-

Страница 1

Industrial Measur ement and Control HC900 Hybrid Contr oller Installation and User Guide Doc. No.: 51-52-25-107 Revision: 5 Date: 9/03[…]

-

Страница 2

ii HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Notices and Trademarks Copyright 2003 by Honeywell Revision 5 Sept. 2003 Warranty/Remedy Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact your local sales office for warranty information. If warranted goods are retu[…]

-

Страница 3

Revision 5 HC900 Hybrid Controller Installation and User Guide iii 9/03 About This Document Abstract This docum ent provides descr iptions and pro cedures for the instal lation, operation a nd maintenance of the HC900 Hybrid C ontroller hard ware. References The following list identifies all documents that may be sources of refere nce for material […]

-

Страница 4

iv HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Symbol Definitions The following table lists those symbols that may be us ed in this document and on the product to denote certain conditions. Symbol Definition This DANGER symbol indicates an imminently hazardous situation, which, if not avoided, will result in death or serious[…]

-

Страница 5

Revision 5 HC900 Hybrid Controller Installation and User Guide v 9/03 Contents Introducti on ………………………………………………………………………………… 1 Purpose ………………………………………………………………………………………………………… 1 Functional Description …….[…]

-

Страница 6

vi HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Communications In stallation ……………………………………………………….. 85 Overvi ew ……………………………………………………………………………………………………… 85 Connecting the HC900 Controller to a PC with the H[…]

-

Страница 7

Revision 5 HC900 Hybrid Controller Installation and User Guide vii 9/03 DC Input M odule …………………………………………………………………………………………. 165 AC Input Module …………………………………………………………………………………………. 166 Features Common to a ll Outpu[…]

-

Страница 8

viii HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Tables Table 1 – Descriptions of Major Com ponents (Figure 3) ……………………………………………………………….. ……………….. 7 Table 2 Simultaneous seri al port conf igurations ………………………………………………………..[…]

-

Страница 9

Revision 5 HC900 Hybrid Controller Installation and User Guide ix 9/03 Figures Figure 1 – Small HC900 Controller Conf iguration ……………………………………………………………………. ………………….. 2 Figure 2 – Expanded HC 900 Controller Configur ation (C50 CPU only) ……………………………………..[…]

-

Страница 10

x HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Figure 54 — Pathways for Up load/Dow nload Transactions ……………………………………………………………….. ………….. 114 Figure 55 — LE D In dicators ………………………………………………………………………………………..[…]

-

Страница 11

Revision 5 HC900 Hybrid Controller Installation and User Guide 1 9/03 Introduction Purpose This publication describes the Honeywell HC900 Hybrid Contro ller, and facilitates its installation, operation, and maintenan ce. This publication includes the following sections. Section Title Section Content Introduction Describes the c ontent and purpos e […]

-

Страница 12

Introduction — Functional Description 2 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Functional Description The Honeywel l HC900 Hybrid C ontroller is an integrated loop and logic controller that is design ed specifically for small- and medium -scale unit operations It comprises a set of hardware an d software m odules that c[…]

-

Страница 13

Introduction — Feature Summary Revision 5 HC900 Hybrid Controller Installation and User Guide 3 9/03 The HC900 Controller design enables users and OEMs who are adept in system integration to assemble a system t hat fits a broad range of requirem ents. Any confi guration can be readily modifi ed or expanded as requirements dictate. In initial config[…]

-

Страница 14

Introduction — Feature Summary 4 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Control Functions • Comprehensive set of Function Blocks; in cludes: − PID: Model C50 — up to 32 loops Model C30 – up to 8 loops − Setpoint P rogrammers: up t o 8; SP Profiles: pool of 99, wit h up to 50 Se gments/Profile; SP Schedulers: 1 o[…]

-

Страница 15

Revision 5 HC900 Hybrid Controller Installation and User Guide 5 9/03 Components and Architecture Overview This section pr ovides a descript ion of each of the major com ponents that can be incl uded in an HC900 Controller physical configura tion, and indic ates some of th e methods by whic h they can be com bined. Components The Honeywell HC900 Hy[…]

-

Страница 16

Components and Architecture — Components 6 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Figure 3 — Configuration with Multiple Controllers[…]

-

Страница 17

Components and Architecture — Components Revision 5 HC900 Hybrid Controller Installation and User Guide 7 9/03 Table 1 – Descriptions of Major Components (Figure 3) Key No. Component Name Description Source 1 Controller (Local) Rack Includes: Rack, Power Supply, Controller Modul e, and I/O modules Honeyw ell 2 I/O Expansion Rack (C50 CPU only) (O[…]

-

Страница 18

Components and Architecture — Hard ware Components 8 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Hardware Components This section contains general descriptions of each of the m ajor component s of the HC900 system. For environm ental specifications, refe r to the secti on on Pre-Instal lation Planning. HC900 Controller Rack […]

-

Страница 19

Components and Architecture — Hard ware Components Revision 5 HC900 Hybrid Controller Installation and User Guide 9 9/03 Rack Options Racks are availa ble in 4-slot, 8-sl ot, and 12-Slot versions. Racks are interc hangeable between the Controller rack and an IO expansion rack (C 50 CPU only) , and all three vers ions shown in Fi gure 6 are availabl[…]

-

Страница 20

Components and Architecture — Hard ware Components 10 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Controller Module The Controller Module is shown in Figure 8 with the hinged protective door open. Features at the front of the Controller Module in clude: 1 — a lithium battery (beneath cover), which is readily accessible for f[…]

-

Страница 21

Components and Architecture — Hard ware Components Revision 5 HC900 Hybrid Controller Installation and User Guide 11 9/03 Input/Output Modules Eight input/ output types are available: • Analog − Universal Anal og Input, 8-poi nt − Analog Out put, 4-point • Digital − 120/240 Vac inp ut, 16-point − 24 Vdc inp ut, 16-point − Contact inp […]

-

Страница 22

Components and Architecture — Hard ware Components 12 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Personal Computer A Personal C omputer is re quired for creating t he contro l and data acquisition strategy (configuration file) that runs in the controller, us ing the Hybrid Control Designer confi guration software . The PC c[…]

-

Страница 23

Components and Architecture — Et hernet Dev ices/Considerations Revision 5 HC900 Hybrid Controller Installation and User Guide 13 9/03 Ethernet Devices/Considerations Ethernet devic e requirements va ry with specific appli cations. Regarding intended use, however, they fall into two categories: • Component s of the Ethernet O pen Connectivity Net[…]

-

Страница 24

Components and Architecture — Et hernet Dev ices/Considerations 14 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 The Ethernet Hu bs used in the I/ O expansion networ k (C50 CPU only)a re available from Honeywell. I/O implementation requirements include: • Constructing a configu ration file, and loading it into the Controller[…]

-

Страница 25

Components and Architecture — Et hernet Dev ices/Considerations Revision 5 HC900 Hybrid Controller Installation and User Guide 15 9/03 Implem enting peer-to-peer c ommunications involves: • Interconnecti ng controlle rs with Ethernet m edia and networki ng devices (cables, hubs, switches, etc) • Configuration (via Hybrid Control Designer): − […]

-

Страница 26

Components and Architecture — Et hernet Dev ices/Considerations 16 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Note: PDE c ommunications, di scussed previ ously, do not use t he PC host connectio n sockets. PDE communications are separate from (and are transmitted concurrent with) PC host-to-controller communicat ions. The P[…]

-

Страница 27

Components and Architecture — Et hernet Dev ices/Considerations Revision 5 HC900 Hybrid Controller Installation and User Guide 17 9/03 HMI software available for use with the HC900 Controller includes, but is not necessarily limited to the packages whos e descriptions foll ow. • available from Honeywell − PlantScape SCADA or Vista Software, whi[…]

-

Страница 28

Components and Architecture — Et hernet Dev ices/Considerations 18 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 E-Mail Communications The HC900 Controller includes e-mail software that enables communication of Alarms and Even ts to up to three Internet addresses. Implementing this feature consists of: • Using the Hybrid Con[…]

-

Страница 29

Components and Architecture — Serial Ports (RS23 2 and RS485) Revision 5 HC900 Hybrid Controller Installation and User Guide 19 9/03 Serial Ports (RS232 and RS485) Overvie w • Ports configurab le as ELN, Modbus RTU or Modbus TCP protocol. • Controller ca n act as Modbus master or slave thr ough either port . • Controller can be ma ster to sla[…]

-

Страница 30

Components and Architecture — Serial Ports (RS23 2 and RS485) 20 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 RS-232 RS-232 ELN P r otoco l ELN Protocol 2000 Ft 2000 Ft ELN and ELN ELN proto col ELN protocol RS 485 RS 485 1 RS-232 RS-232 RS 485 RS 485 ELN protocol ELN protocol Modbus Modbus Slave Slave Protocol Protocol 2000 […]

-

Страница 31

Components and Architecture — Serial Ports (RS23 2 and RS485) Revision 5 HC900 Hybrid Controller Installation and User Guide 21 9/03 A L M I % Honeywell RS-232 RS-232 RS 485 RS 485 Modb us Modbus Ma ste r Master Protocol Protocol Modb us Modbus Sl ave Slave Protoc ol Protocol 2000 Ft 2000 Ft Modbus Sl ave and Modbus Maste r 3rd Party HM I Modbus M […]

-

Страница 32

Components and Architecture — Net working Basics Reference 22 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 See also Refer to Com munications In stallation on pa ge 85 for detail s on communicat ions. Networking Basics Reference The followin g information pr ovides a basic refe rence for identifyin g and applying networking co[…]

-

Страница 33

Components and Architecture — Net working Basics Reference Revision 5 HC900 Hybrid Controller Installation and User Guide 23 9/03 operates in La yer 3, IP opera tes at Layer 2, and Ethe rnet itself includes protocols that o perate at Layers 1 and 2.[…]

-

Страница 34

Components and Architecture — Net working Basics Reference 24 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Characteristics of Net w orking Dev ices Table 2 summarizes the characteristics of a set of «gen eric» netw orking devices. The information i n this table is intende d to provide a basic overview of each t ype […]

-

Страница 35

Components and Architecture — Net working Basics Reference Revision 5 HC900 Hybrid Controller Installation and User Guide 25 9/03 Table 3 — Open System Interc onnection Model Layer Number .. Name Function Components reside in: Protocols (examples) Network components affected (examples) 7. Application Identifies communication s partners, quality of […]

-

Страница 36

Components and Architecture — Net working Basics Reference 26 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 4 — Networking Device Types Network Device Description Notes Hub A Hub is so called because a diagram of its connections re sembles a hub of a s poked wheel. Characteristics: Echoes a message on any port to all oth[…]

-

Страница 37

Components and Architecture — Net working Basics Reference Revision 5 HC900 Hybrid Controller Installation and User Guide 27 9/03 Table 5- Glossary of Networking Terms Name/Acronym Name/Definiti on Comments 10Base-Tx Specification for 10mbps carried over twisted-pair cable. In the name 10 Base-T, the “10” refers to 1 0 Mbps transmission speed, […]

-

Страница 38

Components and Architecture — Net working Basics Reference 28 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Name/Acronym Name/Definiti on Comments Collision Simultaneous transm ission of two no des on the same channel. Collisions can be reduced (and network capacity increased) by use of Switc hes, wh ich partition and isolate […]

-

Страница 39

Components and Architecture — Net working Basics Reference Revision 5 HC900 Hybrid Controller Installation and User Guide 29 9/03 Name/Acronym Name/Definiti on Comments Domain Nam e A text nam e, appended to the Host name. Identifies a node as a m ember of a domain. DS1, DS3 Dedicated leased telephone lines DS1 (T-1) carries 1.544 Mbp s, DS3 (T-3) […]

-

Страница 40

Components and Architecture — Net working Basics Reference 30 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Name/Acronym Name/Definiti on Comments IP Address Internet Protocol A ddress Guaranteed u nique address, assi gned by the Internet Corp oration for Assign ed Names and Numbers (ICANN ). IP address includes four “octets[…]

-

Страница 41

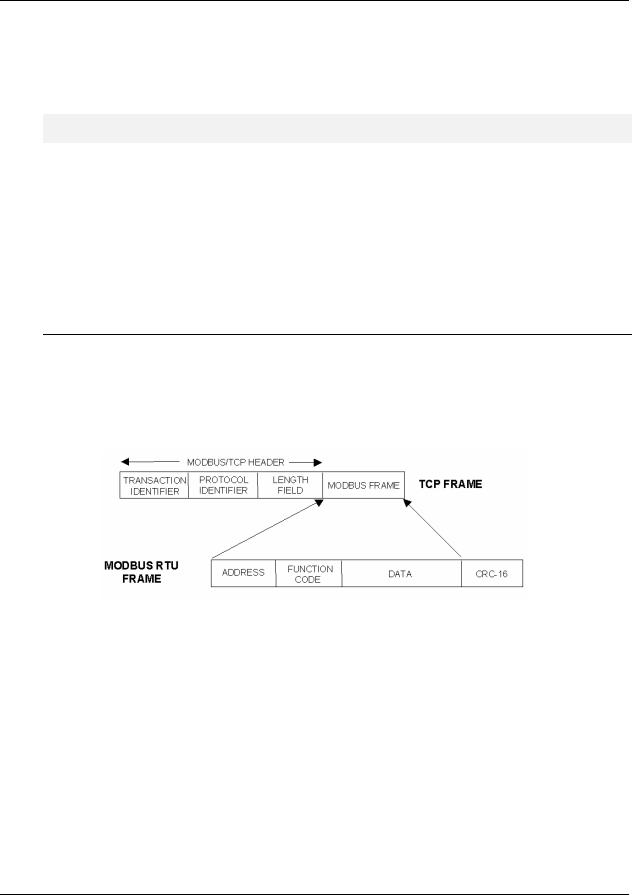

Components and Architecture — Net working Basics Reference Revision 5 HC900 Hybrid Controller Installation and User Guide 31 9/03 Name/Acronym Name/Definiti on Comments Modbus TCP/ IP Variant of M odbus protocol Modbus TCP/I P is a derivative o f related Modbus protocol used with RS-232 or RS-4 85 data acquisition and superv isory structures. Basic[…]

-

Страница 42

Components and Architecture — Net working Basics Reference 32 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Name/Acronym Name/Definiti on Comments Node Any intelligent device that includes a hard ware address that can be recognized by other networ k devices. The “node” termino logy is sometimes limite d to computing device[…]

-

Страница 43

Components and Architecture — Net working Basics Reference Revision 5 HC900 Hybrid Controller Installation and User Guide 33 9/03 Name/Acronym Name/Definiti on Comments RJ-45 Style of co nnector at end of Ethernet twisted-pair cable Router A device that is capa ble of filtering messages based on IP addresses. Routers diffe r from Bridges a nd Switc[…]

-

Страница 44

Components and Architecture — Net working Basics Reference 34 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Name/Acronym Name/Definiti on Comments Telnet Application that provides a terminal interface between hosts usin g TCP/IP. Telnet defines a protocol that al lows a remote terminal session to be established with an Interne[…]

-

Страница 45

Pre-Installation Planning — Networkin g Basics Reference Revision 5 HC900 Hybrid Controller Installation and User Guide 35 9/03[…]

-

Страница 46

Pre-Installation Planning — Overview 36 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Pre-Installation Planning Overview Methodical pre-planning of an installatio n will precl ude false starts and errors that can cause co stly hardware re-co nfiguration and/or poor system performance. Some consi derations in p re-installation […]

-

Страница 47

Pre-Installation Planning — Power Supply Selection Revision 5 HC900 Hybrid Controller Installation and User Guide 37 9/03 Power Supply Selection To determine which power supply to use, calculate power requirements below. ATTENTION Using inadequate power supply will cause the controller to cycle power on and off. Enter quantity of each modul e type […]

-

Страница 48

Pre-Installation Planning — Environment 38 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Environment Environmental Operating Limits The environmental conditions requ ired for operating the HC900 Hybrid Controller are listed Table 6. Table 6 — Operating Limits and Installation Guidelines Condition Specifications Ambient Tempera[…]

-

Страница 49

Pre-Installation Planning — Or ientation of Rac k Mounting Revision 5 HC900 Hybrid Controller Installation and User Guide 39 9/03 The HC900 C ontroller must be mounted in s uitable equipment enclosures. T hat is, all com ponents such as the Controller rack, IO Expander R acks, and the Operator Interface m a nufactured by Honey well must be mounted […]

-

Страница 50

Pre-Installation Planning — Heat Rise De-r ating 40 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Figure 18 — AC Input Module de-Rating Figure 19 — Po w er Supply De-rating[…]

-

Страница 51

Pre-Installation Planning — Equi pm ent Placement Considerations Revision 5 HC900 Hybrid Controller Installation and User Guide 41 9/03 Equipment Placement Considerations Factors that determine where equipment should be located within the site include at least the following: • Environmental conditions (see above). • Wiring/cabling characteristi[…]

-

Страница 52

Pre-Installation Planning — Electrical Co nsiderations 42 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Controller rack connected via two Ethernet Hubs to I/O expansion racks (C50 CPU only) Length of Ethernet cable, each segment: 328 feet (100 meters). Note: The use of Ethernet ca bles in excess of 100 m eters and/or devices o[…]

-

Страница 53

Pre-Installation Planning — Electrical Co nsiderations Revision 5 HC900 Hybrid Controller Installation and User Guide 43 9/03 Figure 20 — Cabinet Wiring, Single Chassis Figure 21 — Cabinet Wiring, Multiple Chassis[…]

-

Страница 54

Pre-Installation Planning — Electrical Co nsiderations 44 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 CE Conformity Electrical noise produces undesirable effect s in measurements and control circuits. Digital equipment is especially sensitive to the e ffects of electrical noise. You should use the following methods to red uc[…]

-

Страница 55

Pre-Installation Planning — Electrical Co nsiderations Revision 5 HC900 Hybrid Controller Installation and User Guide 45 9/03 System Monitor Function Blocks The HC900 C ontroller include s function blocks t hat enable the user t o monitor the status of system functions. When constructi ng a control confi guration, add t he following f unction block[…]

-

Страница 56

Pre-Installation Planning — Electrical Co nsiderations 46 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Figure 22 — Master Control Relay Wiring Example[…]

-

Страница 57

Pre-Installation Planning — Electrical Co nsiderations Revision 5 HC900 Hybrid Controller Installation and User Guide 47 9/03 Rack Dimensions Rack dimensions, including overall dimensions and patterns for drilling holes for mounting, are give n in Figure 23. Vertical spacing of racks, which is required for rack ventilation and for routing wires, is[…]

-

Страница 58

Pre-Installation Planning — Electrical Co nsiderations 48 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Site Plan Documentation Documenti ng the plan for inst alling a process co ntrol structure yiel ds significant benefi ts: • The task of instal lation plann ing itself is facilitated. • Properly organized docum entation g[…]

-

Страница 59

Installation Guide — Overview Revision 5 HC900 Hybrid Controller Installation and User Guide 49 9/03 Installation Guide Overview This section c ontains procedures for installing one or more HC900 C ontrollers. It is recommended t hat the Site Plan Documentation, completed as a part of Pre -Installati on Planning, is used as a primary data source an[…]

-

Страница 60

Installation Guide — Overview 50 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 10 — Site and Equipment Preparation Step Procedure Refer ence 1 Referring to Site Plannin g Documentation, ensure that sufficient numbers of the following items are on hand: • Racks (4-, 8- and 12-slot) • Power Supplies (1 per rack) • Co[…]

-

Страница 61

Installation Guide — Overview Revision 5 HC900 Hybrid Controller Installation and User Guide 51 9/03 Step Procedure Refer ence 4 Install (or verify co rrect installa tion of): • External disconnect s witches • Fuses at the power source associated with input sensor or output devices for I/O modules. I/O Module Installation section in this manual[…]

-

Страница 62

Installation Guide — Overview 52 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 11 — Install HC900 Controller Components Step Procedure Comments/Referen ces Mount the Controller Rack in the enclosure as follows. • Using the diagram below as a guide, mark the locations for rack mounting in the enclosure for the top holes[…]

-

Страница 63

Installation Guide — Overview Revision 5 HC900 Hybrid Controller Installation and User Guide 53 9/03 Step Procedure Comments/Referen ces 2 Aluminum grounding bars for I/O module wiri ng are optional. T hey can be mounted at t op, at bottom, or at top and botto m of the rack, as indicated at right. If grounding bars ar e included, attach them with t[…]

-

Страница 64

Installation Guide — Overview 54 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Step Procedure Comments/Referen ces Hazardous Voltage • Ensure that wiring to the Power Supply is di sconnected fro m the site AC source before installing wiring. • Do not remove Yellow/Green wire from groundi ng stud on the power supply. Failur[…]

-

Страница 65

Installation Guide — Overview Revision 5 HC900 Hybrid Controller Installation and User Guide 55 9/03 Step Procedure Comments/Referen ces 6 Ensure that jumpers are installed in J9 o n the Controlle r Module as shown at right. 7 Ensure that AC power to the rack is disconnected. Carefully place the Controlle r Module in the local rack, immediately to […]

-

Страница 66

Installation Guide — Overview 56 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Step Procedure Comments/Referen ces 8 For each I/O e xpansion rack (C50 CP U only), set the Scanner Module jumpers to the appropriate Rack Address as shown at right. Repeat steps 1t hrough 5 for each I/O expansion rack (C50 CPU only). Then, for each[…]

-

Страница 67

Revision 5 HC900 Hybrid Controller Installation and User Guide 57 9/03 I/O Module Installation and Wiring Overview This section c ontains descriptions of and procedu res for install ing I/O Modules in c ontroller racks a nd in I/O expansi on racks(C50 C PU only). Module Placement in Racks Each input or output module i s placed in an I/O slot in a r[…]

-

Страница 68

I/O Module Installation and Wiring — Module Placement in Racks 58 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Terminal Block Styles The terminal block is available in the barrier style, shown at left in Figure 26, and the Euro style, shown at right. Both styles of t erminal blocks ha ve an embossed n umbering «key»[…]

-

Страница 69

I/O Module Installation and Wiring — Remote Termination Panel (RT P) Revision 5 HC900 Hybrid Controller Installation and User Guide 59 9/03 Remote Termination Panel (RTP) The optional Remote Termination Panel (RTP) provides an easy way to connect the HC900 controller to the field wiring. The RTP integrates som e of the typi cal externally connected[…]

-

Страница 70

I/O Module Installation and Wiring — Terminal Block-to-Field (Signal) Wiring 60 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Signal Grounding The shield for each input sh ould be grounded at the grounding bar (optional) at the top or botto m of each rack as indicated in Figure 27. For low -frequency noise rejection, I/O wi ri[…]

-

Страница 71

I/O Module Installation and Wiring — Terminal Block-to-Field (Signal) Wiring Revision 5 HC900 Hybrid Controller Installation and User Guide 61 9/03 Terminal Block Jumper Combs Two styles of terminal block jumper combs are availabl e for use with the barrier-style terminal blo cks: ten- position and two position. The ten-posi tion jumpers are used w[…]

-

Страница 72

I/O Module Installation and Wiring — Remo val and Insertion Under Power (RIUP) 62 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Removal and Insertion Under Power (RIUP) Read and un derstand all of th e following inform ation regardin g RIUP before at tempting to rem ove and/or replace any I/O module, pa rticul arly in a system[…]

-

Страница 73

I/O Module Installation and Wiring — I/O Installation Procedures Revision 5 HC900 Hybrid Controller Installation and User Guide 63 9/03 I/O Installation Procedures Table 14 — Connect Input/Output Wiring Step Procedure Co mments Refer ence 1 Using Rack #, Slot #, Channel # data from a Hybrid C ontrol Designe r report and/or from document ation aids […]

-

Страница 74

I/O Module Installation and Wiring — I/O Installation Procedures 64 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Step Procedure Co mments Refer ence 4 For each configur ed and labeled I/O M odule, break off the «key-tabs» in the pattern that identifies each module ty pe. (For a d iagr am of each key-tab pattern, use[…]

-

Страница 75

I/O Module Installation and Wiring — I/O Installation Procedures Revision 5 HC900 Hybrid Controller Installation and User Guide 65 9/03 Step Procedure Co mments Refer ence NOTE: In the diagram below, t he wh ite cut-outs represent the cu t-outs on the modules that accommodate tabs on the Terminal Block. Th at is, all key-tabs that line up with the […]

-

Страница 76

I/O Module Installation and Wiring — I/O Installation Procedures 66 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Step Procedure Co mments Refer ence 5 Using the following reference item s: • Hybrid Control Designer data • Documentation Aids from Appendix A • Labels in I/O Terminal Block assemblies • Wiring diagram s g[…]

-

Страница 77

I/O Module Installation and Wiring — I/O Installation Procedures Revision 5 HC900 Hybrid Controller Installation and User Guide 67 9/03 Step Procedure Co mments Refer ence 7 Connect wire shield to groundin g bars on top and/or bott om of the Rack. (Refer to Signal Grounding, at the beginning of this section, for suggestions and recommendati ons.) 8[…]

-

Страница 78

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams 68 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 I/O Terminal Block Wiring Diagrams Universal Analog Input Module Wiring The Universal Analog Input Module has eight inputs, whi ch can include any comb ination of the following input types: RTD, TC, Ohms, Mi[…]

-

Страница 79

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams Revision 5 HC900 Hybrid Controller Installation and User Guide 69 9/03 Figure 31 — Universal Anal og Input Wiring Diagram Figure 32 — Examples of RTD Input Wiring[…]

-

Страница 80

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams 70 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Figure 33 — Analog Input Wiring — Eight TCs Figure 34 — Analog Input Wiring — Eight Resistanc e Inputs[…]

-

Страница 81

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams Revision 5 HC900 Hybrid Controller Installation and User Guide 71 9/03 Figure 35 — Analog Input Wiring — Eight RTDs I RTD 1 & 2 I RTD 1 & 2 I 3 RTD & 4 I 3 RTD & 4 I 5 RTD & 6 I 5 RTD & 6 I 7 RTD & 8 I 7 RTD & 8 Slidewires IN 2 + IN 2 — IN 1- IN […]

-

Страница 82

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams 72 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Analog Output Module Wiring An example o f Analog Output Module wiring is s hown in Figure 37. Specificati ons for this modul e and for other modul es are given in t he Specifications section of this manual.[…]

-

Страница 83

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams Revision 5 HC900 Hybrid Controller Installation and User Guide 73 9/03 DC Input Module Wiring The DC Input Module has sixteen inputs, in two grou ps of eight inputs per grou p. The groups are isolated from each other; inputs are non-isolate d within each group. An example of Di[…]

-

Страница 84

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams 74 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Figure 39 — DC Input Module Jumper[…]

-

Страница 85

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams Revision 5 HC900 Hybrid Controller Installation and User Guide 75 9/03 AC Input Module Wiring The AC Inp ut Module has six teen inputs. An e xample of AC In put Module wi ring is shown i n Figure 40. Specifications for this module and for other modules are given in the Specific[…]

-

Страница 86

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams 76 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Figure 41 — AC Input Module Jumper[…]

-

Страница 87

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams Revision 5 HC900 Hybrid Controller Installation and User Guide 77 9/03 Contact Input Module Wiri ng The Contact In put Module ha s sixteen inputs in one group. An e xample of Contact I nput wiring i s shown in Figure 42 Specifications fo r the Contact Input M odule and other m […]

-

Страница 88

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams 78 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 DC Output Module Wiring The DC Output Module prov ides 16 current-sinking ou tputs in two groups of eight poin ts per group. The two groups are isolated from each other; outputs are non-isolated with in each[…]

-

Страница 89

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams Revision 5 HC900 Hybrid Controller Installation and User Guide 79 9/03 Figure 43 — DC Output Module Wiring Diagram Figure 44 — DC Output Jumpers[…]

-

Страница 90

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams 80 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 AC Output Module Wiring The AC Out put Module provi des eight output circuits. Each out put is isolat ed from the other outputs. An example of AC output wirin g is shown in Fi gure 45. Specifi cations for th[…]

-

Страница 91

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams Revision 5 HC900 Hybrid Controller Installation and User Guide 81 9/03 Figure 45 — AC Output Module Wiring Diagram Figure 46 — AC Output Module Jumper[…]

-

Страница 92

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams 82 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Relay Output Module Wiring The Relay Out put Module provi des eight indi vidually isolat ed, electromechanical rel ay outputs. Four of the outputs are Form-C, and the o ther four are Form-A. A schematic show[…]

-

Страница 93

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams Revision 5 HC900 Hybrid Controller Installation and User Guide 83 9/03 Hazardous voltage s exist at terminal blocks. • Using switches at field devices, discon nect the fi eld wiring from power sources before servic ing. Failure to comply w ith these instructions could re sult[…]

-

Страница 94

I/O Module Installation and Wiring — I/O Terminal Block Wiring Diagrams 84 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Figure 49 — Relay Output Module Jum pers[…]

-

Страница 95

Revision 5 HC900 Hybrid Controller Installation and User Guide 85 9/03 Communications Installation Overview This section c ontains descripti ons of and pro cedures and recom mendations for i nstalling comm unications systems and c omponents. . Table 15 — Connect Communications Wiring and Cabling Step Procedure Co mments Refer ence 1 Determine requi[…]

-

Страница 96

Communications Insta llation — Overview 86 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 16 — Links to Controller Communication Ports Controller Port /Connector Type Link Type: Controller to Cable Type To Device/Port Reference Da ta RS-232 (9-pin “D” connector) Desktop or Laptop PC RS-232 Null Modem cable, up to 50?[…]

-

Страница 97

Communications Insta llation — Overview Revision 5 HC900 Hybrid Controller Installation and User Guide 87 9/03 Controller Port /Connector Type Link Type: Controller to Cable Type To Device/Port Reference Da ta 10Base-T RJ45 I/O expansion link(C50 CPU only) Shielded CAT5E crossover cable, up to 100 meters between Controller and hub, and hub-to-hub. […]

-

Страница 98

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software 88 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Connecting the HC900 Controller to a PC with the Hybrid Control Designer Software To establish c ommunicati ons between the HC 900 controlle r and the Hybrid C ontro[…]

-

Страница 99

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software Revision 5 HC900 Hybrid Controller Installation and User Guide 89 9/03 A. Direct Serial RS-232 Connection RS-232 (9.6 — 38.4 KB) Null Modem cab le RS-232 Configu ratio n port Com1 — Co m 8 PC Step Procedure 1 Prepare a null modem cable.[…]

-

Страница 100

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software 90 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 RS-232 Direct Link to PC Configuration Tool The Controller can be connected d irectly to the PC, in which case a Null Modem Cable is required. The Null Modem cable i[…]

-

Страница 101

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software Revision 5 HC900 Hybrid Controller Installation and User Guide 91 9/03 RS-232 Remote Connection to PC Configura tion Tool The Controll er can also be connect ed remotely by a set of modem s, which are availa ble from third- party suppli[…]

-

Страница 102

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software 92 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 B. Modem Connection Modem 9.6 — 38.4 KB Internal Modem assigned to a COM port PC RS-232 Configuration port Step Procedure 1 Connect a modem to the HC900 controller ?[…]

-

Страница 103

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software Revision 5 HC900 Hybrid Controller Installation and User Guide 93 9/03 Modem requirements Most commercially available modem s can be used w ith the HC900 Controller. The modem must have the following capabilities: • RS-232 interface ?[…]

-

Страница 104

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software 94 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Modem configuration Before connect ing a modem to the controller ’s RS-232 port (marked “CONFIGUR ATION”), the m odem must be configured with the follo wing se[…]

-

Страница 105

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software Revision 5 HC900 Hybrid Controller Installation and User Guide 95 9/03 Modem configuration examples Below are procedures for setting up the following commercially available modems: • 3Com US Robotics 56K Data/Fax External Modem • Zo[…]

-

Страница 106

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software 96 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Step Action 8 Key in the following comman d string: AT Y0 Then, press the ENTER key. The modem should respond with OK. 9 Key in the following comman d string: AT &am[…]

-

Страница 107

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software Revision 5 HC900 Hybrid Controller Installation and User Guide 97 9/03 Zoom 56K Dualmode External Modem Step Action 1 Connect the modem to a PC. If y our PC’s RS -232 port has a 25-pin con nector, use a DB-25 male to DB-25 female RS-2[…]

-

Страница 108

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software 98 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Best Data 56SX Data Fax Extern al Modem Step Action 1 Con nect the modem to a PC. If your PC’s RS-232 port has a 2- pin connector, use a DB-9 male to DB-25 female […]

-

Страница 109

Communications Installation — Conn ecting the HC900 Controller to a PC with the H ybrid Control Designer Software Revision 5 HC900 Hybrid Controller Installation and User Guide 99 9/03 SixNet VT-MODEM Industrial External M odem Step Action 1 Con nect the modem to a PC. If your PC’s RS-232 port has a 25 pin connector, use a DB-9 male to DB-25 fema[…]

-

Страница 110

Communications Installation — RS-485 L ink to Operator Interface 100 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 RS-485 Link to Operator Interface The RS-485 port is located belo w the hinged plastic cover on the top part of the Controller Module. Typically, the cable that interconnects this port to the Operator Interface mu[…]

-

Страница 111

Communications Installation — RS-485 L ink to Operator Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 101 9/03 C. Direct Ethernet Conne ction to one HC900 controller Ethern et 10 Base- T Crossover cable Defaults : IP Address: 192.168.1.254 Subnet M ask: 255.255. 255.0 Default G ateway: 0.0. 0.0 Host 10Ba se-T Ethernet por […]

-

Страница 112

Communications Installation — RS-485 L ink to Operator Interface 102 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Step Procedure 8 Select the Set Controller ’s Network Parameters bu tton. Using the wizard (bottom radio button), select the PC port to be used, t hen set the controller’s ne w network parameters including IP […]

-

Страница 113

Communications Installation — RS-485 L ink to Operator Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 103 9/03 D. Network Access to one or more controllers Ethern et 10Base -T LAN Hub/Swit ch 165.125. 163.25 16 5.125. 163.26 PC Step Procedure 1 Make sure the PC has an Ethernet NIC (Network In terface Card) install ed and e[…]

-

Страница 114

Communications Installation — RS-485 L ink to Operator Interface 104 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Setting Up the Controller Net w ork Parameters See the HC900 H ybrid Control De signer Users Guide, Do c. # 51-52-25-110 or respectiv e HC Designer Help Files for setting u p following netwo rk parameters: • IP […]

-

Страница 115

Communications Installation — Conn ecting the HC900 Controller to Modbus device(s) Revision 5 HC900 Hybrid Controller Installation and User Guide 105 9/03 Connecting the HC900 Controller to Modbus device(s) RS-485 Modbus connections Using the master and slave (s) RS- 485 ports of the controlle r and other device(s), connect as sho wn. Master 120 oh[…]

-

Страница 116

Operating Characteristics — Connecting t he HC900 Co ntroller to Modbus device(s) 106 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03[…]

-

Страница 117

Operating Characteristics — Introduction Revision 5 HC900 Hybrid Controller Installation and User Guide 107 9/03 Operating Characteristics Introduction This section pr ovides insights into system fu nctioning that are useful in configuration, in installation /commissi oning tasks, and al so in normal and abnor mal operation. For related information[…]

-

Страница 118

Operating Characteristics — Power Down / Power Up 108 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Figure 52 — Warm Start Operation Cold Start A Cold Start clears the data in battery backed RAM, turns all out puts off, transf ers the configuration file from flash memory to RAM and reinitializes all dynamic data. The Cold Star[…]

-

Страница 119

Operating Characteristics — Power Down / Power Up Revision 5 HC900 Hybrid Controller Installation and User Guide 109 9/03 Figure 53 — Cold Start Operation[…]

-

Страница 120

Operating Characteristics — Controller Mode s 110 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Controller Modes The HC900 C ontroller include s three operating m odes. The purpose of ea ch mode is desc ribed immediately below, and salient characteristics of each are described in Table 19. The funct ions of the Mode Switch are[…]

-

Страница 121

Operating Characteristics — Controller Mode s Revision 5 HC900 Hybrid Controller Installation and User Guide 111 9/03 Table 19 — Controller Operating Modes Mode Name Functions in selected mode RUN I/O scanning (Controller and Expander Racks) Function block execution; outputs are set according to function bl ock algorithms. Monitoring of Diagnostics[…]

-

Страница 122

Operating Characteristics — Controller Mode s 112 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Controller Mode Transitions Mode chan ges are controlled primarily by positioning of t he MODE switch on the contro ller module, an d secondarily by selection of mode nam es on operator interface displays. That is, the M ode switch […]

-

Страница 123

Operating Characteristics — Controller Mode s Revision 5 HC900 Hybrid Controller Installation and User Guide 113 9/03 Table 21 — Controller Behavior in Mode Transi tion Initial Mode Ne w Mode Controller Behavior PROGRAM RUN Validate co nfiguration database. Reset all I/O scanners. Upon startup, initiate Cold Start sequence. Diagnostic: Identify and[…]

-

Страница 124

Operating Characteristics — Software Download/U pload Functions 114 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Software Download/Upload Functions The following is a general descri ption of software file transfers between th e controll er and comput er devices external to the controller. Performing download proced ures incor[…]

-

Страница 125

Operating Characteristics — Software Download/U pload Functions Revision 5 HC900 Hybrid Controller Installation and User Guide 115 9/03 Configuration Download Configuration files include the items indicated in Tab le 22. Downloading of some items is mode dependent. T hat is, download ing of some file types is not p ermitted in the R un mode or in t[…]

-

Страница 126

Operating Characteristics — Software Download/U pload Functions 116 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03[…]

-

Страница 127

Revision 5 HC900 Hybrid Controller Installation and User Guide 117 9/03 Diagnostics and Troubleshooting Overview The HC900 system incorpora tes a comp rehensive set of diagnostic tools that test ha rdware and software operation. Diagnostic soft ware elements are contai ned i n each system component. The diagnostic elements that are executed at any […]

-

Страница 128

Diagnostics and Troublesh ooting — External Indications of Diagnostic Information 118 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Figure 55 — LED Indicators[…]

-

Страница 129

Diagnostics and Troublesh ooting — External Indications of Diagnostic Information Revision 5 HC900 Hybrid Controller Installation and User Guide 119 9/03 Table 23 — LED Indications on Main CPU LED LED State/Color Indicates Condition: Controller Status Off Solid Red Blinking Red Solid Green Blinking Green Solid Yellow No power. Failed (Diagnostic Co[…]

-

Страница 130

Diagnostics and Troublesh ooting — External Indications of Diagnostic Information 120 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 24 — LED Indications on Scanner Module LED LED State/Color Indicates Condition: Scanner Status Off Solid Red Blinking Red Solid Green Blinking Green No power. Failed (Diagnostic Code; refer […]

-

Страница 131

Diagnostics and Troublesh ooting — User Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 121 9/03 Table 26 — LED Indications on Ethernet Hu b LED LED State/Color Indicates Condition: Green (On/Off) Green (On/Off) On while a message is being sent from the Main CPU; otherwise Off. On while the Main CPU is receiving a message. […]

-

Страница 132

Diagnostics and Troublesh ooting — User Interface 122 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 27 — Controller Modul e Diagnostics OI Screen Item OI Screen Item Value Number of LED Strobes Possible Cause Control File Action User Action INVALID CONFIG. 2 A configuration t hat exceeds the loop capacity of the controll[…]

-

Страница 133

Diagnostics and Troublesh ooting — User Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 123 9/03 Table 27 — Controller Modul e Diagnostics OI Screen Item OI Screen Item Value Number of LED Strobes Possible Cause Control File Action User Action DATA ABORT 3 CPU failed when attempting to access data. See PREFETCH ABORT. See P[…]

-

Страница 134

Diagnostics and Troublesh ooting — User Interface 124 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 27 — Controller Modul e Diagnostics OI Screen Item OI Screen Item Value Number of LED Strobes Possible Cause Control File Action User Action COMPORT GOOD N/A N/A N/A N/A FAILED N/A One of the Comm ports is reporting a phys[…]

-

Страница 135

Diagnostics and Troublesh ooting — User Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 125 9/03 Table 27 — Controller Modul e Diagnostics OI Screen Item OI Screen Item Value Number of LED Strobes Possible Cause Control File Action User Action IO RACK COMM FAIL 6 The Main CPU is unable to successfully communicate to an expa[…]

-

Страница 136

Diagnostics and Troublesh ooting — User Interface 126 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 27 — Controller Modul e Diagnostics OI Screen Item OI Screen Item Value Number of LED Strobes Possible Cause Control File Action User Action MODULE 1 through MODULE 16 GOOD N/A N/A N/A N/A HI CJ TEMPERAT URE 6 Possible cau[…]

-

Страница 137

Diagnostics and Troublesh ooting — User Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 127 9/03 Table 27 — Controller Modul e Diagnostics OI Screen Item OI Screen Item Value Number of LED Strobes Possible Cause Control File Action User Action MODULE 1 through MODULE 16 MODULE NO COMM 6 Main CPU is unable to communicate to […]

-

Страница 138

Diagnostics and Troublesh ooting — User Interface 128 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 27 — Controller Modul e Diagnostics OI Screen Item OI Screen Item Value Number of LED Strobes Possible Cause Control File Action User Action XIO PORT GOOD N/A N/A N/A N/A DLFAIL 6 The communications to a particular rack is[…]

-

Страница 139

Diagnostics and Troublesh ooting — User Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 129 9/03 Table 27 — Controller Modul e Diagnostics OI Screen Item OI Screen Item Value Number of LED Strobes Possible Cause Control File Action User Action XIO PORT HWFAIL 6 The power-up test of the expansion rack(C50 CPU only) Ethernet […]

-

Страница 140

Diagnostics and Troublesh ooting — User Interface 130 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 27 — Controller Modul e Diagnostics OI Screen Item OI Screen Item Value Number of LED Strobes Possible Cause Control File Action User Action RS-232 GOOD N/A N/A N/A N/A DATA LINK FAILURE 8 A large numbe r of messages are r[…]

-

Страница 141

Diagnostics and Troublesh ooting — User Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 131 9/03 Table 27 — Controller Modul e Diagnostics OI Screen Item OI Screen Item Value Number of LED Strobes Possible Cause Control File Action User Action RS-232 HW FAILURE 8 The DUA RT failed its power-up tests. 1. Rack 1 monitor bl oc[…]

-

Страница 142

Diagnostics and Troublesh ooting — User Interface 132 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 27 — Controller Modul e Diagnostics OI Screen Item OI Screen Item Value Number of LED Strobes Possible Cause Control File Action User Action RACK 1 VIRTUAL CONNECT 1 – 5 GOOD N/A N/A N/A N/A APPLICATION ERROR 10 At least[…]

-

Страница 143

Diagnostics and Troublesh ooting — User Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 133 9/03 I/O Module Diagnostics To indicate the type of diagnostic failure, the module’s status LED is flashed red with a number of quick strobes followed by a long off time. The table below outlines the potential module diagnostics. T[…]

-

Страница 144

Diagnostics and Troublesh ooting — User Interface 134 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Bad I/O Channel Diagnostics Below is a li st of conditions t hat can cause a bad c hannel diagnostic. T he associated funct ion block’s I/ O status will indicate the nature of the diagnostic described in the failure column. Ta[…]

-

Страница 145

Diagnostics and Troublesh ooting — User Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 135 9/03 Scanner Diagnostic LED Indication The scanner uses its LED to comm unicate diagnostic informa tion. These diagnostics are a subset of the main CPU’s and are listed below. Table 30 — Scanner Diagnostics Table 30 — Scanner Diagn[…]

-

Страница 146

Diagnostics and Troublesh ooting — User Interface 136 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 30 — Scanner Diagnostics Diagnostic Condition Number of Strobes Possible Cause Scanner Action User Action Communication failure to main- CPU 2 The scanner is not receiving any messages from the main CPU. Does no scanning o[…]

-

Страница 147

Diagnostics and Troublesh ooting — User Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 137 9/03 Table 30 — Scanner Diagnostics Diagnostic Condition Number of Strobes Possible Cause Scanner Action User Action Watchdog Reset 3 Watchdog reset resulting from software failure Scanner restarts and requests configuration from the[…]

-

Страница 148

Diagnostics and Troublesh ooting — User Interface 138 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Table 30 — Scanner Diagnostics Diagnostic Condition Number of Strobes Possible Cause Scanner Action User Action High CJ temperature 6 Possible reasons for this diagnostic are: 1. One of the t wo CJs on the module is indicating a[…]

-

Страница 149

Diagnostics and Troublesh ooting — User Interface Revision 5 HC900 Hybrid Controller Installation and User Guide 139 9/03[…]

-

Страница 150

Revision 5 HC900 Hybrid Controller Installation and User Guide 140 9/03 Analog Calibration Overview All calibration data for Analog Input Modules and An alog Output Modules is stored in non-volatile memory in the I/O m odules. Calibration data is st ored for each channel of each AI or AO module. Calibration data for each ch annel can be either: •[…]

-

Страница 151

Analog Calibration — Overvie w Revision 5 HC900 Hybrid Controller Installation and User Guide 141 9/03 Analog Input Calibration Analog input modules can accom modate five input types: • RTD • Thermocouple • Ohms • Volt and milliVolt • 4-20 m A Calibration values for each channel are stored in the mo dule as num eric values paired with A/D[…]

-

Страница 152

Analog Calibration — Overvie w 142 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 IN 2 + IN 2 — I RTD 1 & 2 I RTD 3 & 4 I RTD 5 & 6 I RTD 7 & 8 IN 3+ IN 7 — IN 7 + IN 1+ IN 1 — IN 3- IN 4+ IN 5+ IN 5 — IN 6+ IN 6 — IN 8+ IN 8 — Thermocouple Inpu t* IR TD + — RTD Input mV or V Source + — mV , V Inpu t Ohms Inpu t[…]

-

Страница 153

Analog Calibration — Overvie w Revision 5 HC900 Hybrid Controller Installation and User Guide 143 9/03 Analog Output Calibration Analog outp ut modules have essentially one o utput type. A diagram of a precision ammeter connecte d to the te rmi nals of an Analog Output m odule is give n in Figure 57. The specifications of the meter must be consiste[…]

-

Страница 154

— Overview 144 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03[…]

-

Страница 155

Removal and Replacement Proced ures — Overview Revision 5 HC900 Hybrid Controller Installation and User Guide 145 9/03 Removal and Replacement Procedures Overview This section contai ns procedures for removing and replacing the active compone nts of an HC900 Hybrid Controller. It also includes r ecommendations, su ggestions, and hi nts as they ap p[…]

-

Страница 156

Removal and Replacement Proced ures — Safety Considerations — PLAN AHEAD ! 146 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 EXPLOSION HAZ ARD Class 1, Division 2 Installations • SUBSTITUTION O F COMPONENTS MA Y IMPAIR SUITABILI TY FOR CLASS I, DI VISION 2. EXPLOSION HAZ ARD Class 1, Division 2 Installations • DO NOT DISCO[…]

-

Страница 157

Removal and Replacement Proced ures — Safety Considerations — PLAN AHEAD ! Revision 5 HC900 Hybrid Controller Installation and User Guide 147 9/03 Step Action 8. Ensure po wer can be applied safely, and use th e external (user-supplied) switch to re-connect power to t he power supply . 9. Using a m eter and the test points on the face of the power […]

-

Страница 158

Removal and Replacement Proced ures — Safety Considerations — PLAN AHEAD ! 148 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Replacing the Controller Module Removing a nd replacing the C ontroller Modu le requires that that the source of AC power is removed from the rack. Removi ng power from the Controller rack has the follow[…]

-

Страница 159

Removal and Replacement Proced ures — Safety Considerations — PLAN AHEAD ! Revision 5 HC900 Hybrid Controller Installation and User Guide 149 9/03 Replacing the Scanner Module Removing a nd replacing the Scanne r Module from an I/O expansi on rack(C50 CPU only) requires that t he source of AC p ower is remove d from the rack. Removing po wer from t[…]

-

Страница 160

Removal and Replacement Proced ures — Safety Considerations — PLAN AHEAD ! 150 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Replacing an I/O Module Read and un derstand all of th e following inform ation regardin g RIUP before at tempting to rem ove and/or replace any I/O module, pa rticul arly in a system that is actively co[…]

-

Страница 161

Removal and Replacement Proced ures — Safety Considerations — PLAN AHEAD ! Revision 5 HC900 Hybrid Controller Installation and User Guide 151 9/03 Table 35 — I/O Module Replacement Step Action Removal or Insertion Under Power of an I/O m odule is an option , but if operat ing circum stances permit, disconnecting power from the rac k is the preferre[…]

-

Страница 162

Removal and Replacement Proced ures — Safety Considerations — PLAN AHEAD ! 152 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Battery Installation/Replacement Advisory Regarding Battery Installation Memory for the CPU in the C ontroller Module includes: • Volatile memory and • Non-volatile memory (Flash) Only volatile RAM r[…]

-

Страница 163

Removal and Replacement Proced ures — Safety Considerations — PLAN AHEAD ! Revision 5 HC900 Hybrid Controller Installation and User Guide 153 9/03 Battery Installation Procedures Table 36 — Installing Backup Ba ttery (CPU not initialized) Step Action 1. Improper a pplication of si te power can cause damage to eq uipment. Ensure that the contro ller[…]

-

Страница 164

Removal and Replacement Proced ures — Safety Considerations — PLAN AHEAD ! 154 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Battery Replacement Pro cedures Table 37 — Replacing a Backup Battery (CPU Powered)) Step Action 1. If the battery is removed from the Controller Module when AC power is not applied, the content of SDRAM[…]

-

Страница 165

Controller Components and modu les — Safety Considerations — PLAN AHEAD ! Revision 5 HC900 Hybrid Controller Installation and User Guide 155 9/03 Controller Components and modules RA CKS 4 I/O Slot R ack 8 I/O Slot R ack 12 I/O Slot Rack Pow er Suppli es 120/240VAC, 60W 120/240VAC, 28W CPU Assemblies Controlle r C50 CPU Config.SW & Docs Control[…]

-

Страница 166

Specifications — HC900 Hybrid Controller Design 156 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Specifications HC900 Hybrid Controller Design Controller Module Feature Description CE Conformity (Europe) This product is in conform ity with t he protection requirements of the following European Council Directives: 73/23/EEC, t[…]

-

Страница 167

Specifications — Controller Modul e Design Revision 5 HC900 Hybrid Controller Installation and User Guide 157 9/03 Controller Module Design Controller Module Feature Description Module design CPU BUS Memory Real-Time Clock Battery-Backup Input/Output Status Indicators Plug-in module: CPU, memory (RAM and Flash PROM), DUART for RS-232 and RS-485, co[…]

-

Страница 168

Specifications — Scanner Module Desi gn 158 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Scanner Module Design Controller Module Feature Description Module design CPU Memory Bus Communications Status Indicators Input/Output Plug-in module: CPU, memory (RAM and Flash PROM), communications connector, backplane connector, and su[…]

-

Страница 169

Specifications — Rack Design Revision 5 HC900 Hybrid Controller Installation and User Guide 159 9/03 Rack Design Rack Features Description Remote I/O configuration Variable capacity Multi-purpose applicability Power Supplies Input/Output Mounting; dimens ions Enables placement of I/O Mo dules near field devices. Available in three sizes (I/O module[…]

-

Страница 170

Specifications — Input Out put System: Common Features 160 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Input Output System: Common Features I/O Feature Description Slot locations Rack Complement I/O Module Pin Out put (to terminal block) Terminal Block Ty pes Hardware keying Color-coded Label Intelligent Module Light Pipes M[…]

-

Страница 171

Specifications — Analog Input, Anal og Output Modu les: Common Features Revision 5 HC900 Hybrid Controller Installation and User Guide 161 9/03 Analog Input, Analog Output Modules: Common Features Feature Description Micro Controller Motorola 68HC11 micro controller 12k One-time programmable PROM built-in diagnostics Analog Input Module Feature Des[…]

-

Страница 172

Specifications — A nalog Input Modu le 162 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Feature Description A/D resolution 15 bits Reference Junction Sens ing Via 2 RT Ds at top/bottom of module Update rate 500 ms (Analog to digital converter per module) Long Term stability 0.1% per year Channel Configuration Data Stored in n[…]

-

Страница 173

Specifications — Analog Output Modules Revision 5 HC900 Hybrid Controller Installation and User Guide 163 9/03 Analog Output Modules Feature Description Number of outputs 4 isolated outputs per module Isolation 500 Vdc Channel-Cha nnel 600 Vdc from logic Output dev ice MOSFET Load resistance 0 to 750 ohms Accuracy 0.1% of full scale at reference co[…]

-

Страница 174

Specifications — Digital Input Modules; Comm on Features 164 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Digital Input Modules; Common Features Feature Description Micro controller Atmel 8515 RISC architecture 8k Flash PROM Hardware/software keying Key matches module to terminal block connector, ensuri ng correct board repla[…]

-

Страница 175

Specifications — DC Input Module Revision 5 HC900 Hybrid Controller Installation and User Guide 165 9/03 DC Input Module Feature Description Inputs 16 (sink ing) Input Voltage Range 10 Vdc to 32 Vdc Peak Voltage 32 Vdc Isolation 2 groups of 8 inputs/group; dielectric strength bet ween groups: 42.4 Vdc (30 Vac) ON voltage lev el 9.5 Vdc minimum OFF […]

-

Страница 176

Specifications — AC Input Module 166 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 AC Input Module Feature Description Inputs 2 isol ated groups of 8 inputs each Input v oltage range 80 to 240 Vac Peak voltage 264 Vac AC frequency 47 to 63 Hz Isolation 2 groups of 8 inputs/group; dielectr ic strength bet ween groups: 500 Vdc ([…]

-

Страница 177

Specifications — DC Output Module Revision 5 HC900 Hybrid Controller Installation and User Guide 167 9/03 DC Output Module Feature Description Outputs 16 (current sink ing, low side) Isolation 2 groups of 8 outputs/group Operating Voltage 6.5 to 32 Vdc (5.0 to 6.5 V @ < 0.5 A per channel) Output type Intelligent Power Switch (IPS) Peak Voltage 3[…]

-

Страница 178

Specifications — AC Output Module 168 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 AC Output Module Feature Description Outputs 8 Isolation Per output; Jumper comb is available for connecti ng «L1» terminals Operating Voltage 85 Vac to 240 Vac Output type Tria c Peak Voltage 250 Vac AC Freque ncy 47 to 63 Hz Transie[…]

-

Страница 179

Specifications — Re lay Output Modu le Revision 5 HC900 Hybrid Controller Installation and User Guide 169 9/03 Relay Output Module Feature Description Relays per Module Form-A: 4 Form-C: 4 Output Device Electro-mecha nical relay Voltage 120/250 Vac, 30 Vdc Contact Current Rating 4 A @ 250 Vac, 30 Vdc resistive loa d Max. Leakage Current 1 mA @ 350 […]

-

Страница 180

Specifications — Environment al and Operating Conditions 170 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Environmental and Operating Conditions Parameter Reference Rated Extreme Transportation and Storage Ambient Temp. °F °C 77 ± 5 25 ± 3 32 to 131 0 to 55 32 to 140 0 to 60 –40 to 151 –40 to 66 Amb ie nt Re la t ive […]

-

Страница 181

Specifications — Environment al and Operating Conditions Revision 5 HC900 Hybrid Controller Installation and User Guide 171 9/03 HC900 Analog Input Ranges v s. UMC800 Analog Input ranges Users of UMC800 Controllers from Honeywell will find the analog range selections of the HC900 Controller differ slightl y from those avail able in the UMC 800. The[…]

-

Страница 182

Specifications — Environment al and Operating Conditions 172 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Type Range Low Range High EU (Reference): Corres ponding UMC800 Input type and range R -18 1704 C R -20 1760 C 28 R 0 3100 F R -4 3200 F 29 S -18 1704 C S 0 1600 C 30 S 0 310 0 F S 32 2912 F 31 T -184 371 C T –200 400 C[…]

-

Страница 183

Specifications — Environment al and Operating Conditions Revision 5 HC900 Hybrid Controller Installation and User Guide 173 9/03 Type Range Low Range High EU (Reference): Corres ponding UMC800 Input type and range MA 4 20 mA 4 20 100 MA 0 20 mA 0 20 99 MV 0 10 mV 0 10 88 MV 0 50 mV 0 50 92 MV 0 100 mV 0 100 95 MV -10 10 mV -10 10 89 MV -50 50 mV -5[…]

-

Страница 184

Specifications — Environment al and Operating Conditions 174 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 System Sizing Summary Alarms 240 Alternator Blocks 6 max. Analog Inputs Model C30 — 96 points ma x Model C50 — 128 points m ax. Analog Outputs Model C30 — 48 points max Model C50 — 64 points ma x. Block Config. Parameters[…]

-

Страница 185

Specifications — Environment al and Operating Conditions Revision 5 HC900 Hybrid Controller Installation and User Guide 175 9/03[…]

-

Страница 186

Revision 5 HC900 Hybrid Controller Installation and User Guide 176 9/03 Appendix A Site Planning Documentation Aids Overview This appendix con tains aids for installation planning ; these include: • An example of a set of site diagram s that suggest m ethods of showing: − Placement of e nclosures fo r controller com ponents relat ive to process[…]

-

Страница 187

Appendix A Site Planning Documentatio n Aids — Overview Revision 5 HC900 Hybrid Controller Installation and User Guide 177 9/03 • Figure 58 — Example Site Map — Equipment Placement[…]

-

Страница 188

Appendix A Site Planning Documentatio n Aids — Overview 178 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Figure 59 — Example Net work System Diagram[…]

-

Страница 189

Appendix A Site Planning Documentatio n Aids — Overview Revision 5 HC900 Hybrid Controller Installation and User Guide 179 9/03 HC900 Controller Configurator[…]

-

Страница 190

Appendix A Site Planning Documentatio n Aids — I/O Module Configurator 180 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 I/O Module Configurator Controller # ______ (1) ; Process Area _______________________________ (2) IP A ddress |_|_|_| . |_|_|_| . |_|_|_| . |_|_|_|; Subnet Mask |_|_|_| . |_|_|_| . |_|_|_| Peer Network Name[…]

-

Страница 191

Appendix A Site Planning Documentatio n Aids — I/O Module Channel Assignment Confi gurator Revision 5 HC900 Hybrid Controller Installation and User Guide 181 9/03 I/O Module Channel Assignment Configurator 1. Network # |____| (1) 2. Network Name |_|_|_|_|_|_|_|_|_ |_|_|_|_|_|_|_| (2) 2. Controller Name |_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_| Alias Name |[…]

-

Страница 192

Appendix A Site Planning Documentatio n Aids — Peer Network Configur ator 182 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Peer Network Configurator Network # ______; Network Name |_|_|_|_|_|_|_|_|_|_ |_|_|_|_|_|_| (up to 16 ASCII char’s) 1. Controller Name |_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_| Alias Name |_|_|_|_|_|_|_|_|_ […]

-

Страница 193

Revision 5 HC900 Hybrid Controller Installation and User Guide 183 9/03 Appendix B I ns t a l l a t i o n o f R e m o te Termination Panels (RTPs) Overview The Remote Termination Panel (RTP) provides an easy way to connect the HC900 controller to th e field wiring. The RTP integrates som e of the typical ex ternally con nected component s, reducing[…]

-

Страница 194

Appendix B Installation of Re mote Termination Panels (RTPs) — Analog In put 184 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Analog Input 8 Point Analog In put Step Action 1 ATTENTION: RTP is not for use w ith thermocouples. ATTENTION: RTP and cables are intended for permanent installati on within their own enclosure. Mount […]

-

Страница 195

Appendix B Installation of Re mote Termination Panels (RTPs) — Analog In put Revision 5 HC900 Hybrid Controller Installation and User Guide 185 9/03 8 Point Analog In put Step Action 3 Set DIP switch positions SW1 through S W8. Set each input’s DIP switch positions according to the input type. Refer to Figure 61 (Step 4) to determine which switch[…]

-

Страница 196

Appendix B Installation of Re mote Termination Panels (RTPs) — Analog In put 186 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 8 Point Analog In put Step Action 123456789 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 2 4 V + I N 1 + I N 5 + I R T D 5 I R T D 2 I N 2 + I R T D 3 I […]

-

Страница 197

Appendix B Installation of Re mote Termination Panels (RTPs) — Analog In put Revision 5 HC900 Hybrid Controller Installation and User Guide 187 9/03 8 Point Analog In put Step Action 1 2 3 7 8 9 4 5 6 10 11 12 13 17 18 19 14 15 16 20 21 22 23 27 28 29 24 25 26 30 31 32 33 37 38 39 34 35 36 40 + — + — + — + — + — + — mA Input 1 mA Input 2 mA Input 3[…]

-

Страница 198

Appendix B Installation of Re mote Termination Panels (RTPs) — Analog In put 188 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 8 Point Analog In put Step Action 1 2 3 7 8 9 4 5 6 10 11 12 13 17 18 19 14 15 16 20 21 22 23 27 28 29 24 25 26 30 31 32 33 37 38 39 34 35 36 40 Input 1 Input 2 Input 3 Input 4 Input 6 Input 7 Input 8 […]

-

Страница 199

Appendix B Installation of Re mote Termination Panels (RTPs) — Analog In put Revision 5 HC900 Hybrid Controller Installation and User Guide 189 9/03 8 Point Analog In put Step Action 1 2 3 7 8 9 4 5 6 10 11 12 13 17 18 19 14 15 16 20 21 22 23 27 28 29 24 25 26 30 31 32 33 37 38 39 34 35 36 40 Input 1 Input 2 Input 3 Input 4 Input 6 Input 7 Input 8 […]

-

Страница 200

Appendix B Installation of Re mote Termination Panels (RTPs) — Analog In put 190 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Analog Input RTP Internal schematic 6 7 9 10 20 19 17 16 15 14 12 11 1 2 8 18 13 3 2 22 4 6 27 8 29 12 32 13 33 16 36 17 37 20 40 5 10 11 14 15 18 19 24 21 F1 F2 F3 F4 1 F5 F6 F7 F8 25 30 31 34 35 38 3[…]

-

Страница 201

Appendix B Installati on of Remote Termination Panels (RTPs) — Rela y Output Revision 5 HC900 Hybrid Controller Installation and User Guide 191 9/03 Relay Output Relay Output Step Action 1 ATTENTION: RTP and cables are intended for permanent ins tallation within their own enclos ure. Mount RTP cable assembly to HC900 Controller (Figure 60). • Rem[…]

-

Страница 202

Appendix B Installati on of Remote Termination Panels (RTPs) — Rela y Output 192 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Relay Output Step Action 4 Connect field wiring. 123456789 10 11 12 13 14 15 16 17 18 19 20 DO-8 DO-7 DO-6 DO-5 DO-4 DO-3 DO-2 DO-1 LOAD NO LOAD NC LOAD NO LOAD NC LOAD NO LOAD NC LOAD NO LOAD NC LOAD […]

-

Страница 203

Appendix B Installati on of Remote Termination Panels (RTPs) — Rela y Output Revision 5 HC900 Hybrid Controller Installation and User Guide 193 9/03 Relay Output RTP Internal schematic HC900 Ter min al B loc k TB 1 1 2 4 5 6 7 9 10 11 12 3 8 13 14 16 17 18 19 15 20 F1 SW 1 F1 SW 1 J1 F2 SW 2 F2 SW 2 F3 SW 3 F3 SW 3 F4 SW 4 F4 SW 4 F5 SW 5 F5 SW 5 F[…]

-

Страница 204

Appendix B Installati on of Remote Termination Panels (RTPs) — Digital Input/Dig ital Output/Analog Output 194 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Digital Input/Digital Output/Analog Output The DI/DO/ AO-RTP is for u se with the followi ng modules: See page • 4-point Anal og Output 194 • 16-point Contact Digital […]

-

Страница 205

Appendix B Installati on of Remote Termination Panels (RTPs) — Digital Input/Dig ital Output/Analog Output Revision 5 HC900 Hybrid Controller Installation and User Guide 195 9/03 4 Point Analog Out put Step Action 4 Connect field wiring. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 L[…]

-

Страница 206

Appendix B Installati on of Remote Termination Panels (RTPs) — Digital Input/Dig ital Output/Analog Output 196 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 16 Point Contact Digital Input Step Action 3 Set jumper positions as shown for t he 16 point contact digita l input module. Jumper open Jumper closed SW1 is not used. Modu[…]

-

Страница 207

Appendix B Installati on of Remote Termination Panels (RTPs) — Digital Input/Dig ital Output/Analog Output Revision 5 HC900 Hybrid Controller Installation and User Guide 197 9/03 16 Point DC Digital Input Step Action 1 ATTENTION: RTP and cables are intended for pe rmanent installation within their o wn enclosure. Mount RTP cable assembly to HC900 C[…]

-

Страница 208

Appendix B Installati on of Remote Termination Panels (RTPs) — Digital Input/Dig ital Output/Analog Output 198 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 16 Point DC Digital Input Step Action 4 Connect field wiring. Note: SDC+ in the wiring figure bel ow refers to powe r that is disconnected from these screw terminals when […]

-

Страница 209

Appendix B Installati on of Remote Termination Panels (RTPs) — Digital Input/Dig ital Output/Analog Output Revision 5 HC900 Hybrid Controller Installation and User Guide 199 9/03 16 Point AC Digital Input Step Action 2 Mount RTP to DIN rail. • Latch to rail. See page 205. • Connect cable to RTP 3 Set/ verify jumper positions as shown. Jumper op[…]

-

Страница 210

Appendix B Installati on of Remote Termination Panels (RTPs) — Digital Input/Dig ital Output/Analog Output 200 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 16 Point DC Digital Output Step Action 1 ATTENTION: RTP and cables are intended for pe rmanent installation within their o wn enclosure. ATTENTION: DC Digital Output is ra[…]

-

Страница 211

Appendix B Installati on of Remote Termination Panels (RTPs) — Digital Input/Dig ital Output/Analog Output Revision 5 HC900 Hybrid Controller Installation and User Guide 201 9/03 16 Point DC Digital Output Step Action 4 Connect field wiring. Note: SDC+ in the wiring figure bel ow refers to powe r that is disconnected from these screw terminals when[…]

-

Страница 212

Appendix B Installati on of Remote Termination Panels (RTPs) — Digital Input/Dig ital Output/Analog Output 202 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 8 Point AC Digital Output Step Action 2 Mount RTP to DIN rail. • Latch to rail. See page 205. • Connect cable to RTP 3 Set/ verify jumper positions as shown. Jumper op[…]

-

Страница 213

Appendix B Installati on of Remote Termination Panels (RTPs) — Digital Input/Dig ital Output/Analog Output Revision 5 HC900 Hybrid Controller Installation and User Guide 203 9/03 Digital Input/Digital Output/Analog Outpu t RTP Internal schematic 6 7 8 9 10 20 19 18 17 16 4 5 13 12 11 3 2 1 15 14 J1 J2 J3 J4 J5 1 2 3 4 5 6 7 8 9 10 19 20 13 14 15 18[…]

-

Страница 214

Appendix B Installation of Re mote Termination Panels (RTPs) — RT P Cable wire positions and colors 204 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 RTP Cable wire positions and colors Twisted Pair Number HC900 Module TB Position RTP J1 Plug Connector Color 1 6 Black 1 2 7 Red 4 9 Black 2 5 10 White 6 20 Black 3 7 19 Green 9 […]

-

Страница 215

Appendix B Installati on of Remote Termination Pa nels (RTPs) — Latch/Unlatch RT P to rail Revision 5 HC900 Hybrid Controller Installation and User Guide 205 9/03 Latch/Unlatch RTP to rail Step Action 1 Mounting screws must be installed at each end of the mounting rail, with additional screws approx. every 8″(203mm) to preven t tw isting of th[…]

-

Страница 216

Appendix B Installati on of Remote Termination Pa nels (RTPs) — Latch/Unlatch RT P to rail 206 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03[…]

-

Страница 217

Revision 5 HC900 Hybrid Controller Installation and User Guide 207 9/03 Index —A— AC Input Module de-Rating, 40 AC Input Module Wiring, 75 AC Input terminal block, 9 AC Output Module Wiring, 80 Alarm Groups, 18 Alarm/Event messages, 14 Analog Calibration, 140 Analog Input Calibration, 141 Analog Output Calibration, 143 Analog Output Module Wiri[…]

-

Страница 218

Index 208 HC900 Hybrid Controller Installation and User Guide Revision 5 9/03 Intellution, 17 Internet Protocol, 22 IP, 22 IP address, 15 I RTD , 68 isolation capacitor, 60 IT, 22 IT networking professional, 13 —J— jumper, 63 Jumper Comb, 73, 75, 78, 80, 82 Jumper Combs, 61 jumpers, 14, 55, 56 —K— Kepware, 17 key-tabs, 64 —L— Label, 63 […]

-

Страница 219

Index Revision 4 HC900 Hybrid Controller Installation and User Guide 209 5/03 Specifications, 156 SpecView32, 17 Star topology, 22 Status, 107 Status indicator, 10 Subnet Mask , 15 Switch, 26 System Monitor Function Blocks, 45 —T— tagnames, 63 TCP/IP, 16, 22 telephone links, 12 terminal block, 57 Terminal Block Colors, 58 Terminal Block Styles,[…]

-

Страница 220

[…]

-

Страница 221

Sales and Service For application assistance, current specifications, pricing, or nam e of the nearest Authorized Distributor, contact one of the offices below. ARG E NT I N A Honeywe ll S.A.I.C. Belgrano 1156 Buenos Aires Argentina Tel. : 54 1 383 9290 ASIA PACIFIC Honeywell Asia Pacific Inc. Room 3213-3225 Sun Kung Kai Centre N° 30 Harbour Road […]

-

Страница 222

[…]

-

Страница 223

[…]

-

Страница 224

[…]

-

Страница 225

[…]

-

Страница 226

[…]

-

Страница 227

[…]

-

Страница 228

Industrial Measurement and Control Honeywell 1100 Virginia Drive Fort Washington, PA 19034 51-52-25-107 Rev. 5 0903 Printed in USA www. honeywell.com/imc[…]

-

Page 1: Honeywell HC900