a u s e eit h er sid e p roba bl e c a u s e c o rr ect ive a ct io n th e d ri ve sh a ft is s tuc k in the dr iv e c oupl ing. M ix and lubr ic ant co lle ct e d in d rive c oupl ing. Br us h c lean the rear s hel l …

-

Page 95

94 p robl e m sh ake sid e p roba bl e c a u s e so ft serve s id e p roba bl e c a u s e eit h er sid e p roba bl e c a u s e c o rr ect ive a ct io n n o c ontr o l p a n e l fu n c ti o n s m a c h in e is unpl ugged. P lu g in to wa ll re ce p ta c le . P a n e l fu n c ti o n s w it h pow er sw…

-

Page 96

95 p robl e m sh ake sid e p roba bl e c a u s e so ft serve s id e p roba bl e c a u s e eit h er sid e p roba bl e c a u s e c o rr ect ive a ct io n th e d ra w v a lve is not c los ing. Th e d ra w v a lve wa s not al igned w it h the ac tuator br ac k e t w hen the fr eez er door w a s in st a …

-

Page 97

96 p robl e m sh ake sid e p roba bl e c a u s e so ft serve s id e p roba bl e c a u s e eit h er sid e p roba bl e c a u s e c o rr ect ive a ct io n sy ru p c annot b e ca lib ra te d o r i i t t t h e pum p tube has c o llaps ed. R epl ac e pum p tube. In c ons is tent ca lib ra ti o n readi ngs…

-

Page 98

97 p robl e m sh ake sid e p roba bl e c a u s e so ft serve s id e p roba bl e c a u s e eit h er sid e p roba bl e c a u s e c o rr ect ive a ct io n sy ru p c onti nues to fl o w a ft e r ai r in s y rup line. F o llo w s y rup pr im e p ro c edur e. To fl o w a ft e r dr aw in g a s hak e. Du ck…

-

Page 99

98 parts replacement schedule part description every 3 months every 6 months annually scraper blade-shake x scraper blade-soft serve x drive shaft seal x freezer door o-ring-shake x freezer door gasket-soft serve x front bearing x front beater shoes-soft serve x draw valve o-ring x spinner shaft sea…

-

Page 100

99 ordering/service information taylor distributor: address: phone: date of installation: data plate the data plate provides necessary information that the operator should record and refer to when calling for parts or service. The data plate is located on the rear or left side panel of the freezer. …

-

Page 101

100 wiring diagram 3 ph. 059480-33 rev. 4/05.

-

Page 102

101 wiring diagram 3 ph. 059480-58 rev. 4/05.

-

Taylor C602 42 Systems, Controls and Operations Model C602 Adjustable Draw Handle This unit features an adjustable draw handle to provide the best portion control, giving a better, consistent quality to your product and controlling costs. The draw handle should be adjusted to provide a flow rate of 5 to 7-1/2 oz. (142 to 213 g.) of product by weight per 10 seconds. To INCREASE the flow rate, turn the screw CLOCKWISE, and COUNTER- CLOCKWISE to DECREASE the flow rate. (See Figure 86.) Figure 86

-

26 Systems, Controls and Operations Model C602 STANDBY TEMPERATURE The STANDBY TEMPERATURE option allows the service technician to adjust the freezing cylinder temperature in the Standby mode. In Standby, the machine will cycle the compressor (and beater) on if the temperature of the product in the freezing cylinder rises above the setpoint. The compressor will cycle off when the temperature of the product in the freezing cylinder drops 4°F(2.2°C) or more below the set point. (See Figure 53.) STANDBY TEMP L CUT

-

Taylor C602 104 Parts Model C602 040608 Accessories Figure 129

-

88 Parts Model C602 040608 Beater Doo r Assembly — Shake Side ITEM DESCRIPTION PART NO. 1 Seal -Drive Shaft 032560 2 Shaft-Beater 7 Qt. Fluted Blade 050985 3 Blade -Scraper-16” 041103 4 Bearing-Door Front 1.390 OD 055605 5 Beater A.-7 Qt. Fluted Blade X50958 6 O-Ring 6” — Freezer Door 033493 7 Door A. -Shake Side X55825SER2 8 Nut -Stud-Short 055989 9 O-Ring -Syrup Port 11mm ID x 2mm Green 053890 ITEM DESCRIPTION PART NO. 10 Plug-Syrup Port 053867 11 Retainer-Syrup Valve 054554 12 O -Ring — 1-1/16 OD x .139 W (Draw Valve) 020571-1 13 Seal-Spinner S

-

Taylor C602 100 Parts Model C602 Dec Plate Assembly — X55963 Figure 125 ITEM DESCRIPTION PART NO. 1 PLATE-DEC 056131 2 PCB A.-INTERFACE X55960 -SER 3 INSULATOR-PCB-INTERFACE 057168 ITEM DESCRIPTION PART NO. 4 SCREW-6-32 X 3/8 BIN. HD 002201 5 CABLE-RIBBON-14C-3”L 056864

-

Taylor C602 + Available Separately 114 Parts List Model C602 040608 DESCRIPTION PARTS UPDATE REMARKSWARR. CLASS QTY.PART NUMBER LABEL -RESET-MIX PMP 022723 2 000 LABEL -RESET-MIX PMP 044452 2 000 LABEL -SW-POWER -OFF/ON-SYMBOLS 052632 1 000 LABEL -WARN-COVER 051433 5 000 LABEL -WARN-LOCK-SHK-ENG/SPN 053760 1 000 LATCH-DOOR-MAGNETIC PUSH OPEN 058630 1 103 LID-SYRUP JAR 042706 2 103 LINE A.-SYRUP DOOR *C602* X56652 4 103 TO SHAKE DOOR/ WIDE SLOT SYRUP NOSE +FERRULE-.625 ID NP BRASS 053036 8 000 +FITTING-BARB Q.D. .250 ID 056675 4 103 +FITTING-SY

-

Taylor C602 103 Model C602 Parts 040608 Sensor Holder Assembly — X55980 Figure 128 ITEM DESCRIPTION PART NO. 1 BRACKET A.-SENSOR X56341 2 SCREW-ADJUSTMENT 5/16 -18 051574 3 SCREW -10-32 X 9/16 DOG 038981 4 SENSOR A.-PYROELECTRIC X59268 ITEM DESCRIPTION PART NO. 5 HOLDER-MTG-SENSOR PROBE 056503 6 NUT-5/16-18 LOCK SS 043072 *7 PCB A.-PYRO X59073-SER *8 STANDOFF 1/2” 040280-007 *NOT INCLUDED W/X55980 SENSOR HOLDER ASSY.

-

Taylor C602 66 Troubleshooting Model C602 General Troubleshooting (Cont ’d.) PROBLEM CAUSE REMEDY 28. “Compressor on too long” fault message. a. Inadequate pump operation. a. Check pump operation. Assemble pump according to instructions in the operator’s manual. b. Draw rate set too fast. b. Set the draw rate at 5 — 7-1/2 oz. (142 213 g) of product per 10 seconds. c. Inadequate air flow. c. Provide 3” (76 mm) air space around sides. d. Faulty blower baffle. d. Repair or replace blower baffle. e. Inadequate AXV settings. e. Set AXV at proper setting. (See “Running Specifications”.) 29. Symbol selection is dela

-

20 Systems, Controls and Operations Model C602 AUTO HEAT TIME The AUTO HEAT TIME screen allows the manager or service technician to set the time of day in which the heat treatment cycle will start. (See Figure 33.) AUTO HEAT TIME 00:00 Change >Exit Figure 33 Note: Do not advance the Auto Heat Time setting except on the day the unit is brush cleaned. Increasing the time between heat cycles will cause the machine to soft lock if the start of the cycle does not begin within 24 hours fr

-

Taylor C602 Model C602 059480-33 Rev. 6/04

-

Taylor C602 48 Systems, Controls and Operations Model C602 Interface Boards Both interface boards are the same for the shake and soft serve side. Ribbon cables provide the communication path between the UVC3 and the interface boards. A 16 VAC transformer supplies the power for the interface boards at Terminals A and B. Each board has a 5 VDC output terminal block. Line voltage is connected to the interface boards (L1 and L2) to operate components in the machine on command. There are four sets of pins (W2,W3,W4,W5) on each interface board. The pins on the soft serve board are

-

Model C602 059480-58 Rev. 6/04

-

Taylor C602 + Available Separately 116 Parts List Model C602 DESCRIPTION PARTS UPDATE REMARKSWARR. CLASS QTY.PART NUMBER +LABEL -INST-SYRUP LABEL RESET 055810 2 000 +PLUG-DRAIN-WYOTT 023953-5 3 103 +THERMOSTAT -ADJ-SNAP ACTING 049993 2 103 PCB A. -PYRO *C602* X59073 -SER 1 212 SENSOR PCB A. -INTERFACE-HT-SH-C602 X59076-SER 1 212 +PCB A. -PERSONALITY C602 SHAKE X59072-SER 1 212 +PCB A. -HEAT TREAT INTF BASE-UK X53451-SER 1 212 PCB A. -INTERFACE-HT-SS-UK X53453-SER 1 212 +PCB A. -PERSONALITY-HT-SS X46904-SER 1 212 +PCB A. -HEAT TREAT INTF BASE-UK X53451-SER 1 212 PCB A. -UVC3 X59210 -SER 1 212 K3104504/UP 176

-

Taylor C602 97 Model C602 Parts X58450 Syrup Line Assembly — Syrup-In-Bag Option Figure 123 ITEM DESCRIPTION PART NO. 1 O-Ring-1/2 OD x .070 024278 2 Fitting -Male 054526 3 Ferrule-.625 ID NP Brass 053036 4 Coupling-QD Female 3/8 Barb 058451 ITEM DESCRIPTION PART NO. 5 Coupling-QD Male 1/4 Barb 058452 6 Tube-Vinyl 3/16 ID x 1/16 Wall 020940 -8 7 Hose-Beverage 3/8 ID 053052-36

-

Taylor C602 39 Model C602 Systems, Controls and Operations Glycol Path (Rear View) Figure 84

-

54 Systems, Controls and Operations Model C602 040608 Draw Soleno id (059462) The Draw Valve Solenoid has a 187 Volt DC coil. The coil is energized by direct current supplied from the rectifier board passing through the Pull and Hold Relays to open the draw valve. The Pull and Hold coil windings are powered to raise the draw valve. The Pull windings are only momentarily powered to raise the plunger. The Hold windings remain powered to hold the draw plunger in the raise

-

67 Model C602 Troubleshooting Air Mix Pump System Troubleshooting PROBLEM PROBABLE CAUSE REMEDY 1. Air/mix pump will not operate in the AUTO mode when the draw valve is opened. a. Pump drive is out on reset. a. Allow the unit to cool and press the reset button. b. Malfunctioning interface board. b. Replace interface board. c. Faulty pump motor. c. Replace motor. d. Faulty connection or draw switch. d. Check connections or replace switch. 2. Piston travels back and forth, but the product is no

-

Taylor C602 53 Model C602 Systems, Controls and Operations Shake Draw Solenoid Electrical Circuit

-

Taylor C602 13 Model C602 Systems, Controls and Operations Heat Cycle The HEAT symbols on the control panel are illuminated throughout the heat treatment cycle. Two warning messages will be displayed on the screen. “DO NOT DRAW” will be displayed when the mix temperature is below 130°F (54.4°C). (See Figure 9.) L: DO NOT DRAW R: DO NOT DRAW Figure 9 When the temperature of the mix is above 130°F (54.4°C) the screen will display a message indicating that HOT PRODUCT is in the machine. (See Figure 10.) L: HOT PRODUCT R: HOT PRODUCT Figure 10 DO NOT attempt to draw product or disassemble the unit during th

-

Taylor C602 16 Systems, Controls and Operations Model C602 If the following screen appears, a soft lock has occurred during the heat treatment cycle. (See Figure 17.) HEAT TREAT FAILURE FREEZER LOCKED HEAT FOR HEAT CYCLE WASH TO BRUSH CLEAN Figure 17 A soft lock can also occur any time during operation when the hopper or freezing cylinder temperature rises above 59°F (15°C), or the temperature rises and remains above 41°F(5°C) for more than four hours. If a PRODUCT OVER TEMPERATURE condition occurs during operation, the following

-

81 Model C602 Parts Main Exploded View Parts List ITEM DESCRIPTION PART NO. 1 SHELL A. -INSULATED X55976 1a BEARING-REAR SHELL 031324 1b WASHER -BEARING LOCK 012864 1c NUT-BRASS BEARING 028991 1d GUIDE-DRIP SEAL 028992 2 COUPLING-DRIVE 3/4 HEX 012721 3 SENSOR A. -EVC X44951 4 COUPLING A.-TORQUE-SHAK X54722 5 GEAR A.*REDUCER 4.21:1 021286 -SER 6 PULLEY -AK64-5/8 007538 7 MOTOR -REDUCER 108RPM 044723-27S 8 PULLEY -2AK74 -5/8 027822 9 MOTOR -REDUCER 32 RPM 036955-34S 10 BELT-AX31 041575 11 BELT-AX33 024396 12 BOX-SPLICE 056677 * COVER-SPLICE BOX 056678 13 MOTOR A.-AGITATOR X55971-27 13

-

Taylor C602 12 Systems, Controls and Operations Model C602 Heat Mode Symbol When the HEAT MODE symbol is illuminated, the freezer is in the process of a heat cycle. The heat mode symbol may be selected to start a heat cycle following a freezer soft lock condition. For some International models, the heat symbol can be selected to manually start a heat cycle at any time. Brush Clean Countdown — Displays the number of days before the next brush cleaning is required. When the display has counted down to “1”, the machine must be disassembled and brush cleaned within 24 hours. Power Up

-

Table of Contents Model C602 Table of Contents — Page 2 Section 4: Parts 77…………………………………………………… Parts Warranty Explanation 78………………………………………… Main Exploded View 80……………………………………………… Operator Parts Identification 83………………………………………… Front View 85……………………………………………………… Beater Door Assembly — Shake Side 87…………………………………. Beater Door Assembly — Soft Serve Side 89…..

-

Taylor C602 102 Parts Model C602 Glycol Heater Assembly — X55965-27 Figure 127 ITEM DESCRIPTION PART NO. 1 SCREW-1/4-20 X 1-1 /4 SOCKT 015350 2 NUT-1/4-20 MF LOCK 017523 3 ADAPTOR-1/4 MP X 5/16 BARB 047326 4 RELIEF -STRAIN 7/8” HOLE 006968 5 TEE-1/4 FPT X 1/4 MPT 021277 6 HOSE-RUBBER 5/16 ID X 9/16 047340-16 7 HEATER A.-GLYCOL -4500 X47395-SER 8 ADAPTOR-5/16 FS X 5/16 BARB 047958 9 CLAMP-HOSE 35/64 STEPLES 047344 ITEM DESCRIPTION PART NO. 10 HOSE -RUBBER 5/16 X 9/1 6 047340-4 11 ARMAFLEX 1/2 ID X 3/8 WALL 020897-4 12 ELBOW-1/4 MP X 5/16 BARB 047327 13 VALVE -SOLENOID 3-W 1/4 FPT 037954-27 14 CONNECTOR -BX 3/8 STR2 01456

-

27 Model C602 Systems, Controls and Operations GLYCOL TEMPERATURE The GLYCOL TEMPERATURE allows the Service Technician to adjust the glycol temperature used to control the glycol heater in the HEAT and HOLD phases of the Heat Treatment Cycle. When the glycol temperature falls 6°F(3.3°C) or more below the set point, the glycol heater is activated. When the glycol temperature rises above the set point, the heater is de- activated. The factory glycol temperature setting is 178°F(81°C). (See Figure 57.) GLYCOL TEMPS HEATING : 178.0 CURRENT : 41.0 > Next Figure 57 Adjust the temp

-

Taylor C602 69 Model C602 Troubleshooting Peristaltic Syrup System Troubleshooting (Cont’d.) PROBLEM CAUSE REMEDY 4. Flavor carry -over. a. There is air in the syrup line. a. Prime the syrup line. b. The Whitespot Setting is incorrect. b. Adjust the Whitespot Setting in the Service Menu. Recommended setting: 0.1 — 0.2 for standard shakes and 0.4 for Triple Thick Shakes. c. The pump motor reverse time is set too low. c. Adjust the pump motor reverse time in the Syrup Motor Setup menu. d. The reverse relay does not reverse th

-

35 Model C602 Systems, Controls and Operations Timers Two Minute Stir Cycle If either side of the machine is in the STANDBY mode, the beater motor for that side will turn on for six seconds every two minutes. If any hopper is above the cut- in temperature, the beater stir cycle timer is activated. Soft Serve — If the machine is in the HEAT mode, this two minute stir cycle will continue until the freezing cylinder temperature rises above 135_F (57_C). If the machine is in the AUTO mode or the COOL phase of the Heat Treat

-

Taylor C602 115 + Available Separately Model C602 Parts List DESCRIPTION PARTS UPDATE REMARKSWARR. CLASS QTY.PART NUMBER +CAPACITOR-RUN .8UF/400V 039482 1 103 MOTOR-GEAR ULTIMATE SYRUP 058725 4 103 MOTOR-REDUCER 108RPM-SHK-HT 044723-27 1 212 SHAKE +OVERLOAD-TI#2BM-28B0R-KG16 -68 042005 -34 1 103 +RELAY-MTR START TI#4CR-2-645 042007 -34 1 103 +NUT -OVERLOAD RESET 045026 1 000 MOTOR-REDUCER 32 RPM-HPR PUMPM 036955-34 1 212 SOFT SERVE +CAPACITOR-START 47-56UF/220TO 037251-34 1 103 +OVERLOAD-TI #2BM-20V9R-KK20-71 044464 1 103 +RELA

-

Taylor C602 98 Parts Model C602 Control Assembly — X55966-33 Figure 124

-

Taylor C602 43 Model C602 Systems, Controls and Operations Control Overview Figure 87

-

41 Model C602 Systems, Controls and Operations Portion Control (Shake) The portion control sensor, located in the cup bracket, is a pyro-electric sensor which responds to temperature changes of any kind. When the draw valve is opened (during the AUTO mode) and the product level in the cup reaches the sensor, it will recognize a temperature change. The control board then automatically closes the draw valve. Portion Control Operation The interface board receives 16 VAC from the transformer and conver

-

31 Model C602 Systems, Controls and Operations CALIBRATE PROXIMITY SWITCH This option allows the service technicians to adjust the mounting of the proximity switch. This procedure must be performed while the machine is fully assembled and properly primed. In addition, the product temperature must be above 32°F(0°C) If the temperature is below 32°F(0°C), the Temp. Error screen will be displayed. (See Figure 75.) CAL PROXIMITY SW ERROR TEMP MUST BE GREATER THAN 32.0 F >Exit Figure 75 When the barrel temperature is above 32°F(0°C) the Cal Proximity screen will be displ

-

84 Parts Model C602 040608 Operator Part s Ident ificatio n ITEM DESCRIPTION PART NO. 1 Cover-Hopper*Black* 053809-1 2 Agitator Assembly X44797 3 Pin-Retaining Hopper Cover 043934 4 Pan -Drip-Rear 8 -3/4” L (22.2 cm) X56003 5 Panel-Rear -Upper 055958 6 Guide A.- Drip Pan Mix Pump X48228 7 Panel-Rear -Lower 055959 8 Pan -Drip-Side 12-3/4” L (32.4 cm) X56005 9 Trim-Corner-Rear Right Side 056692 9 Trim-Corner-Rear Left Side 056693 10 Caster-4” 044106 11 Screw-1/4 — 20 x 3/8 011694 ITEM DESCRIPTION PART

-

Taylor C602 79 Model C602 Parts Notes:

-

Taylor C602 30 Systems, Controls and Operations Model C602 040608 CAL SYRUP TIME This option allows the service technician to adjust the Calibrate Syrup Time which determines the flow rate of the syrup. Example: 1 oz.(28 g) syrup dispensed in 5 seconds. The recommended Cal Syrup Time for standard shakes is 5.0 seconds and is 7.0 seconds for Triple Thick Shakes. The following screen is displayed by selecting this option: (See Figure 70.) CAL SYRUP TIME TIME : 5.0 SEC Figure 70 Select the AUTO symbol to increase the time setting or the OPTIONAL FLAVOR symbol to decrease the setting. Select the CALIBRATION sy

-

+ Available Separately 124 Parts List Model C602 DESCRIPTION PARTS UPDATE REMARKSWARR. CLASS QTY.PART NUMBER BOX-TOOL 15 INCH PLASTIC 058669 1 000 BOTTLE-WASH-PLASTIC 044818 1 000 50HZ BELT -AX31 041575 1 000 SHAKE BELT -AX34 025729 2 000 SOFT SERVE BLOCK-TERMINAL 4P-L1,L2,L 039424 2 103 BLOCK-TERMINAL 7P GREEN 024156 2 103 CAP-VALVE BODY SHAKE 056873-12 1 103 INCLUDED WITH ACCESSORIES CAP-VALVE BODY SHAKE 056873-16 1 103 INCLUDED WITH ACCESSORIES CAP-VALVE BODY SS 056874-12 1 103 INCLUDED WITH ACCESSORIES CAP-VALVE BODY SS

-

Taylor C602 109 + Available Separately Model C602 Parts List DESCRIPTION PARTS UPDATE REMARKSWARR. CLASS QTY.PART NUMBER COVER-HOPPER *BLACK* 053809-1 2 103 +PIN-RETAINING-HOPPER COVER 043934 2 103 COVER A.-SENSOR *C602* X56882 1 103 PORTION CONTROL COUPLING A.-DRIVE-SPINNER X20329 1 103 COUPLING A.-TORQUE -SHAKE*4SPR* X54722 1 103 +COUPLING-TORQUE-DRIVE TTS 054723 1 103 COUPLING-TORQUE-LOAD-SQ *TTS* 054724 1 103 LABEL -IDENTIFICATION-GREEN 049285 -GRN 1 000 +PIN-COUPLING-TORQUE 039453 4 103 +PIN-STOP-TORQUE COUPLING .792 054725 4 103 +SCREW-5/16-18X3/8 ALLEN SET 025376 2 000 +SCREW-SHOULDER 3/16DX1/2L-SS 039455 4 000 +SP

-

+ Available Separately 108 Parts List Model C602 DESCRIPTION PARTS UPDATE REMARKSWARR. CLASS QTY.PART NUMBER BLOCK-TERMINAL 3P-L1,L2,L3 039423 2 103 BLOCK-TERMINAL 7P GREEN 024156 1 103 BLOWER A. X53725-27 1 103 +CLIP-SCREEN-BLOWER 053730 4 103 HOUSING-BLOWER-6 POLE 053728 1 103 +MOTOR-FAN 208-230V 50/60 HZ 053481-27 1 103 +SCREEN-BLOWER 053729 1 103 +WHEEL-BLOWER 053726 1 103 CABINET A.-ULT SYRUP *C602* X55984 1 103 CABLE A.-LOW VOLTAGE *C602* 056750 1 103 CABLE-4 COND -#22 SHIELDED 039309-50 1 103 POWER CABLE IF-UC (BULK P/N R600309) CABLE-RIBBON-10C-34

-

4 Introduction Model C602 Model C602 Specifications Freezing Cylinders Shake Side: One, 7 quart (6.6 liter) Soft Serve: One, 3.4 quart (3.2 liter) Mix Hopper Two, 20 quart (18.9 liter). Refrigerated to maintain mix below 41°F (5°C). Beater Motor Shake: 1.0 HP Soft Serve: 1.5 HP Refrigeration System Shake: 11,000 BTU/hr Soft Serve: 9,500 BTU/hr Refrigerant: R404A (BTU’s may vary depending on compressor used.) Main Compressor: Air Cooled Units: Shake: 54 oz (1,531 g) of R404A Soft Serve: 46 oz (1,304 g) of R404A Water Cooled Units: Shake: 48 oz (1

-

Taylor C602 82 Parts Model C602 040608 Main Exploded View Parts List (Co nt’d.) ITEM DESCRIPTION PART NO. 62 STUD-NOSE CONE 055987 63 GUIDE A.-DRIP PAN CENTER X55972 64 SWITCH -TOGGLE-DPDT 024295 65 SWITCH A. -DRAW X33322 66 PANEL A. -FRONT X55981 66a RAIL A.-SYRUP X56287 67 HOLDER A.-SENSOR-ADJ X55980 68 PLATE A.-MOUNT-PORT. X55978 69 HOLDER-CUP-SHAKE-3.906 056008 70 SCREW-10-3 2 X 1/2 TRUSS HD 037734 71 PCB A.-PYRO X59073 -SER 72 FITTING-PANEL MT QD .250 ID 056674 73 BRACKET-RECTIFIER 059481 74 COUPLING A. -DRIVE-SPINNER X20329 75 COUPLING-FLEXIBLE W/SCR 020108 76 SOLENOID-DRAW VALVE-S

-

+ Available Separately 120 Parts List Model C602 DESCRIPTION PARTS UPDATE REMARKSWARR. CLASS QTY.PART NUMBER SWITCH-REED*DOOR INTERLOCK*68” 056771 1 103 SHAKE SWITCH-REED *DOOR INTERLOCK*97 059071 1 103 SOFT SERVE SWITCH-TOGGLE-DPDT*VDE APPROVD 054809 1 103 DEC PLATE +GUARD-POWER SWITCH 034830 1 103 FRONT PANEL TANK-GLYCOL 1.5QT-PLASTIC 047314 1 103 TRAY A. -DRIP-SYRUP CABINET X56006 1 103 TRAY-DRIP-19-5/8 L X 4-7/8 033812 1 103 TRAY-PARTS-SS SIDE C602 059087 1 000 TRAY-PARTS-SHAKE SIDE C602 059088 1 000 TRIM-CORNER-REAR -L *C602* 056693 1 103 TRIM-CORNER-REAR -R *C602* 056692 1

-

78 Parts Model C602 Parts Warranty Explanation Class 103 Parts: The warranty for new equipment parts is one year from the original date of unit installation, with a replacement parts warranty of three months. Class 212 Parts: The warranty for new equipment parts is two years from the original date of unit installation, with a replacement parts warranty of twelve months. Class 512 Parts: The warranty for new equipment parts is five years from the original date of unit installation, with a replacement parts warranty o

-

83 Model C602 Parts 040608 Operator Parts Identification Figure 113

-

Taylor C602 15 Model C602 Systems, Controls and Operations To restore the message that identified the reason for the hard lock, turn the power switch OFF for five seconds and then return the power switch to the ON position. The original message with the reason for the Hard Lock will be displayed. The FAULT DESCRIPTION can also be found in the Manager or Service Menu (See page 22.) The FREEZER LOCKED message will remain on the display until the brush clean requirements are fulfilled. The freezer must be disassembled in order to activate the five minute timer on the display screen. Once t

-

101 Model C602 Parts Torque Coupling Assembly — X54722 Figure 126 ITEM DESCRIPTION PART NO. 1 SCREW-SHOULDER 3/16DX1/2L 039455 2 LABEL-IDENTIFICATION-GRN 049285-GRN 3 COUPLING-TORQUE-LOAD 054724 4 PIN -STOP-TORQUE CPLG 054725 ITEM DESCRIPTION PART NO. 5 SPRING-3/8 OD X 3/16 GREEN 039454 6 PIN -COUPLING-TORQUE 039453 7 COUPLING-TORQUE-DRIVE 054723 8 SCREW -5/16-18 X 3/8 ALLEN 025376

-

19 Model C602 Systems, Controls and Operations RESET DRAW COUNTER The SERVING COUNTER screen is used to check or reset the number of servings dispensed from the machine. The SERVING COUNTER will automatically reset to zero when the machine is brush cleaned. (See Figure 27.) SERVINGS COUNTER LEFT RIGHT 00 > Next Figure 27 Reset the SERVING COUNTER by selecting the CALIBRATION symbol to advance to the next screen. Select the AUTO symbol to move the arrow (>

-

Taylor C602 36 Systems, Controls and Operations Model C602 14 Day Timer If the machine runs longer than 14 days without a successful brush cleaning, the machine will hard lock. Note: This timer is adjustable from 2 to 14 days. Heat Phase Timer The Heat Phase Timer times out the maximum allowable time the unit can be in the Heat Phase of the Heat Treatment Cycle (90 minutes). If the timer exceeds 90 minutes, the unit will lock-out. Hold Phase Timer This timer assures that product in the freezing cylinder and the hopper are held above 150_F (65_C) for a minimum of 30 continuous minutes. Heat Soak Timer The Heat Soak Timer prevents the HOLD phas

-

Taylor C602 105 Model C602 Parts 040608 Accessories ITEM DESCRIPTION PART NO. 1 Dispenser A.-Cone (Optional) X56121 1a Baffle-Rubber Cone 052193 2 Kit A.-Syrup Plug Kit X58474 3 O-Ring-11mm Green (Syrup Hole Plug) 053890 4 Tool -Seal Install-Remove 035460 5 Bottle-Plastic Wash 044818 6 Tool -O-Ring Removal 048260-WHT 7 Tool -Shaft-Drive -Pump-Hopper 057167 8 Cup-Divided Syrup 017203 9 Lubricant-Taylor Hi-Performance 048232 10 Pail-Mix 10 Qt. 013163 11 O -Ring — 1-11/16 OD (Draw Valve Cap) 041923 ITEM DESCRIPTION PART NO. 12 Cap A.-Valve-Draw X54704 13 Tray A.-Syrup (Syrup in Bag) X59143 14 Tank -Syrup 4 Qt. (Optional) 056673 * Kit A.-Peristalt

-

Taylor C602 23 Model C602 Systems, Controls and Operations Listed below are the variable messages that may appear. Faults Occurring While Entering a Heat Treatment Cycle POWER SWITCH OFF — The power switch is OFF. AUTO OR STBY OFF — The control was not in AUTO or STANDBY. MIX OUT FAILURE — A mix out condition was present. NO HEAT CYCLE TRIED — The Auto Heat Time was set to attempt a heat cycle more than 24 hours after the last successful heat cycle. Faults Occurring While in Heat Mode HEAT MODE FAILURE — The maximum allowable heat mode time exceeded 90 minutes. COOL MODE FAILURE —

-