Под заказ

Наши менеджеры обязательно свяжутся с вами и уточнят условия заказа

Цена действительна только для интернет-магазина и может отличаться от цен в розничных магазинах

- Описание

- Как купить

- Оплата

- Доставка

- Отзывы

- Задать вопрос

-

Дополнительно

Описание

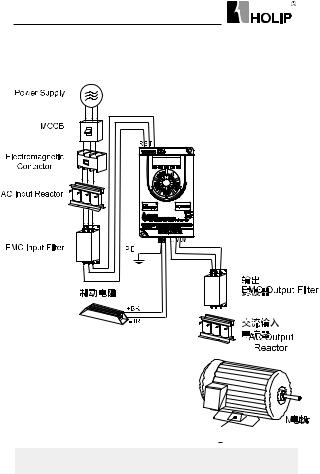

Серия HLP-A100 — это новое поколение универсальных векторных приводов Holip с высокой надежностью, высокой адаптивностью к окружающей среде, превосходным удобством для пользователя и отличными характеристиками управления.

Он может широко применяться во многих отраслях промышленности, таких как пластмасса, текстиль, станки, пищевая упаковка, химикаты, полиграфия, строительные материалы, камень, волочение проволоки, стекло, шаровые мельницы, экология, перегрузка вентиляторов и т.д.

Особенности продукта

Высокая надежность

- Длинный жизненный цикл

- Скорость вентилятора регулируется

- Строгая конструкция и тестирование производственной системы

Удобство для пользователя

- Простота в эксплуатации

- Настройка платы IO

- Небольшой размер

- Режим множественной установки

Высокая экологичность

- Независимая конструкция ветрового пути

- Покрытие PCBA 100%

- Радиатор с широким шагом зуба

- Легкая очистка и замена вентилятора

- Предусматривает опции IP5X

- Широкий диапазон напряжения

- Высокая адаптивность, характеристики EMC

- RFI переключатель

- ≥37 кВт в модели встроенного дросселя постоянного тока

- Интеллектуальная система управления отоплением

Технические характеристики

| Характеристика | Спецификация | |

| Источник питания | Напряжение питания | Однофазный / трехфазный 200 ~ 240 В -20% ~ + 10%; |

| Трехфазный 380 ~ 480В -20% ~ + 10%; | ||

| частота | 48-62Hz; | |

| Макс. несбалансированность | 3%; | |

| Мощность двигателя | Выходное напряжение | Три фазы 0-100% от напряжения питания |

| Выходная частота | V / F: 0-400 Гц, VVC +: 0-200 Гц; | |

| IO | вход | 6 цифровых входов (1 поддерживает импульсный вход, диапазон импульсов: 1 Гц ~ 100 кГц); |

| Питание | 2 аналоговых входа, оба могут принимать сигналы напряжения или тока. | |

| Контроль | ||

| Клеммы | Вывод | 2 цифровых выхода (1 поддерживает импульсный выход, диапазон импульсов: 1 Гц ~ 100 кГц); |

| 2 релейных выхода; | ||

| 2 аналоговых входа (1 можно выбрать в качестве выхода тока или напряжения через перемычку). | ||

| Источник питания | 1 + 10 В, максимальный выходной ток 10 мА; | |

| 1 24 В, максимальный выходной ток 200 мА; | ||

| связь | RS +, RS-, максимальная скорость передачи 115200 бит / с; | |

| Дисплей | 8 сегментов, 5 цифровых дисплеев | Частота отображения, предупреждения, статус и т. Д .; |

| Индикатор | Светлые FWD, REV, HZ, A, RPM отображают различные состояния привода; | |

| Считывание данных | Настройка частоты, выходной частоты, значения обратной связи, выходного тока, напряжения звена постоянного тока, выходного напряжения, выходной мощности, состояния входных клемм, состояния выходных клемм, аналогового входа, аналогового выхода, 1-10 записей о сбоях и накопленного рабочего времени и т. Д .; | |

| Окружающая среда | Ограждение | IP20; |

| Температура окружающей среды | 10 ℃ ~ 50 ℃, снижение использования при превышении 40 ℃; | |

| Влажность | 5% -85% (95% без конденсации); | |

| Вибрационный тест | ≤75 кВт: 1,14 г; | |

| ≥90 кВт: 0,7 г; | ||

| Максимум. высота над уровнем моря | 1000 м, снижение характеристик при использовании более 1000 м; | |

| Длина кабеля двигателя | Экран кабеля: 50 метров; Откидной кабель: 100 метров; | |

| Другие | Дроссель постоянного тока | ≥37 кВт встроенный |

| Тормозной блок | ≤22 кВт встроенный |

Функции продукта

| Основные функции управления | Режим управления | V / F, VVC +; |

| Пусковой момент | 0,5 Гц 150%; | |

| Перегрузочная способность | 150% 60 с, 200% 1 с; | |

| Частота переключения ШИМ | 2k ~ 16 кГц; | |

| Разрешение установки скорости | Цифровой: 0,001 Гц; | |

| Аналогия: 0,5 ‰ от макс. рабочая частота ; | ||

| Точность контроля скорости без обратной связи | 30 ~ 4000 об / мин: допуск ± 8 об / мин; | |

| Источник управляющей команды | LCP, цифровой терминал, локальная шина; | |

| Источник настройки частоты | LCP, аналоговая, импульсная, локальная шина; | |

| Управление рампой | Выбираемые 4-ступенчатые ступени: время увеличения и уменьшения 0,05–3600,00 с; | |

| Основные функции | Контроль скорости без обратной связи; Управление процессом с обратной связью; Управление моментом без обратной связи; Функция AMA; Намагничивание двигателя; Компенсация скольжения; Компенсация крутящего момента; Автоматическое регулирование напряжения; Управление V / F, Тормоз постоянного тока; Тормоз переменного тока; Ограничение скорости; Текущий предел; Быстрый старт; Функция сброса; Счетчик; Таймер; | |

| Функции приложения | Функция колебания; Многоскоростное управление через цифровой вход; SLC (включая контроль заказов и параллельное управление); Механическое торможение; ВВЕРХ ВНИЗ ; Относительное масштабирование | |

| Защита | Отсутствие защиты фазы двигателя; Низковольтная защита; Защита от перенапряжения; Защита от сверхтока; Защита от потери выходной фазы; Защита от короткого замыкания на выходе; Защита от замыкания на выходе; Тепловая защита двигателя; Функция тайм-аута в реальном времени; AMA Fails; Сбой процессора; Ошибки EEPROM; Кнопка замораживания; Повторяющиеся ошибки; LCP Invalid; LCP несовместимый; Параметр только для чтения; Ссылка вне диапазона; Неверно во время работы и т. д. | |

| Функции |

Характеристики по моделям

| Модель | Входное напряжение | Вход. ток | Вых. ток | Ном. мощность | Сила рассеивания | Расход воздуха | Нетто |

| (А) | (А) | (КВт) | (Вт) | (М3 / ч) |

(кг) | ||

| HLP-A1000D3721 | 1×200-240V | 7 | 2,5 | 0,37 | 17,7 | 51 | 1,3 |

| HLP-A1000D7521 | 1×200-240V | 13,9 | 5 | 0,75 | 33,3 | 51 | 1,3 |

| HLP-A10001D521 | 1×200-240V | 20,6 | 7,5 | 1,5 | 53,8 | 51 | 1,3 |

| HLP-A10002D221 | 1×200-240V | 30,4 | 11 | 2,2 | 75 | 51 | 1,3 |

| HLP-A10003D721 | 1×200-240V | 49,7 | 17 | 3,7 | 115,7 | 51 | 2 |

| HLP-A10005D521 | 1×200-240V | 62,4 | 25 | 5,5 | 160 | 124 | 5,6 |

| HLP-A10007D521 | 1×200-240V | 84 | 32 | 7,5 | 225 | 230 | 7,8 |

| HLP-A1000D3723 | 3×200-240V | 4 | 2,5 | 0,37 | 16,8 | 51 | 1,3 |

| HLP-A1000D7523 | 3×200-240V | 8,0 | 5 | 0,75 | 31,5 | 51 | 1,3 |

| HLP-A10001D523 | 3×200-240V | 12 | 7,5 | 1,5 | 51 | 51 | 1,3 |

| HLP-A10002D223 | 3×200-240V | 17,7 | 11 | 2,2 | 73,7 | 51 | 1,3 |

| HLP-A10003D723 | 3×200-240V | 27,2 | 17 | 3,7 | 110,9 | 51 | 2,0 |

| HLP-A10005D523 | 3×200-240V | 35,1 | 25 | 5,5 | 155 | 124 | 5,6 |

| HLP-A10007D523 | 3×200-240V | 43,4 | 32 | 7,5 | 210 | 124 | 5,6 |

| HLP-A100001123 | 3×200-240V | 61 | 45 | 11 | 323 | 272 | 7,8 |

| HLP-A100001523 | 3×200-240V | 73 | 61 | 15 | 447 | 300 | 18,5 |

| HLP-A1000D7543 | 3 × 380-440V |

3,7 | 2,3 | 0,75 | 38,5 | 51 | 1,3 |

| 3 × 440-480V | 3,2 | 2,1 | |||||

| HLP-A10001D543 | 3 × 380-440V |

6,4 | 4 | 1,5 | 49,0 | 51 | 1,3 |

| 3 × 440-480V | 5,5 | 3,6 | |||||

| HLP-A10002D243 | 3 × 380-440V |

8,9 | 5,6 | 2,2 | 65,2 | 51 | 1,3 |

| 3 × 440-480V | 7,7 | 5,1 | |||||

| HLP-A10004D043 | 3 × 380-440V |

+15,8 | 9,9 | 4,0 | 122,9 | 51 | 2,0 |

| 3 × 440-480V | 13,6 | 9 | |||||

| HLP-A10005D543 | 3 × 380-440V |

21,3 | 13,3 | 5,5 | 139,4 | 51 | 2,0 |

| 3 × 440-480V | 18,4 | 12,1 | |||||

| HLP-A10007D543 | 3 × 380-440V |

28,3 | 17,7 | 7,5 | 211,6 | 68 | 2.5 |

| 3 × 440-480V | 24,4 | 16,1 | |||||

| HLP-A100001143 | 3 × 380-440V |

35,9 | 25 | 11 | 262,4 | 124 | 5,8 |

| 3 × 440-480V | 31,4 | 22,7 | |||||

| HLP-A100001543 | 3 × 380-440V |

43,4 | 32 | 15 | 339,3 | 170 | 5,8 |

| 3 × 440-480V | 38,8 | 29,1 | |||||

| HLP-A10018D543 | 3 × 380-440V |

51,5 | 38 | 18,5 | 418,0 | 230 | 8 |

| 3 × 440-480V | 46,1 | 34,5 | |||||

| HLP-A100002243 | 3 × 380-440V |

61,0 | 45 | 22 | 468,2 | 272 | 8 |

| 3 × 440-480V | 54,5 | 40,9 | |||||

| HLP-A100003043 | 3 × 380-440V |

73 | 61 | 30 | 676,3 | 303 | 19 |

| 3 × 440-480V | 64 | 52 | |||||

| HLP-A100003743 | 3 × 380-440V |

72 | 75 | 37 | 795 | 374 | 22 |

| 3 × 440-480V | 65 | 68 | |||||

| HLP-A100004543 | 3 × 380-440V |

86 | 91 | 45 | 974,8 | 408 | 26 |

| 3 × 440-480V | 80 | 82 | |||||

| HLP-A100005543 | 3 × 380-440V |

110 | 112 | 55 | 1246 | 476 | 26 |

| 3 × 440-480V | 108 | 110 | |||||

| HLP-A100007543 | 3 × 380-440V |

148 | 150 | 75 | 1635 | 595 | 37 |

| 3 × 440-480V | 135 | 140 | |||||

| HLP-A100009043 | 3 × 380-440V |

175 | 180 | 90 | 2204 | 646 | 60 |

| 3 × 440-480V | 154 | 160 | |||||

| HLP-A100011043 | 3 × 380-440V |

206 | 215 | 110 | 2600 | 714 | 60 |

| 3 × 440-480V | 183 | 190 | |||||

| HLP-A100013243 | 3 × 380-440V |

251 | 260 | 132 | 3178 | 850 | 60 |

| 3 × 440-480V | 231 | 240 | |||||

| HLP-A100016043 | 3 × 380-440V |

304 | 315 | 160 | 3689 | 1029 | 99 |

| 3 × 440-480V | 291 | 302 | |||||

| HLP-A100018543 | 3 × 380-440V |

350 | 365 | 185 | 4268 | 1190 | 99 |

| 3 × 440-480V | 320 | 335 | |||||

| HLP-A100020043 | 3 × 380-440V |

381 | 395 | 200 | 4627 | 1292 | 99 |

| 3 × 440-480V | 348 | 361 | |||||

| HLP-A100022043 | 3 × 380-440V |

420 | 435 | 220 | 4935 | 1411 | 99 |

| 3 × 440-480V | 383 | 398 | |||||

| HLP-A100025043 | 3 × 380-440V |

472 | 480 | 250 | 5323 | 1564 | 250 |

| 3 × 440-480V | 436 | 443 | |||||

| HLP-A100028043 | 3 × 380-440V |

525 | 540 | 280 | 6543 | 1700 | 250 |

| 3 × 440-480V | 475 | 490 | |||||

| HLP-A100031543 | 3 × 380-440V |

590 | 605 | 315 | 7251 | 1870 | 250 |

| 3 × 440-480V | 531 | 540 | |||||

| HLP-A100035543 | 3 × 380-440V |

647 | 660 | 355 | 7497 | 2125 | 250 |

| 3 × 440-480V | 580 | 590 | |||||

| HLP-A100041543 | 3 × 380-440V |

718 | 745 | 415 | 8284 | 2380 | 250 |

| 3 × 440-480V | 653 | 678 |

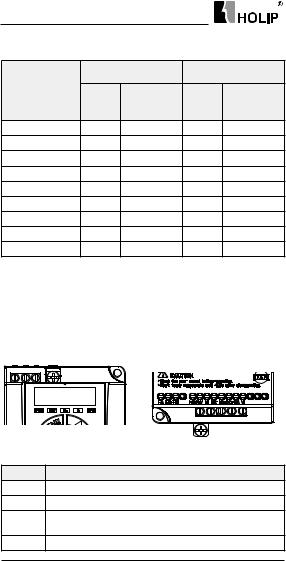

Размеры установки

| Корпус | Напряжение и питание | Размеры(mm) | ||||||||

| 1×200-240V | 3×200-240V | 3×380-480V | W | H | D | W1 | H1 | W2 | d | |

| A0 | 0.37-1.5kW | 0.37-1.5kW | 0.75-2.2kW | 125 | 210 | 152 | 104 | 194 | — | 4.5 |

| A1 | 2.2-3.7kW | 2.2-3.7kW | 4.0-5.5kW | 145 | 250 | 167 | 124 | 230 | — | 4.5 |

| A2 | — | — | 7.5kW | 155 | 263 | 177 | 133 | 243 | — | 4.5 |

| A3 | 5.5kW | 5.5-7.5kW | 11-15kW | 192 | 365 | 189 | 150 | 340 | — | 6.5 |

| A4 | 7.5kW | 11kW | 18.5-22kW | 216 | 420 | 194 | 150 | 395 | — | 6.5 |

| A5-1 | — | 15kW | 30-37kW | 292 | 517 | 229 | 240 | 492 | — | 9 |

| A5-2 | — | — | 45-55kW | 292 | 562 | 249 | 240 | 537 | — | 9 |

| A6 | — | — | 75kW | 292 | 665 | 277 | 240 | 640 | — | 9 |

| A7 | — | — | 90-132kW | 350 | 799 | 375 | 220 | 765 | 280 | 10.5 |

| A8 | — | — | 160-220kW | 486 | 900 | 390 | 345 | 863 | 410 | 10.5 |

| A9 | — | — | 250-415kW | 600 | 1568 | 509 | 424 | 304 | — | 15 |

Так же возможна поставки Аналогов Siemens

6SЕ7018-0ТА61

6SЕ7018-0ЕА61

6SЕ7021-0ТА61

6SЕ7021-0ЕА61

6SЕ7021-3ТВ61

6SЕ7021-3ЕВ61

6SЕ7021-8ТВ61

6SЕ7021-8ЕВ61

6SЕ7022-6ТС61

6SЕ7022-6ЕС61

6SЕ7023-4ТС61

6SЕ7023-4ЕС61

6SЕ7023-8ТD61

6SЕ7023-8ЕD61

6SЕ7024-7ЕD61

6SЕ7024-7ТD61

6SЕ7026-0ТD61

6SЕ7026-0ЕD61

6SЕ7027-2ТD61

6SЕ7027-2ЕD61

6SЕ7027-2ТD71

6SЕ7016-1ТА61

6SЕ7016-1ЕА61

6SЕ7016-1ТА51

6SЕ7032-1ТG50

6SЕ7032-1ТG60

6SЕ7032-1ТG70

6SЕ7032-6ТG50

6SЕ7032-6ТG60

6SЕ7032-6ТG70

6SЕ7033-7ЕG50

6SЕ7033-7ЕG60

6SЕ7033-7ЕG70

6SЕ7033-2ТG50

6SЕ7033-2ТG60

6SЕ7033-2ТG70

6SЕ7033-7ТG50

6SЕ7033-7ТG60

6SЕ7033-7ТG70

6SЕ7032-1ЕG50

6SЕ7032-1ЕG60

6SЕ7032-1ЕG70

6SЕ7032-6ЕG50

6SЕ7032-6ЕG60

6SЕ7032-6ЕG70

6SЕ7033-2ЕG50

6SЕ7033-2ЕG60

6SЕ7033-2ЕG70

6SL3224-0ВЕ25-5UА0 5.5

6SL3224-0ВЕ27-5UА0 7.5

6SL3224-0ВЕ31-1UА0 11

6SL3224-0ВЕ31-5UА0 15

6SL3224-0ВЕ32-2UА0 22

6SL3224-0ВЕ31-8UА0 18.5

6SL3224-0ВЕ33-0UА0 30

6SL3224-0ВЕ33-7UА0 37

6SL3224-0ВЕ34-5UА0 45

6SL3224-0ВЕ35-5UА0 55

6SL3224-0ВЕ37-5UА0 75

6SL3224-0ВЕ38-8UА0 90

6SL3224-0ВЕ41-1UА0 110

6SL3224-0ВЕ34-5АА0 45

6SL3224-0ВЕ35-5АА0 55

6SL3224-0ВЕ37-5АА0 75

6SL3224-0ВЕ32-2АА0 22

6SL3224-0ВЕ33-0АА0 30

6SL3224-0ВЕ33-7АА0 37

6SL3224-0ВЕ25-5АА0 55

6SL3224-0ВЕ27-5АА0 7.5

6SL3224-0ВЕ31-1АА0 11

6SL3224-0ВЕ31-5АА0 15

6SL3224-0ВЕ31-8АА0 18.5

6SL3224-0ВЕ38-8АА0 90

6SL3224-0ХЕ41-3UА0

6SL3224-0ХЕ41-6UА0

6SL3224-0ХЕ42-0UА0

6SL3224-0ВЕ22-2UА0 2.2

6SL3224-0ВЕ22-2АА0 2.2

6SL3224-0ВЕ23-0АА0 3

6SL3224-0ВЕ24-0АА0 4

6SL3210-1SЕ16-0UА0 2.2

6SL3210-1SЕ17-7UА0 3

6SL3210-1SЕ21-0UА0 4

6SL3210-1SЕ21-8UА0 7.5

6SL3210-1SЕ22-5UА0 11

6SL3210-1SЕ23-8UА0 18.5

6SL3210-1SЕ23-2UА0 15

6SL3210-1SЕ24-5UА0 22

6SL3210-1SЕ26-0UА0 30

6SL3210-1SЕ27-5UА0 37

6SL3210-1SЕ31-0UА0 45

6SL3210-1SЕ31-1UА0 55

6SL3210-1SЕ31-5UА0 75

6SL3210-1SЕ31-1АА0

6SL3210-1SЕ31-5АА0

6SL3210-1SЕ31-8UА0 90

6SL3210-1SЕ26-0АА0 30

6SL3210-1SЕ27-5АА0 37

6SL3210-1SЕ31-0АА0 45

6SL3210-1SЕ22-5АА0 11

6SL3210-1SЕ21-8АА0 7.5

6SL3210-1SЕ23-8АА0 18.5

6SL3210-1SЕ24-5АА0 22

6SL3210-1SЕ16-0АА0 2.2

6SL3210-1SЕ17-7АА0 3

6SL3210-1SЕ21-0АА0 4

6SL3210-1SЕ23-2АА0 15

6SL3210-1SЕ31-8АА0 90

6SL3225-0ВЕ31-5UА0 15

6SL3225-0ВЕ31-8UА0 18

6SL3225-0ВЕ32-2UА0 22

6SL3225-0ВЕ33-0UА0 30

6SL3225-0ВЕ33-7UА0 37

6SL3225-0ВЕ34-5UА0 45

6SL3225-0ВЕ35-5UА0 55

6SL3225-0ВЕ37-5UА0 75

6SL3225-0ВЕ31-8АА0 18

6SL3225-0ВЕ31-5АА0 15

6SL3225-0ВЕ32-2АА0 22

6SL3225-0ВЕ33-0АА0 30

6SL3225-0ВЕ33-7АА0 37

6SL3225-0ВЕ34-5АА0 45

6SL3225-0ВЕ35-5АА0 55

6SL3225-0ВЕ37-5АА0 75

6SL3244-0ВА20-1РА0

6SL3244-0ВВ12-1ВА1

6SL3244-0ВА20-1ВА0

6SЕ7011-5ЕР50/60/70

6SЕ7012-0ТР50/60/70

6SЕ7013-0ЕР50/60/70

6SЕ7015-0ЕР50/60/70

6SЕ7016-0ТР50/60/70

6SЕ7014-0ТР50/60/70

6SЕ7018-0ЕР50/60/70

6SЕ7021-0ТР50/60/70

6SЕ7021-0ЕР50/60/70

6SЕ7021-3ТР50/60/70

6SЕ7021-8ТР50/60/70

6SЕ7022-6ТР50/60/70

6SЕ7021-4ЕР50/60/70

6SЕ7022-1ЕР50/60/70

6SЕ7023-4ТР50/60/70

6SЕ7023-8ТР50/60/70

6SЕ7031-0ТЕ60

6SЕ7031-2ТF60

6SЕ7031-5ТF60

6SЕ7031-8ТF60

6SЕ7031-0ЕЕ60

6SЕ7031-2ЕF60

6SЕ7031-5ЕF60

6SЕ7031-8ЕF60

6SЕ7023-4ЕР50

6SЕ7022-7ЕР50

6SL7038-6GL84-1ВG2

6SL7038-6GL84-1JА1

6SЕ7038-6ЕК84-1GF0

6SЕ7038-2ЕН85-0АА0

6SL7038-6GL84-1НJ1

6SL7038-6GL84-1JВ0

6SЕ7038-6ЕК84-1GG0

6SЕ7090-0ХХ84-0ВD1

6SЕ7090-0ХХ84-0FЕ0

6SЕ7090-0ХХ84-0АВ0

6SЕ7090-0ХХ84-1СJ1

6SЕ7090-0ХХ84-0ВJ0

6SЕ7090-0ХХ84-4НА0

6SЕ7090-0ХХ84-0КА0

6SЕ7090-0ХХ84-0FJ0

6SЕ7090-0ХХ84-0FЕ0

6SЕ7090-0ХХ84-0FF5

6SЕ7090-0ХХ85-1DА0

6SЕ7090-0ХХ84-2FК0

6SЕ7090-0ХХ84-1СН0

6SЕ7090-0ХР87-3СR0

6SЕ7090-0ХХ84-0КВ0

6SЕ7033-2ЕG84-1JF1

6SЕ7033-2ЕG84-1FJ1

6SЕ7033-7ЕН84-1GG0

6SЕ7033-5НН84-1НН0

6SЕ7033-8ЕЕ85-0АА0

6SЕ7041-2WL84-1JС1

6SЕ7041-8НК85-1НА0

6SЕ7041-8ЕК85-1НА0

6SЕ7041-8GК85-0LА0

6SЕ7041-8GК85-0НА0

6SЕ7041-2UL84-1GG0

6SЕ7031-7НН84-1НJ0

6SЕ7031-7НG84-1JА1

6SЕ7031-2НF84-1ВG0

6SЕ7031-6ЕВ87-2DА1

6SЕ7031-2ЕР85-0АА0

6SL7032-7ЕВ87-2DА1

6SЕ7032-3ЕР85-0АА0

6SЕ7036-0ЕF85-0ЕА0

6SЕ7036-0ТК84-1ВН0

6SЕ7021-6ЕS87-2DА1

6SЕ7024-1ЕР85-0АА1

6SЕ7024-1ЕР85-0АА1

6SЕ7023-2ЕS87-2DА1

6SЕ7028-0ЕS87-2DА1

6SЕ7016-1ТА84-1НF3

6SЕ7027-2ТD84-1НF5

А5Е00454036

6DD1606-0АD0

6DD1606-0АD1

6DD1606-0АD1

6DD1606-0АD0

6DD1842-0АА1

6SY7000-0АD85

6RА7031-6DV62-0

6RА7075-6DV62-0

1FК7040-5АК71-1РА3

6SN1114-0АА01-0АА0

6SL3120-1ТЕ13-0АА3

6SL3120-1ТЕ13-0АА4

6SL3120-1ТЕ15-0АА3

6SL3120-1ТЕ15-0АD0

6SL3120-1ТЕ15-0АА4

6SL3120-1ТЕ21-0АА3

6SL3120-1ТЕ21-0АА4

6SL3120-1ТЕ21-8АА3

6SL3120-1ТЕ21-8АА4

6SL3120-1ТЕ21-8АС0

6SL3120-1ТЕ21-0АD0

6SL3120-1ТЕ23-0АА3

6SL3120-1ТЕ23-0АА4

6SL3120-1ТЕ24-5АА3

6SL3120-1ТЕ24-5АС0

6SL3120-1ТЕ26-0АА3

6SL3120-1ТЕ28-5АА3

6SL3120-1ТЕ31-3АА3

6SL3120-1ТЕ31-0АА3

6SL3120-1ТЕ32-0АА3

6SL3120-1ТЕ32-0АА4

6SL3120-2ТЕ13-0АА3

6SL3120-2ТЕ13-0АА4

6SL3120-2ТЕ15-0АА3

6SL3120-2ТЕ15-0АА4

6SL3120-2ТЕ15-0АD0

6SL3120-2ТЕ21-0АА3

6SL3120-2ТЕ21-0АА4

6SL3120-2ТЕ21-8АА3

6SL3120-2ТЕ21-0АD0

6SL3120-2ТЕ21-8АС0

6SL3130-1ТЕ22-0АА0

6SL3130-1ТЕ24-0АА0

6SL3130-2ТЕ15-0АD0

6SL3130-2ТЕ21-0АD0

6SL3130-6ТЕ21-6АА3

6SL3130-6ТЕ21-6АА4

6SL3130-6ТЕ23-6АА3

6SL3130-6ТЕ25-5АА3

6SL3130-7ТЕ21-6АА3

6SL3130-7ТЕ23-6АА3

6SL3130-7ТЕ25-5АА3

6SL3130-7ТЕ28-0АА3

6SL3130-7ТЕ28-8АА3

6SL3130-7ТЕ31-2АА3

6SL3130-6АЕ15-0АВ0

6SL3130-6АЕ15-0АВ1

6SL3130-6АЕ21-0АВ1

6SL3130-6АЕ21-0АВ0

6SL3130-0ВЕ28-0АВ0

6SL3054-0ЕН00-1ВА0

6SL3054-0DЕ01-1ВА0

6SL3054-0СG00-1АА0

6SL3040-0МА00-0АА0

6SL3040-1МА00-0АА0

6SL3040-0LА00-0АА1

6SL3040-1LА00-0АА0

6SL3040-1LА01-0АА0

6SL3040-1МА00-0АА0

6SL3310-1ТЕ32-1АА3

6SL3100-1VЕ00-0АА0

6SL3100-0ВЕ31-2АВ0

6SL3055-0АА00-2ТА0

6SL3420-2ТЕ11-7АА1

6АU1435-2АА00-0АА00

6АU1425-2АА00-0АА0

6АU1435-0АА00-0АА1

6АU1445-2АА00-0АА0

6АU1410-2АА00-0АА0

6SL3995-6LХ00-0АА0

6SЕ7024-7ТD61-Z

6SL3210-1SЕ27-5АА0

7МЕ6310-4РВ13-1НF1-Z

7МЕ6310-5DВ13-1АА1-Z

7МЕ6920-1АА30-1АА0

7МЕ6310-5RВ13-1АА1-Z

7МЕ6920-1АА30-1АА0

7МЕ6310-5КВ13-1АА1-Z

Как купить

Оформить заказ на нашем сайте легко. Просто добавьте выбранные товары в корзину, а затем перейдите на страницу Корзина, проверьте правильность заказанных позиций и нажмите кнопку «Оформить заказ» или «Быстрый заказ».

Быстрый заказ

Функция «Быстрый заказ» позволяет покупателю не проходить всю процедуру оформления заказа самостоятельно. Вы заполняете форму, и через короткое время вам перезвонит менеджер магазина. Он уточнит все условия заказа, ответит на вопросы, касающиеся качества товара, его особенностей. А также подскажет о вариантах оплаты и доставки.

По результатам звонка, пользователь либо, получив уточнения, самостоятельно оформляет заказ, укомплектовав его необходимыми позициями, либо соглашается на оформление в том виде, в котором есть сейчас. Получает подтверждение на почту или на мобильный телефон и ждёт доставки.

Оформление заказа в стандартном режиме

Если вы уверены в выборе, то можете самостоятельно оформить заказ, заполнив по этапам всю форму.

Заполнение адреса

Выберите из списка название вашего региона и населённого пункта. Если вы не нашли свой населённый пункт в списке, выберите значение «Другое местоположение» и впишите название своего населённого пункта в графу «Город». Введите правильный индекс.

Доставка

В зависимости от места жительства вам предложат варианты доставки. Выберите любой удобный способ.

Оплата

Выберите оптимальный способ оплаты.

Покупатель

Введите данные о себе: ФИО, адрес доставки, номер телефона. В поле «Комментарии к заказу» введите сведения, которые могут пригодиться курьеру, например: подъезды в доме считаются справа налево.

Оформление заказа

Проверьте правильность ввода информации: позиции заказа, выбор местоположения, данные о покупателе. Нажмите кнопку «Оформить заказ».

Наш сервис запоминает данные о пользователе, информацию о заказе и в следующий раз предложит вам повторить к вводу данные предыдущего заказа. Если условия вам не подходят, выбирайте другие варианты.

Оплата

Вы можете выбрать один из трёх вариантов оплаты:

Оплата наличными

При выборе варианта оплаты наличными, вы дожидаетесь приезда курьера и передаёте ему сумму за товар в рублях. Курьер предоставляет товар, который можно осмотреть на предмет повреждений, соответствие указанным условиям. Покупатель подписывает товаросопроводительные документы, вносит денежные средства и получает чек.

Также оплата наличными доступна при самовывозе из магазина, оплаты по почте или использовании постамата.

Безналичный расчёт

При оформлении заказа в корзине вы можете выбрать вариант безналичной оплаты. Мы принимаем карты Visa и Master Card. Чтобы оплатить покупку, вас перенаправит на сервер системы ASSIST, где вы должны ввести номер карты, срок действия, имя держателя.

Вам могут отказать от авторизации в случае:

- если ваш банк не поддерживает технологию 3D-Secure;

- на карте недостаточно средств для покупки;

- банк не поддерживает услугу платежей в интернете;

- истекло время ожидания ввода данных;

- в данных была допущена ошибка.

В этом случае вы можете повторить авторизацию через 20 минут, воспользоваться другой картой или обратиться в свой банк для решения вопроса.

Безналичным расчётом можно воспользоваться при курьерской доставке, использовании постамата или самовывоза из магазина.

Электронные системы

Для оплаты вы можете воспользоваться одной из электронных платёжных систем:

- PayPal;

- WebMoney;

- Яндекс.Деньги.

Вас перенаправит на страницу платежного сервиса, следуя инструкциям, заполните правильную форму.

Доставка

Наш интернет-магазин предлагает несколько вариантов доставки:

- курьерская;

- самовывоз из магазина;

- постаматы;

- почта России.

Курьерская доставка*

Вы можете заказать доставку товара с помощью курьера, который прибудет по указанному адресу в будние дни и субботу с 9.00 до 19.00. Курьерская служба, после поступления товара на склад, свяжется с вами и предложит выбрать удобное время доставки. Уточнит адрес.

Вы вскрываете упаковку при курьере, осматриваете на целостность и соответствие указанной комплектации. Если речь идёт об одежде, допустима примерка. Время осмотра и примерки ограничено 15 минутами. После вы можете отказаться частично или полностью от покупки.

Доставка бесплатна при заказе от 3000 рублей.

*Действует ли в вашем городе курьерская служба, уточняйте у менеджера магазина.

Самовывоз из магазина

Вы можете забрать товар в одном из магазинов, сотрудничающих с нами. Список торговых точек, которые принимают заказы от нашей компании появится у вас в корзине. Когда заказ поступит в ваш город, вам придёт уведомление. Вы просто идёте в этот магазин, обращаетесь к сотруднику в кассовой зоне и называете номер заказа. Забрать покупку может ваш друг или родственник, который знает номер и имя, на кого он оформлен.

Постамат

Постамат – это терминал с автоматизированной системой для хранения заказанных товаров. Удобство в том, что человек может забрать заказ в любое удобное время.

Как работать с постаматом:

- в момент оформления заказа на сайте, вы выбираете удобный для себя постамат, если такая система работает в вашем городе;

- на ваш телефон или e-mail придет уникальный код, это значит, что товар доставлен в постамат;

- вы приходите к постамату, вводите полученный код и следует инструкциям автомата;

- оплачиваете заказ в терминале постамата;

- забираете товар.

Срок хранения в постамате 3 дня, но можно продлить ещё на аналогичный срок. Чтобы уточнить информацию и продлить время хранения зайдите на сайт нашего партнера, введите номер заказа и телефон и следуйте подсказкам на сайте.

Почтовая доставка

Если в вашем городе не действует курьерская служба и постаматы, то вы можете заказать доставку через почту России. Сразу по прибытии товара, на ваш адрес придет извещение о посылке.

Перед оплатой вы можете оценить состояние коробки (не вскрывая): вес, целостность. Если вам кажется, что заказ не соответствует параметрам или коробка повреждена, попросите сотрудника почты составить акт о вскрытии. Вскрывать коробку самостоятельно вы можете только после того, как оплатили заказ.

Один заказ может содержать не больше 10 позиций и его стоимость не должна превышать 100 тысяч рублей.

Отзывы

Оставить отзыв

У данного товара нет отзывов. Станьте первым, кто оставил отзыв об этом товаре!

Задать вопрос

Вы можете задать любой интересующий вас вопрос по товару или работе магазина.

Наши квалифицированные специалисты обязательно вам помогут.

Задать вопрос

Дополнительно

Дополнительная вкладка, для размещения информации о магазине, доставке или любого другого важного контента. Поможет вам ответить на интересующие покупателя вопросы и развеять его сомнения в покупке. Используйте её по своему усмотрению.

Вы можете убрать её или вернуть обратно, изменив одну галочку в настройках компонента. Очень удобно.

-

Запасные части к станкам

-

Запчасти к станку 16К20 -

Запчасти к станку 1Б240, 1Б265 -

Запчасти к станку 1Н65, 1М65, ДИП 500 -

Запчасти к станку ДИП300/1М63/1М63Н -

Запчасти к станку 1Н983/СА901/1М983,1А983 (СА983), СА984, СТС630 (9М14), РТ783 -

Запчасти к станку 1512, 1516, 1525 -

Запчасти к станку 2М55, 2А554, 2А576, 2М57, 2М58, 2А587 -

Запчасти к вертикально-фрезерным станкам 6Р12, 6Р13, 6Р82, 6Р83, 6М83, ВМ-127, 6Т83, 6Т13 -

Запасные части к станкам 16В20 1В62Г 1В625 -

Запчасти к станку ИЖ250, ИТВМ, 1И611 -

Запчасти к станку 1К62, 1К62Д, 1К625 -

Запчасти к станкам 3Б722,3Д722,3Л722 -

Запчасти для колесотокарных станков КЗТС -

Запчасти к станку 2Н125, 2С132, 2Н135 -

Запчасти к станку 2К52 и 2Е52 -

Запчасти к станку 2А450 2Е450 2Д450 -

Запчасти к станку 3Г71, 3Г71М, 3Е711, 3Д711 -

Коробки передач автоматические -

Запчасти к станку 16М30 -

Запчасти к станку 1П756ДФ3 -

Запчасти к станку 16А20 -

Запчасти к станку 2620В и 2620 -

Запчасти к станку ИР-500, ИС-500 -

Запчасти к станку CU 500 (СУ-500) -

Запчасти к станкам 3М151, 3М152, 3М162, 3М163 -

Запасные части к станку ГС526У

-

-

Оснастка и комплектующие

-

Гидравлическое оборудование

-

Гидронасосы -

Гидравлические станции -

Насосы- Насосы пластинчатые регулируемые НПлР и Г12-54АМ, Г12-55АМ

- Насосы и агрегаты шестеренные Г11, АГ11, ДБГ, БГ11, ВГ11

- Насосы радиально-поршневые НП и НПР

- Насосы для подачи СОЖ

- Насосы пластинчатые для смазки С12-4М и С12-5М

- Насосы пластинчатые нерегулируемые Г12 БГ12

- Насосы пластинчатые нерегулируемые НПл

- Насосы шестеренные НШ

-

Клапаны -

Гидромоторы -

Дроссели -

Гидрозамки -

Регуляторы расхода -

Реле давления -

Пневмогидроаккумуляторы -

Гидрораспределители- Гидрораспределители золотниковые

- Гидрораспределители крановые Г71

- Гидрораспределители секционные РР, РМ, РС(Э,Г,Р,М)

- Дросселирующие гидрораспределители

-

Пневмораспределители

-

-

Запчасти части к КПО

-

Крановое оборудование

-

Электротехническое оборудование

-

Импортное оборудование

-

Металлорежущий инструмент

-

Резинотехнические изделия

-

Подшипники

-

Подшипники SKF и SLF

-

-

Запчасти к термопластавтоматам

Будьте всегда в курсе!

Узнавайте о скидках и акциях первым

| Document Information: | Share in Social: |

|---|---|

Holip HLP-A100 Series Operating manual (187 pages)

|

| Document Information: | Share in Social: |

|---|---|

Holip HLP-A100 Series Operating manual (187 pages)

|

HLP-A100 Series Operating Manual

HLP-A100 Series

HLP-A100 Series Operating Manual

IndexIntroduction 1Chapter 1 Safty Precautions 1

1.1 Before power-up 11.2 During the power-up 31.3 During the operation 31.4 After the power-off 4

Chapter 2 Standards and Specifications 52.1 Label Description 52.2 Particular Specifications 62.3 Technical Specifications 7

Chapter 3 Installation and wiring 113.1 Checks before Installation 113.2 Installation Dimensions 11

3.2.1 Dimensions of LCP 113.2.2 Dimensions of the inverter 12

3.3 Installation and Wiring 133.3.1 Electrical Installation in General 133.3.2 Fuse and Main Circuit Terminals Specifications 133.3.3 Installation and Direction 143.3.4 Wiring terminal 153.3.5 Wiring 19

Chapter 4 Operation and Display Interface 214.1 LCP Digital Operator 214.2 Quick to set parameters 21

4.2.1 Preset reference by LCP 214.2.2 FWD/REV Status 224.2.3 Data read-outs 234.2.4 View alarm record 254.2.5 View state parameter 264.2.6 LED Display 27

Chapter 5 Parameter Overview 28Chapter 6 Parameter Description 54

6.1 Parameter Group 00: Operation/Display 546.2 Parameter Group 01: Load and Motor 596.3 Parameter Group 02: Brakes 696.4 Parameter Group 03: Reference/Ramps 726.5 Parameter Group 04: Limits/warnings 816.6 Parameter Group 05: Digital Input/Output 86

HLP-A100 Series Operating Manual

HLP-A100 Series

6.7 Parameter Group 06: Analog In/Out 956.8 Parameter Group 07: Controller 1036.9 Parameter Group 08: Comm. and Options 1066.10 Parameter Group 13: Simple PLC 1106.11 Parameter Group 14: Special Functions 1186.12 Parameter Group 15: Drive Information 1236.13 Parameter Group 16: Data Readouts 1276.14 Parameter Group 25: App. Functions Cascade 1366.15 Parameter Group 30: App. Functions Wobble 145

Chapter 7 Quick Application Guide 1507.1 Motor Parameter Adaption 1507.2 Using LCP to control the drive [HAND] 1507.3 Using digital in terminals to control the drive [AUTO] 151 7.4 Set-up selection 1517.5 Potentiometer reference 1527.6 Connect two-wire transductor to terminal AI 1527.7 Reference for pulse input 1537.8 Multi-speed 1537.9 Speed up/down 1547.10 Pulse start/stop 1557.11 Digital speed up/down 1557.12 Configuration Mode 1567.13 Simple PLC 158

7.13.1 Order Execution 1587.13.2 Parallel Execution 160

Chapter 8 Accessory Specification 1618.1 Braking Resistor 1618.2 Remote Mounting Kit 162

Chapter 9 EMC 1639.1 EMC–Correct Installation 163

Chapter 10 Warnings/Alarms and Fault Handling 16410.1 Fault List 16410.2 Fault Indication and Trouble Shooting 168

Chapter 11 Maintenance 17011.1 Note 17011.2 Storage and Transport 170

Chapter 12 Communication protocol 17112.1 Format specification 17112.2 Coil addressing 17112.3 Read Coil Status 17312.4 Read Holding Registers 17412.5 Force Single Coil 175

HLP-A100 Series

HLP-A100 Series Operating Manual — 5 —

12.6 Preset Single Register 17512.7 Force Multiple Coils 17612.8 Preset Multiple Regs 17712.9 Read/Write array 17812.10 Exception code 179

HLP-A100 Series Operating Manual

HLP-A100 Series

— 6 —

HLP-A100 Series

HLP-A100 Series Operating Manual — 1 —

Caution

● Check to be sure that the voltage of the main circuit AC power supply matches the input voltage of the inverter.

● Install the inverter in a safe location, avoiding high temperature, direct sunlight, humid air or water.

● The inverter can only be used at the places accredited by our company. Any unauthorized working environment may have the risks of fire, gas explosion, electric shock and other incidents.

● If more than one drive installed on the same control cabinet, make additional cooling fan, so that the inside temperature is lower than 40℃,in order to prevent overheating or fire occurs.

● It will affect the service life of the inverter if a contactor is

IntroductionThank you for purchasing and using the general-purpose vector

inverter of HLP-A100 series.Please read caref ully the operation manual before putting the inverter

to use so as to correctly install and operate the inverter, give f ull play to its f unctions and ensure the safety. Please keep the operation manual handy for f uture reference, maintenance, inspection and repair.

Due to the inverter of a kind of power electronics product it must be installed, tested and adjusted with specialized electrical engineering workers.

The marks of (Danger) 、 (Caution) and other symbols in the manual remind you of the safety and prevention cautions during the handling, installation, running and inspection. Please follow these instructions to make sure the safe use of the inverter. In case of any doubt please contact our local agent for consultation. Our professional persons are willing and ready to serve you.

The manual is subject to change without notice.

Chapter 1 Safety Precautions

1.1 Before power-up

Caution Indicates misuse may damage the inverter or mechanical system .

Danger Misuse may result in casualty.

HLP-A100 Series Operating Manual

HLP-A100 Series

— 2 —

Danger

● Be sure to turn off the power supply before wiring.● Mount the drive in the metal and other non-combustible materials

to avoid the risk of fire.● Don’t install the drive in a space with explosive gas, otherwise,

they lead to explosion.● R, S, T terminals are power input terminals, never mixed with

U.V.W terminals. Be sure that the wiring of the main circuit is

installed on the input side to control the start and stop. Generally it is required to control it through terminal commands. Special attention should be paid to its use in the case of the start and stop more frequently places.

● Do not install any switch component like circuit breaker or contactor at the output of the inverter. If any of such components must be installed due process and other needs, it must be ensured that the inverter has no output when the switch acts. In addition, it is forbidden to install any capacitor for improvement of power factor or any varistor against thunder at the output. Otherwise it will cause malfunctions, tripping protection and damages of components of the inverter.

● Please use an independent power supply for the inverter. Do avoid using the common power supply with an electrical welder and other equipment with strong disturbance. Otherwise it will cause the drive to protect or even damage the drive.

● Motor overload protection is not included in the default settings. If this function is desired, set C01.09 (motor thermal protection) to date value ETR trip or date value ETR warning.

● Do not make any high voltage test with any component inside the inverter. These semi-conductor parts are subject to the damage of high voltage.

● The IC board of the inverter are susceptible to the effect and damage of static electricity. Don’t touch the main circuit board.

● Installation, commissioning and maintenance must be performed by qualified professional personnel.

● Don’t carry the front cover of the inverter directly when handling. It should be handled with the base to prevent the front cover off and avoid the dropping of the inverter, which may possibly cause the injuries to people and the damages to the inverter.

HLP-A100 Series

HLP-A100 Series Operating Manual — 3 —

correct. Otherwise it will cause damages of the inverter when the power is applied to it.

● The terminal of must be grounded separately and never connected to N-line. Otherwise it will easily cause the protection or errors of the inverter.

● Do not dissemble or modify any internal connecting cord, wiring or component of the inverter by yourself.

● Never remodel it or exchange control boards and components by yourself. It may expose you to an electrical shock or explosion, etc.

● Keep the inver ter from the reach of children or persons not concerned.

Caution

● Do not measure the signals on circuit boards while the inverter is running to avoid danger.

● The drive has been optimized before sold. Please make proper adjustments according to the desired functions.

● Do consider the vibration, noise and the speed limit of the motor bearings and the mechanical devices.

Danger

● Do not plug the connectors of the inverter during the power up to avoid any surge into the main control board due to plugging, which might cause the damage of the inverter.

● Always have the protective cover in place before the power up to avoid electrical shock injury.

Danger

● Never connect or disconnect the motor set while the inverter is in running. Otherwise it will cause over-current trip and even burn up the main circuit of the inverter.

1.2 During the power-up

1.3 During the operation

HLP-A100 Series Operating Manual

HLP-A100 Series

— 4 —

Caution

● Even in the case of the main power, the other voltage inputs and the share load (linkage of DC intermediate circuit) all have been disconnected from the mains, the internal of the drive still have residual energy. Before touching any potentially live parts of the inverter, please wait at least 4 minutes for the drives of less than 22KW (including 22KW), and wait at least 15 minutes for the drives of more than 30kW (including 30kW). Otherwise, it will expose you to a risk of electrical shock.

The user must strictly follow the instruction to operate and make wire connection. Otherwise HOLIP will not responsible for the damages due to wrong operation. The user will responsible for the damages themselves.

● Never remove the front cover of the inverter while the inverter is powered up to avoid any injury of electric shock.

● Do not come close to the machine when the Reset Function is used to avoid anything unexpected. The motor may automatically recover from fault.

1.4 After the power-off

HLP-A100 Series

HLP-A100 Series Operating Manual — 5 —

Chapter 2 Standards and Specifications

2.1 Label Description

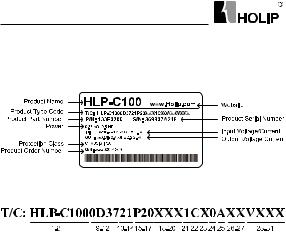

Significance of the type code:

1-8 HLP-A100 Indicate Product Series9-12 0075 Indicate 75KW 13-14 21 Indicate 1-Phase AC 220V 23 Indicate 3-Phase AC 220V 43 Indicate 3-Phase AC 380V 15-17 P20 IP rating is 2018 X Without AC choke A With AC choke19 X Without Brake unit B With Brake unit20 X Without DC choke D With DC choke21 1 Control panel with LED display and potentiometer22 C With coating on PCB 23 X Reserved24 0 Domestic sale 1 Overseas sale25-27 XX Reserved 28-31 VXXX Indicate sof tware version number, such as V235 means the version number is 2.35 .

HLP-A100 Series Operating Manual

HLP-A100 Series

— 6 —

2.2 Particular Specifications

Model Input voltageInput

current/A

Output current/

A

Rated power/

KW

Suitable motor/

KW

Net weight/

KG

HLP-A1000011433×380-440V50/60Hz 35.9 25

11 11 5.83×440-480V50/60Hz 31.4 22.7

HLP-A1000015433×380-440V50/60Hz 43.4 32

15 15 5.83×440-480V50/60Hz 38.8 29.1

HLP-A10018D5433×380-440V50/60Hz 51.5 38

18.5 18.5 83×440-480V50/60Hz 46.1 34.5

HLP-A1000022433×380-440V50/60Hz 61.0 45

22 22 83×440-480V50/60Hz 54.5 40.9

HLP-A1000030433×380-440V50/60Hz 57 61

30 30 25.43×440-480V50/60Hz 46 52

HLP-A1000037433×380-440V50/60Hz 70 73

37 37 25.43×440-480V50/60Hz 57 65

HLP-A1000045433×380-440V50/60Hz 84 90

45 45 503×440-480V50/60Hz 68 80

HLP-A1000055433×380-440V50/60Hz 103 106

55 55 503×440-480V50/60Hz 83 105

HLP-A1000075433×380-440V50/60Hz 140 147

75 75 503×440-480V50/60Hz 113 130

HLP-A1000090433×380-440V50/60Hz 175 180

90 90 603×440-480V50/60Hz 154 160

HLP-A1000110433×380-440V50/60Hz 206 215

110 110 603×440-480V50/60Hz 183 190

HLP-A1000132433×380-440V50/60Hz 251 260

132 132 603×440-480V50/60Hz 231 240

HLP-A1000160433×380-440V50/60Hz 304 315

160 160 993×440-480V50/60Hz 291 302

HLP-A1000185433×380-440V50/60Hz 350 365

185 185 993×440-480V50/60Hz 320 335

HLP-A1000200433×380-440V50/60Hz 381 395

200 200 993×440-480V50/60Hz 348 361

HLP-A1000220433×380-440V50/60Hz 420 435

220 220 993×440-480V50/60Hz 383 398

HLP-A100 Series

HLP-A100 Series Operating Manual — 7 —

2.3 Technical Specifications

Item Specif ication

Power supply

Supply voltage three phase 380-480V -20%-+10%;Frequency 48-62Hz;

Max. imbalance 3%;

Motor output

Output voltage three phase 0-100% of supply voltage;

Output f requency V/F : 0-400Hz , VVC+: 0-200Hz;

Main control

f unctions

Control mode V/F, VVC+;Start torque 1Hz 150%;

Overload capacity 150% rated output current (60s), 200% rated output current(1s);

PWM switch f requency 2K-16KHz;

Speed setting resolution

Digital: 0.001Hz; analogy: 0.5‰ of the max. operating f requency ;

Speed open-loop control accuracy 30 — 4000 rpm: tolerance±8 rpm;

Speed closed-loop control accuracy 0 — 6000 rpm: tolerance±0.15 rpm;

Control command source LCP , digital terminal, local bus;

Frequency setting source LCP , analog, pulse, local bus;

Ramp control Selectable 4-speed steps ramp up and down times 0.05-3600.00s;

Basic Functions

AMA Function; Motor Magnetisation; Slip Compensation; Torque compensation; Automatic Voltage Regulation; V/F Control, DC Brake; AC brake; Speed Limit; Cur rent Limit; Flying Start; Reset Function; Counter; Timer; PI Controller.

Application Functions

Speed Open-loop Control; Process Closed-loop Control; Wobble Function; Cascade controller; Winder; Jogging ; Multi-speed Cont rol via Digital input; Multi-speed Control via Reference; SLC ( including Order Control 、 Parallel Control ) ; Mechanical Braking;UP/DOWN;Catch up /Slow down; Relative Scaling Reference etc.

HLP-A100 Series Operating Manual

HLP-A100 Series

— 8 —

Item Specif ication

Protection Functions

Missing Motor Phase Protection; Low-voltage Protection; Over-voltage Protection; Over-current Protection; Output Phase Loss Protection; Output Short Circuit Protection; Out put Grounding Fault Protection; Motor Ther mal Protection; Live Zero Timeout Function; AMA Fails; CPU Fault; EEPROM Faults; But ton f reeze; Duplicate Fails; LCP Invalid; LCP Incompatible; Parameter Read-only; Reference Out of Range; Invalid While Running; Password Error etc.

Control Terminals

Digital input

Number 6 digital inputs.Scanning

time 1ms;

Analog input

Number of input

2 analog inputs ( VI 、 AI ) , both can receive voltage or current signals.

Input accuracy Max.error: 0.5% of f ull scale

Resolution 11bit; Scanning

time 1ms;

Pulse input

Input number

1 pulse input ( DI4 ) , pulse range:1Hz-100KHz;

Input accuracy Max.error:0.5% of f ull scale;

Resolution 11bit;Scanning

time 16ms;

Digital output

Output number 2 digital outputs ( DO1 、 DO2 )

Relay output

2 relay outputs ( KA-KB 、 FA-FB-FC ) ;

Scanning time 1ms;

HLP-A100 Series

HLP-A100 Series Operating Manual — 9 —

Item Specif ication

Control Terminals

Analog output

Output number

2 analog outputs ( VO 、 AO ) , VO can be selected to the current output or voltage output via jumper switch in the control board. AO can only be selected as current output . Up to 11 dif ferent features can be selected;

Output accuracy Max. error: 4‰ of f ull scale;

Resolution 11bit; Scanning

time 16ms;

Pulse output

Output number

1 pulse output (DO1), range: 1Hz-2KHz (range f rom 1Hz-100KHz is optional);

Output accuracy Max.error: 0.5% of f ull scale;

Resolution 11bit;Scanning

time 16ms;

Power supply

VDD 24VDC power supply;+10V 10VDC power supply;

RS485 serial

commu-nication

Terminal number 1, RS+(TX+,RX+), RS- (TX-, RX-);

Ground for RS485 GND;

Display

8 segments, 5 numeric displays

Display f requency, warnings, status and so on;

IndicatorLight FWD 、 REV 、 HZ 、 A 、 R/MIN display various status of the inverter;

Data read-outs

Frequency setting, output f requency, feedback value, output current, DC link voltage, output voltage, output power, input terminals state, output terminals state, analogue input , analogue output, 1-10 fault records and accumulated working time etc.;

Accessory

Remote mounting kit

Available when the control panel for external use;

Copy card Copy parameters f rom one inverter to another ;

HLP-A100 Series Operating Manual

HLP-A100 Series

— 10 —

Item Specif ication

Environment

Enclosure IP20;Ambient

temperature -10℃ — 40℃ ;

Humidity 5%-85% ( 95% without condensation);Vibration test ≤75KW:1.14g;90-220KW:0.7g;

Max. altitude above sea level

1000m, derating use when more than 1000 meters;

Motor cable length Shield cable: 50 meters, unshield cable: 100 meters;

OthersDC Choke ≥30kW with DC choke;Brake Unit ≤22KW with Brake Unit;

Attention: Inverter under special environment (derating) :● Derating for ambient temperature: If the f requency converter is

operated over 40℃ ambient temperature, the continuous output current should be decreased. The f requency converter has been designed for operation at max 50℃ ambient temperation with one motor size smaller than normal. Continuous operation at f ull load at 50℃ ambient temperation will reduce the lifetime of the f requency converter.

● Derating for low air pressure: The cooling capability of air is decreased at low air pressure. Below 1000m altitude no de-rating is necessary but above 1000m the ambient temperature or the maximum output current should be decreased. Dcrease the output by 1% per 100m altitude above 1000m or reduce the max. ambient temperature by 1 degree per 200m.

HLP-A100 Series

HLP-A100 Series Operating Manual — 11 —

Chapter 3 Installation and wiring

3.1 Checks before Installation

3.2 Installation Dimensions

3.2.1 Dimensions of LCP

The inver ter has been st rictly and well packed bef ore sold. In consideration of various factors during the transportation special attention should be paid to the following points before installation. If there is anything abnormal please notif y the dealer or the relevant people of our company.

● Check if the inverter has got any damage or deformation during the transportation and handling;

● Check if there is one piece of HLP-A100 series inverter and one copy of the instruction manual available when unpacking it;

● Check the information on the label to see if the specifications meet your order (Operating voltage and KW value);

● Check if the optional components you ordered are contained;● Check if there is a certificate of qualification and a warranty card.

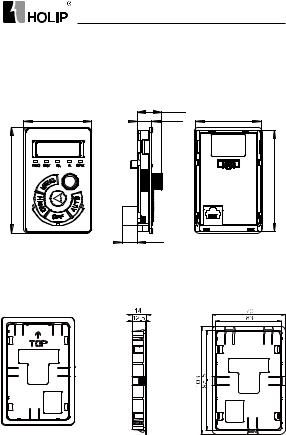

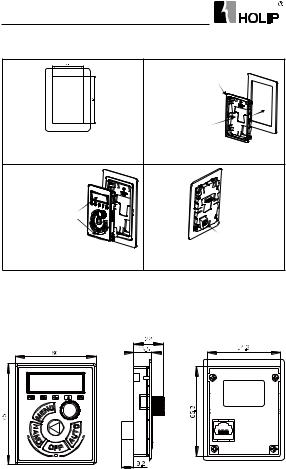

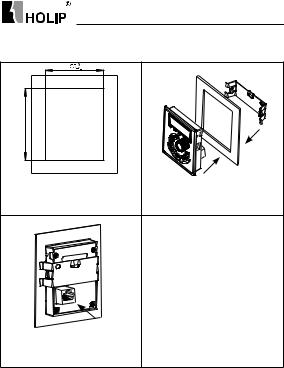

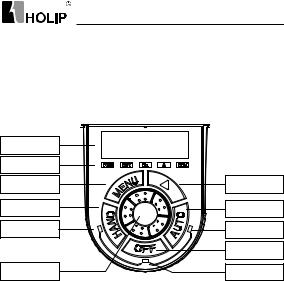

Dimensions of the LCP are shown below (unit: mm):

HLP-A100 Series Operating Manual

HLP-A100 Series

— 12 —

3.2.2 Dimensions of the inverter

Item Model Frame size and Installation Dimension

A3

HLP-A100001143

HLP-A100001543

A4

HLP-A10018D543

HLP-A100002243

A5HLP-A100003043

HLP-A100003743

A6

HLP-A100004543

HLP-A100005543

HLP-A100007543

A7

HLP-A100009043

HLP-A100011043

HLP-A100013243

A8 HLP-A100016043

HLP-A100018543

HLP-A100020043

HLP-A100 Series

HLP-A100 Series Operating Manual — 13 —

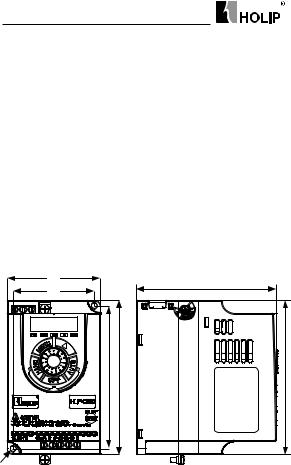

Installation dimensions of the inverter:

Details of terminal tightening torques:

3.3 Installation and Wiring

3.3.1 Electrical Installation in General

Caution

● All cabling must comply with national and local regulations on cable cross-sections and ambient temperature. Copper conductors required.

Power (KW) and Voltage levels Torque (Nm)

1×200-240V

3×200-240V

3×380-480V Line Motor DC connection/

BrakeControl

terminals Relay

11-22 1.2 1.2 1.2 0.15-0.4 0.430-75 8 8 8 0.15-0.4 0.4

90-220 16 16 16 0.15-0.4 0.4

ItemDimension(mm)

A(mm) B(mm) C(mm) D(mm) E(mm) F(mm) G(mm)A3 148 192 340 365 189 6.5 -A4 150 214 395 420 194 6.5 -A5 250 292 530 563 216.5 10 200A6 280 330 680 720 308 10.5 215A7 220 350 765 799 375 10.5 280A8 345 486 863 900 390 10.5 410

3.3.2 Fuse and Main Circuit Terminals Specifications

Model Fuse(Rated current/A) Main Circuit Terminals

HLP-A100001143 63 M4

HLP-A100001543 80 M4

HLP-A10018D543 80 M5

HLP-A100002243 100 M5

HLP-A100003043 100 M8

HLP-A100 Series Operating Manual

HLP-A100 Series

— 14 —

3.3.3 Installation and Direction

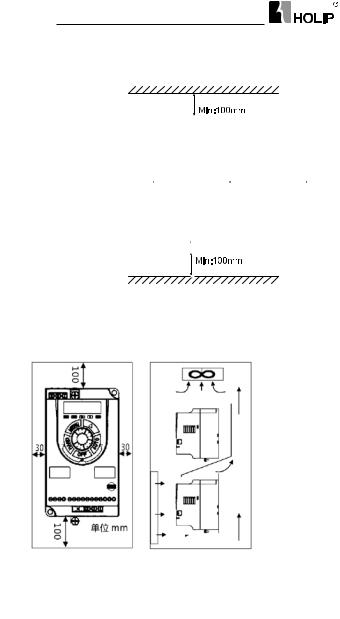

Single InstallationThe inver ter must be installed vertically with smooth ventilation. Enough space must be lef t around the inverter to ensure good cooling, as shown below:

Min:100 mm

Min:100 mm

Side by Side InstallationHLP-A100 series inver ter can be mounted side by side, a minimum space must be reserved above and below the enclosure, as shown below:

Fig.1 Single installation Fig.2 Side by side installation

Model Fuse(Rated current/A) Main Circuit Terminals

HLP-A100003743 125 M8

HLP-A100004543 160 M8

HLP-A100005543 160 M8

HLP-A100007543 224 M8

HLP-A100009043 300 M10

HLP-A100011043 350 M10

HLP-A100013243 400 M10

HLP-A100016043 500 M12*1 (M10*2)

HLP-A100018543 630 M12*1 (M10*2)

HLP-A100020043 630 M12*1 (M10*2)

HLP-A100022043 800 M12*1 (M10*2)

HLP-A100 Series

HLP-A100 Series Operating Manual — 15 —

Fig. 3 Upper and Lower installation

Upper and Lower InstallationIf several inver ters need to be installed together in one cabinet, upper and lower installation can be adopted. Enough space must be reserved to ensure effective cooling, as shown right:

Note: Install the unit and make sure that it is f ree f rom high moisture 、 high temperature 、 heavy dust 、 metal f ragments and high oil mist.

3.3.4 Wiring terminal

Min:100mm

Min:100mm

3.3.4.1 Main Circuit Terminals

Terminals of the main circuit:

11-22kW:

30-220KW:

R S T VU W-UDC +UDC

-UDC +UDC/+BR

TS U-BR R V W

HLP-A100 Series Operating Manual

HLP-A100 Series

— 16 —

3.3.4.2 I/O Control Terminals

Description of main circuit terminals:

30-75kW Control and Relay Terminals:

Symbol Function

R 、 S 、 T Power input

U 、 V 、 W Power output, connect to the motor

-BR 、 +BR Connect the brake resistor, make sure to set C02.10 、 C02.11 etc.

+UDC 、 -UDC DC bus Ground terminal

11-22kW & 90-220kW Control and Relay Terminals:

RS+ RS- FORCOM VDDREV VI AI+10V

DI2 DI3 GNDDI4 DO2DO1 VO AODCM

GND

DI1

FA FB KA FC KB

RS+ RS- AIVI REVFOR VDD DO1DI1

AO +10V DI2GND DI4DI3 DCM COMCOM

DO2

VO

KA KB

FB FCFA

HLP-A100 Series

HLP-A100 Series Operating Manual — 17 —

Description of I/O control terminals:

Symbol Description Specification

VDD 24Vpower supply

Max.load 200mA, with over load and short circuit protection f unctions;

+10V 10V power supply

Max.load 10 mA, with over load and short circuit protection f unctions;

Digital input (FOR、 REV、

DI1、 DI2、 DI3、 DI4)

Digital control terminals

1 、 Logic:PNP <DC5V logic ‘0’; >DC10V logic ‘1’;NPN >DC19V logic ‘0’; <DC14V logic ‘1’;2 、 Voltage: DC 0-24V;3 、 Input resistance: 5KΩ;4 、 Input voltage rang: max ±28V; 5 、 Switch PNP and NPN model by Jumper switch.

Analog input (VI、 AI)

Analog setting/Feedback

Set by the related parameter, analog input channel can be configurated to 0-20mA or 0-10V:Voltage input:1 、 Input impedance: about 10 KΩ;2 、 Maximum withstand voltage is 20V, duration of 2 seconds, the maximum reverse voltage is -15V , duration of 2seconds.Current input:1 、 Input impedence≤500Ω;2 、 Maximum withstand current is 29 mA duration of 2 seconds.

Analog、communication

(GND)

Analog、communication

ground

Isolated f rom internal digital ground(COM)

Pulse input DI4 Pulse setting/Feedback

1 、 Pulse input: 0.001-100.000KHz;2 、 Voltage range: 24V ± 20%;3 、 Input duty ratio: 40%-60%;

HLP-A100 Series Operating Manual

HLP-A100 Series

— 18 —

Symbol Description Specification

Digital output (DO1 、 DO2) Digital output

1 、 Open collector output;2 、 Output current range: 0-50mA;3 、 Max voltage 30V;4、 Two different way to connect relay:

V D D

D O 1

D O 2

D C M

C O M

R e la y1 R e la y2

Note: DCM and COM must be connected.

V D D

D O 1

D O 2

D C M

C O M

+ +S u p p ly

R e la y1 R e la y2

Digital output common terminal(DCM)

Digital output common terminal

Connect COM as Digital output reference ground while use.

Analog output (VO 、 AO) Analog output

VO can be selected to the current output or voltage output via jumper switch in the control board. AO can only be selected as current output:1 、 Output mode: 0-20mA or 0-10V;2 、 Voltage output: Load larger than 500Ω;3 、 Current output: Load larger than 500Ω;

Pulse output DO1 Pulse output

DO1 can also be configured as pulse output channels:1 、 Pulse output range: 0.001-5.000KHz (range f rom 0.001-100.000KHz is optional);2 、 Voltage range: 0-24V;3 、 Duty ratio: 40%-60%;4 、 Resistive load >1kΩ, capacitive load < 10nF;

HLP-A100 Series

HLP-A100 Series Operating Manual — 19 —

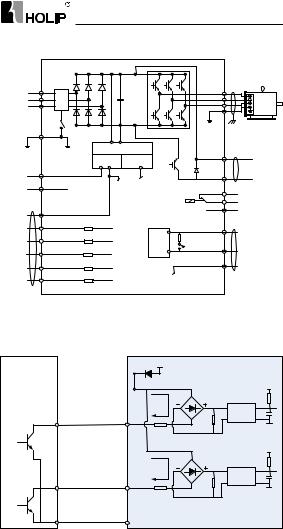

3.3.5 Wiring

Basic Connection Diagram of HLP-A100 series inverter:

Symbol Description SpecificationCOM Digital ground Isolated f rom internal GND;

Relay output (KA-KB, FA-

FB-FC)Relay output

1 、 Resistive load: 250VAC 3A/30VDC 3A;2 、 Inductive load: 250VAC 0.2A/24VDC 0.1A(cosφ=0.4);

RS+、 RS- RS485 comm-unication Max baud rate: 115200bit/s;

10V D C10M a

24V D C200M a

24V +N p N +0V +p N p +

24V +N p N +0V +p N p +

24V +N p N +0V +p N p +

24V +N p N +0V +p N p +

24V +N p N +0V +p N p +

24V +N p N +0V +p N p +

R S 485IN te Rfa Ce

p e

R

t

Sp Ow e RIN p u t

uV

w

p e

+10V

V I

a I

G N D

V D D

f O R

R e V

D I1

D O 2

D I3

D I2

D I4

C O M

+u D C

+u D C ++B R

+B R

f a

f B

f C

K a

K B

R S +

R S +

G N D

0+10V D C+4+20M a

0+10V D C+4+20M a

0+10V D C+4+20M a

D C B u S

B Ra K eR e S IS tOR

R S 485C OM M u N ICa tION

R e la y1

R e la y2

M OtOR

21

3 J u M p e RS w ItCh

R f I

R f IS w ItCh

D C M

V OltaGe O u p u t V O

a O4+20M a

D O 1

D IG Ita lIN p u t

D IG Ita lO u tp u t

t e RM IN a l R e S IS tOR

S w ItCh M OD ep Ow e R S u p p ly

C u RRe N t O u p u t

J u M p e R S w ItCh

HLP-A100 Series Operating Manual

HLP-A100 Series

— 20 —

Precautions for the main circuit wiring:● Note: The drives of more than 30kW (including 30kW) do not have +BR

and –BR terminals.● While wiring the sizes and specifications of wires should be selected

and the wiring should be executed according to the electrical engineering regulations to ensure the safety.

● It is better to use shielded wire or wire conduit for power cord and ground the shielded layer or two ends of wire conduit.

● Be sure to install a circuit Breaker between the power supply and the input terminals (R.S.T). (If using RCD, please choose B type)

● Phase-shif ting capacitors, LC, RC noise f ilters etc, can never be connected to the output terminals of the inverter.

● Please lower the inverter switching f requency when there is a longer distance between the inverter and the motor.

● Drive earth leakage current is greater more than 3.5 mA. According to the requirments of IEC 61800-5-1 , must use the following ways to enhance the protection of ground: minimum 10mm2 cross sectional area of copper, or additional PE line, its cross sectional area and the main power cable should be the same, must be separate grounded.

● Make sure reliable ground of the inverter in accordance with IEC 61800-5-1.

● Please refer to 9.2 for the use of RFI SWITCH.

HLP-A100 Series

HLP-A100 Series Operating Manual — 21 —

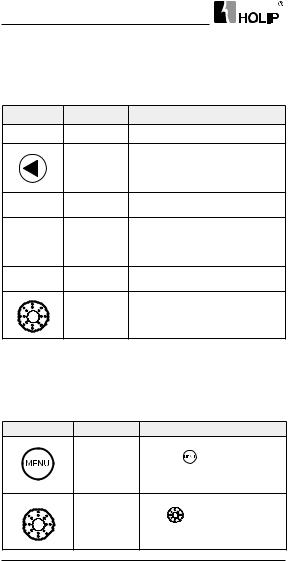

Key-press LCP Display Action Description

C00.04Press key to display the first

basic C00.03

C03.00Turn clockwise to select

parameter group C03

C03.00Press key to shif t to f ractional

part

C03.10 Turn clockwise to select parameter C03.10

Chapter 4 Operation and Display Interface

4.1 LCP Digital Operator

4.2 Quick to set parameters

4.2.1 Preset reference by LCP

Example: Set C03.10[0] to 20.5:

HLP-A100 Series Operating Manual

HLP-A100 Series

— 22 —

Key-press LCP Display Action Description

[0] Press key show the first option of C03.10

0000 Press key to show the value of the first option of parameter C03.10

000.5 Turn clockwise to change the f ractional part to 5

000.5Press key to shif t to integral

part

020.5 Press key to change the integral part to 20

END Press key to accept the change and save it as 20.5

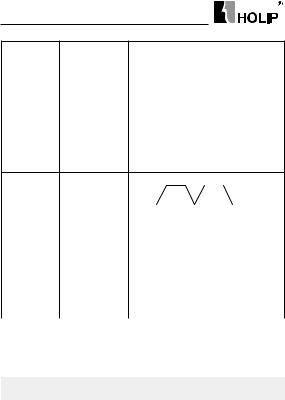

4.2.2 FWD/REV StatusConfirm the direction of the motor according to the set value, as shown

in the following table:

Reference Running status Indicator Display

≥0 STOP

<0 STOP

≥0 FWD

HLP-A100 Series

HLP-A100 Series Operating Manual — 23 —

Reference Running status Indicator Display

≥0 REV

<0 FWD

<0 REV

Note: A flash light denotes the status coming, Light on indicates the current state, and light off means not in this state.

Example 1: The f irst line of the table indicates the drive is stop and the reference is greater than or equal to 0, means the dirve at some time in the f uture will run forward.

Example 2: The fourth line of the table represents the current drive is reverse running, and the reference setting is greater than or equal to 0, it means the drive at some time in the f uture will run forward.

4.2.3 Data Read-outs

Display Items Key-press LCP Display Action Description

Output Frequency

Initial interface

Show the output f requency (C16.13) is 50.0Hz, display accuracy : 0.1

Reference (%)

Show the preset reference (C16.01) is 50%, display accuracy: 0.001

Motor Current

Show the motor current (C16.14) is 9.00A, display accuracy: 0.01

HLP-A100 Series Operating Manual

HLP-A100 Series

— 24 —

Display Items Key-press LCP Display Action Description

Motor Voltage

Show the motor voltage (C16.12) is 380.0V, display accuracy: 0.1

Motor SpeedShow the motor speed (C16.05) is 1440rpm, display accuracy:1

DC Voltage

Show the DC voltage(C16.30) is 540.0V, display accuracy: 0.1

Inverter temperature

Show the inverter temperature (parC16.34) is 45℃, display accuracy:1

Feedback Value

Show the feedback value(C16.52) is 28.000, display accuracy: 0.001

Counter AShow value of counter A is (C16.72) 65535, display accuracy : 1

Counter BShow counter B(C16.72) is 65535, diaplay accuracy : 1

Analog in VIShow analog in VI (C16.62) is 10.00V, display accuracy: 0.01

HLP-A100 Series

HLP-A100 Series Operating Manual — 25 —

Key-press LCP Display Action Description

C00.04Press key to display the first

basic C00.03.

C15.00 Turn clockwise to select par. group No. C15.

C15.00Press to select parameter

number.

C15.30 Turn clockwise to select C15.30

Display Items Key-press LCP Display Action Description

Analog in AIShow Analog in AI (C16.63) is 20.00mA, display accuracy: 0.01

Pulse InputShow pulse input (C16.68) is 50000Hz, display accuracy:1

Pulse OutputShow pulse output (C16.69) is 50000Hz, display accuracy: 1

Note: Press key to change the display items on control panel, however,

C00.33 must be activated (see C00.33).

4.2.4 View alarm record

If the drive trips, fault code will be showed to illustrate the reason, all the trip record will be saved.

HLP-A100 Series Operating Manual

HLP-A100 Series

— 26 —

Key-press LCP Display Action Description

[0] Press to show the first option of C15.30

** Press to show the first fault record.

[1]Press to show the second fault record, it can display up to ten recent

fault records in turn.

Key-press LCP Display Action Description

C00.03Press to display the first basic

parameter C00.03.

C16.00 Turn clockwise to select Par. group No. C16

C16.00 Press to select parameter No.

C16.01 Press select C16.01

0 Turn clockwise to finish browse value of C16.01.

4.2.5 View state parameter

View the status of input terminal, reference, feedback value, output f requency, output current, output voltage, and the power etc.

HLP-A100 Series

HLP-A100 Series Operating Manual — 27 —

Key-press LCP Display Action Description

C16.60 Press to select C16.60.

0000Press to view the value in C16.60, 0100 indicates status of FOR 、

DI1 、 DI2 is 0, and status of REV is 1.

4.2.6 LED Display

HLP-A100 Series Operating Manual

HLP-A100 Series

— 28 —

Chapter 5 Parameter Overview

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

Parameter G

roup 00: Operation/D

isplay

*C00.03 Regional Settings 0: 50 Hz; 1: 60 Hz; 0 54

C00.04Operating State at Power-up

0: Resume;1: Forced stop reference=old; 2: Forced stop reference=0;

1 54

*C00.06 Grid Type 0-132 * 55

C00.10 Active Set-up 1: Set-up1; 2: Set-up2; 9: Multi set-up; 1 55

C00.11 Edit Set-up 1: Set-up1; 2: Set-up2; 1 56

*C00.12 Link Set-up 0: Not linked; 20: Linked; 20 56

C00.31Custom Readout Min Value

0.00-9999.00 0.00 56

C00.32Custom Readout Max Value

0.00-9999.00 100.00 57

C00.33 LCP Display Option 0-2047 0 57

C00.40 [HAND ON] key on LCP

0: Disabled;1: Enabled; 1 57

C00.41 [OFF/RESET] key on LCP

0: Disable All; 1: Enable All; 2: Enable Reset Only;

1 58

C00.42 [AUTO] key on LCP

0: Disabled; 1: Enabled; 1 58

*C00.51 Set-up Copy

0: No copy; 1: Copy f rom set-up1; 2: Copy f rom set-up2; 9: Copy f rom factory set-up;

0 58

C00.60 Menu Password

0: Disabled; 1: Enabled; 0 58

C01.00 Configuration Mode

0: Speed open loop; 3: Process closed loop;4: Torque Open loop;

0 59

HLP-A100 Series

HLP-A100 Series Operating Manual — 29 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

Parameter G

roup01: Load/motor

*C01.01 Motor Control Principle 0: U/F; 1: VCC+; 1 59

*C01.03 Torque Characteristics

0: Constant torque; 1: Mutative; 3: Energy optim;

0 59

*C01.07Application Configuration Mode

0: No Function; 1: Wobble Function; 2: Cascade Control; 3: Winder Function;

0 60

*C01.20 Motor Power [kW][HP] Dep.on motor data kW * 60

*C01.22 Motor Voltage(Um.n) 50~1000 V * 60

*C01.23Motor Frequency(f m.n)

20~400 Hz * 61

*C01.24 Motor Current(Im.n) Dep.on motor data A * 61

*C01.25Motor Nominal Speed(nm.n)

100~9999 rpm * 61

*C01.29

Automatic Motor Adaptation(AMA)

0: Off; 1: Enabled Complete AMA; 2: Enable Reduced AMA;

0 61

*C01.30Stator Resistance(Rs)

Dep.on motor data Ω * 62

*C01.33

Stator Leakage Reactance(XI)

Dep.on motor data Ω * 62

*C01.35Main Reactance(Xh)

Dep.on motor data Ω * 62

*C01.39 Motor poles 2~100 P 4 62

*C01.42 Motor Cable Length 0~150 m 50 62

HLP-A100 Series Operating Manual

HLP-A100 Series

— 30 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

Parameter G

roup01: Load/motor

C01.50Motor Magnetisation at Zero Speed

0~300 % 100 63

C01.52

Min Speed Normal Magnetising [Hz]

0.0~10.0 Hz 0.0 63

C01.55 U/F Characte-ristic-U 0~999 V 63

C01.56 U/F Characte-ristic-F 0~400 Hz 64

C01.60Low Speed Load Compensation

0~199 % 100 64

C01.61High Speed Load Compensation

0~199 % 100 65

C01.62 Slip Compensation -400~399 % 100 65

C01.63

Slip Compensation Time Constant

0.05~5.00 s 0.10 66

C01.64 Resonance Dampening 0~500 % 50 66

C01.65

Resonance Dampening Time Constant

0.005~0.050 s 0.005 66

C01.71 Start Delay 0.0~10.0 s 0.0 66

C01.72 Start Function0: DC hold/delay time; 2: Coast/Delay time;

2 66

*C01.73 Flying start 0: Disabled; 1: Enabled; 0 67

C01.80 Function at Stop 0: Coast; 1: DC Hold; 0 67

HLP-A100 Series

HLP-A100 Series Operating Manual — 31 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

C01.82Min Speed for Function at Stop [Hz]

0.0~20.0 Hz 0.0 68

C01.90Motor Thermal Protection

0: No Protection; 1: Thermister Warning; 2: Termister Trip; 3: ETR warning; 4: ETR trip;

0 68

*C01.93 Thermister Resource

0: None; 1: Analog input VI; 6: Digital input DI4;

0 68

Parameter G

roup 02: Brake Function

C02.00 DC Hold Current 0~150 % 50 69

C02.01 DC Brake Current 0~150 % 50 69

C02.02 DC Braking Time 0.0~60.0 s 10.0 70

C02.04 DC Brake Cut In Frequency 0.0~400.0 Hz 0.0 70

C02.08 Demagnatizing Rate 0~100 % 100

C02.10 Brake Function

0: Off; 1: Resistor brake; 2: AC brake; 0 70

C02.11 Brake Resistor (ohm) Dep.on motor data Ω * 70

C02.16 AC Brake, Max current 0~150 % 100 70

C02.17 Over-voltage Control

0: Disabled; 2: Enabled; 0 71

C02.20 Release Brake Current 0.00~100.00 A 0.00 71

C02.22Activate Brake Speed [Hz]

0.0~400.0 Hz 0.0 71

C03.00 Reference Range

0: Min-Max; 1: -Max-+Max; 0 72

C03.02 Minimum Reference -4999.000~4999.000 0.000 72

HLP-A100 Series Operating Manual

HLP-A100 Series

— 32 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

Parameter G

roup 03: Reference/Ram

ps

C03.03 Maximum Reference -4999.000~4999.000 50.000 72

C03.07Main reference calculation

0: Preset reference + Reference source 1,21: Preset reference priority

0

C03.10 Preset Reference -100.00~100.00 % 0.00 73

C03.11 Jog Speed [Hz] 0.0~400.0 Hz 5.0 74

C03.12 Catch up/slow Down Value 0.00~100.00 % 0.00 74

C03.13 SpeedUp/Down Value 0.01~50.00 Hz 0.10 74

C03.14Preset Relative Reference

-100.00~100.00 % 0.00 75

C03.15 Reference Resource 1

0: No f unction; 1: Analog input VI; 2: Analog Input AI; 8: Pulse input; 11: Local bus ref; 21: LCP potentiometer;

1 75

C03.16 Reference Resource 2 2 75

C03.17 Reference Resource 3 11 75

C03.18

Relative Scaling Reference Resource

0 76

C03.19Save Speed Up/Down Value

0: No f unction; 1: Stopsave; 2: Power down save;

0 76

C03.40 Ramp 1 Type 0: Linear; 2: Sine2 ramp; 0 76

C03.41 Ramp 1 Ramp up Time 0.05~3600.00 s * 77

C03.42 Ramp 1 Ramp Down Time 0.05~3600.00 s * 78

C03.50 Ramp 2 Type 0: Linear; 2: Sine2 ramp; 0 78

HLP-A100 Series

HLP-A100 Series Operating Manual — 33 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

Parameter G

roup 03: Reference/Ram

ps

C03.51 Ramp 2 Ramp up Time 0.05~3600.00 s * 78

C03.52Ramp 2 Ramp down Time

0.05~3600.00 s * 79

C03.60 Ramp 3 Type 0: Linear; 2: Sine2 ramp; 0 79

C03.61 Ramp 3 Ramp up Time 0.05~3600.00 s * 79

C03.62 Ramp 3 Ramp down Time 0.05~3600.00 s * 79

C03.70 Ramp 4 Type 0: Linear; 2: Sine2 ramp; 0 80

C03.71 Ramp 4 Ramp up Time 0.05~3600.00 s * 80

C03.72Ramp 4 Ramp down Time

0.05~3600.00 s * 80

C03.80 Jog Ramp Time 0.05~3600.00 s * 80

C03.81 Quick Stop Ramp Time 0.05~3600.00 s * 80

Parameter G

roup 04: Limits/W

arnings

*C04.10 Motor Speed Direction

0: Clockwise;1: Counterclockwise; 2: Both;

2 81

*C04.12Motor Speed Low Limit [Hz]

0.0~400.0 Hz 0.0 81

*C04.14Motor Speed High Limit [Hz]

0.0~400.0 Hz 65.0 81

C04.18 Current Limit 0~300 % 150 81

*C04.19 Max. Output Frenquency 0.0~400.0 Hz 65.0 82

C04.21Max Output Frequency Resource

0~21 1

HLP-A100 Series Operating Manual

HLP-A100 Series

— 34 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

Parameter G

roup 04: Limits/W

arnings

C04.30Motor Feedback Loss f unction

0: No f unction; 1: Freeze output; 3: Jog; 4: Max. Speed; 5: Stop and trip; 11: Switch to open loop;

4 82

C04.31Motor Feedback Speed Error

0~600 rpm 300 82

C04.32Motor Feedback Loss Timeout

0.00~60.00 s 0.05 82

C04.50 Warning Current Low 0.00~Imax A 0.00 83

C04.51 Warning Current High 0.00~Imax A 83

C04.52 Warning Speed Low 0.0~400.0 Hz 0.0 83

C04.53 Warning Speed High 0.1~400.0 Hz 65.0 83

C04.54Warning Reference Low

-4999.000~4999.000 0.000 83

C04.55Warning Reference High

-4999.000~4999.000 50.000 84

C04.56 Warning Feedback Low -4999.000~4999.000 0.000 84

C04.57Warning Feedback High

-4999.000~4999.000 50.000 84

*C04.58Missing Motor Phase Function

0: Off; 1: On; 1 84

C04.61 Bypass Speed From [Hz] 0.0~400.0 Hz 0.0 84

C04.63 Bypass Speed To [HZ] 0.0~400.0 Hz 0.0 85

HLP-A100 Series

HLP-A100 Series Operating Manual — 35 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

*C05.02 Digital Output DO Mode 0: PNP; 1: NPN; 0 86

C05.10 Terminal FOR Digital Input

0: No operation; 1: Reset; 2: Coast inverse; 3: Coast and reset inverse; 4: Quick stop inverse; 5: DC-brake inverse; 6: Stop inverse; 8: Start; 9: Latched start; 10: Reversing; 11: Start reversing; 12: Enable start forward; 13: Enable start reverse; 14: Jog; 15: Preset ref bit0; 16: Preset ref bit1; 17: Preset ref bit2; 18: Preset ref bit3; 19: Freeze reference; 20: Freeze output; 21: Speed up; 22: Speed down; 23: Set-up select; 28: Catch up; 29: Slow down; 32: Pulse input (only available with terminal DI4 digital input) ; 34: Ramp bit0; 35: Ramp bit1; 60: CounterA (up); 62: Reset counterA; 63: CounterB (up); 65: Reset counterB; 70: Wobble start command; 71: Wobble reset; 72: Wobble initialization; 90: Low water level; 91: High water level;

8 86

C05.11Terminal REV Digital Input

10 86

C05.12 Terminal DI1 Dgital Input 15 86

C05.13 Terminal DI2 Digital Input 16 86

C05.14 Terminal DI3 Digital Input 17 86

HLP-A100 Series Operating Manual

HLP-A100 Series

— 36 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

C05.15Terminal DI4 Digital or Pulse Input

92: Scarcity water level; 93: Over run water level;

18 86

Parameter G

roup 05: Digital In/O

ut

C05.30Terminal DO1 Digital Output

0: No operation; 1: Control ready; 2: Drive ready; 3: Drive ready/Remote control; 4: Enable / No warning; 5: Drive running; 6: Running /No warning; 7: Run in rang/No warning; 8: Run on ref /No warning; 9: Alarm; 10: Alarm or Warning; 12: Out of current rang; 13: Below current, low; 14: Above current,high; 15: Out of f requency rang; 16: Below f requency, low; 17: Above f requency, high; 18: Out of feedback rang; 19: Below feed back, low; 20: Above feedback, high; 21: Thermal warning; 22: Ready, no thermal warning; 23: Remote ready, no thermal warning;24: Ready, voltage ok; 25: Reverse; 26: Bus ok; 28: Brake, no brake warning; 29: Brake ready, no fault; 30: Brake fault (IGBT); 32: Mech brake control;

0 88

C05.31Terminal DO2 Digital Output

0 88

HLP-A100 Series

HLP-A100 Series Operating Manual — 37 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

Parameter G

roup 05: Digital In/O

utC05.40

Relay Function (KA-KB,FA-FB 、 FB-FC)

36: Control word bit 11; 37: Control word bit12; 40: Out of reference rang; 41: Below ref, low; 42: Above ref, high; 51: Local ref, active; 52: Remote ref, active; 53: No alarm; 54: Start command active; 55: Running reverse; 56: Drive in hand mode; 57: Drive in auto mode; 60-63: Comparator 0-3; 70~73: Logic rule 0-3; 80: SLC digital output 1; 81: SLC digital output2; 82: SLC relay 1; 83: SLC relay 2; 84: SLC digital output 3; 85: SLC digital output 4; 90: Upto wobble limit; 91: Upto wobble ref.; 100: Start pump1; 101: Start pump2; 102: Below water level, low; 103: Above water level, high;104: Low water warning; 105: High water warning; 106: Low voltage warning; 107: Over voltage warning; 108: sleep;

5,9 88

HLP-A100 Series Operating Manual

HLP-A100 Series

— 38 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

Parameter G

roup 05: Digital In/O

ut

C05.55Terminal DI4 Low Frequency

0.020~49.999 KHz 0.020 91

C05.56Terminal DI4 High Frequency

0.021~50.000 KHz 50.000 91

C05.57Terminal DI4 Low Ref./Feedb. Value

-4999.000~4999.000 0.000 91

C05.58Terminal DI4 High Ref./Feedb.Value

-4999.000~4999.000 50.000 92

C05.59Terminal DI4 Filter Time Constant

1~1000 ms 100 92

C05.60Terminal DO1 Pulse Output Variable

0: Dgital output; 10: Output f requency; 11: Reference;12: Feedback; 13: Motor current; 16: Power; 17: Speed; 18: Motor voltage; 20: Bus control; 21: Pulse input; 22: Terminal VI input; 23: Terminal AI input;

0 92

C05.61 Pulse Output Min Freq 0.020~49.999 KHz 0.020 93

C05.62 Pulse Output Max Freq 0.021~50.000 KHz 50.000 93

C05.63 Pulse Output Min Scale 0.00~200.00 % 0.00 93

C05.64 Pulse Output Max Scale 0.00~200.00 % 100.00 93

C06.00 Live Zero Timeout Time 1~99 s 10 94

HLP-A100 Series

HLP-A100 Series Operating Manual — 39 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

Parameter G

roup 05: Digital In/O

ut

C06.01Live Zero Timeout Function

0: Off; 1: Freeze output; 2: Stop; 3: Jogging; 4: Max.speed; 5: Stop and Trip;

0 94

C06.10 Terminal VI Low Voltage 0.00~9.99 V 0.07 95

C06.11 Terminal VI High Voltage 0.10~10.00 V 10.00 95

C06.12 Terminal VI Low Current 0.00~19.99 mA 0.14 95

C06.13 Terminal VI High current 0.01~20.00 mA 20.00 95

C06.14Terminal VI Low Ref./Feedb.Value

-4999.000~4999.000 0.000 95

C06.15Terminal VI High Ref./Feedb.Value

-4999.000~4999.000 50.000 96

C06.16Terminal VI Filter Time Constant

0.01~10.00 s 0.01 96

C06.18Terminal VI Zero dead band

0.00~20.00 V/mA 0.00 96

C06.19 Terminal VI Mode

0: Votage mode; 1: Current mode; 0 97

C06.20 Terminal AI Low Voltage 0.00~9.99 V 0.07 97

C06.21 Terminal AI High voltage 0.01~10.00 V 10.00 97

C06.22 Terminal AI Low Current 0.00~19.99 mA 0.14 97

C06.23 Terminal AI High Current 0.01~20.00 mA 20.00 98

C06.24Terminal AI Low Ref./Feedb.Value

-4999.000~4999.000 0.000 98

HLP-A100 Series Operating Manual

HLP-A100 Series

— 40 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

Parameter G

roup 05: Digital In/O

ut

C06.25Terminal AI High Ref./Feedb.Value

-4999.000~4999.000 50.000 98

C06.26Terminal AI Filter Constant

0.01~10.00 s 0.01 98

C06.28Terminal AI Zero dead band

0.00~20.00 V/mA 0.00 98

C06.29 Terminal AI Mode

0: Voltage mode;1: Current mode; 1 99

C06.70 Terminal VO Mode

0: 0-20mA; 1: 4-20mA; 3: 0-10V; 3 99

C06.71Terminal VOAnalog Output

0: No operation; 10: Output f requency; 11: Reference; 12: Feedback;13: Motor current; 16: Power; 17: Speed; 18: Motor voltage; 20: Bus control; 21: Pulse input; 22: Terminal VI; 23: Terminal AI;

0 99

C06.73Terminal VO Output Min Scale

0.00~200.00 % 0.00 100

C06.74Terminal VO Output Max Scale

0.00~200.00 % 100.00 100

C06.81 LCP Potmeter Low Ref. -4999.000~4999.000 0.000 100

C06.82 LCP Potmeter High Ref. -4999.000~4999.000 50.000 101

C06.90 Terminal AO Mode

0: 0~20mA; 1: 4~20mA; 0 101

C06.91Terminal AO Analog output

See also C06.71. 0 101

HLP-A100 Series

HLP-A100 Series Operating Manual — 41 —

Item Parameter No.

Function Description Setting range Unit Default

settingPage No.

C06.93Terminal AO Output Min Scale

0.00~200.00 % 0.00 101

C06.94 Termianl AO Max Scale 0.00~200.00 % 100.00 102

Parameter G

roup07: Controllers

C07.12Torque PI Proportional Gain

0~500 % 100

C07.13Torque PI Integration Time

0.002~2 S 0.02

C07.20Process CL Feedback Resource

0: No Function; 1: Analog in VI; 2: Analog in AI; 8: Pulse input; 11: Local bus;

0 103

C07.30

Process PI Normal/Inverse Control

0: Normal; 1: Inverse 0 103